- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- crushing plant

Results for

Crushing plant - Import export

PI MAKINA

Turkey

Pi Makina, which has produced the largest Crushing and Screening Facilities in Turkey and the world, produces solutions suitable for every project and need. Pi Makina has installed hundreds of crushing and screening plants around the world and uses its experience in this sector in every new project to offer superior performance facilities tailored to customers' wishes. Pi Makina, which produces any equipment that may be necessary for a crushing and screening plant through its own designs, has a wide range of products such as cone crusher, vertical shaft impact crusher, hammer crusher, jaw crusher, screen sand washer and mobile crushing plant.

Request for a quote

OPT MAKINE

Turkey

Jaw crushers are the type of crushers used to reduce big-size rocks by compression, i.e. by mechanical pressure applied by two jaws of the crusher. These crushers are used as primary and secondary crushers in crushing plants. Jaw crushers are mostly preferred crushers because of their ability to crush all kinds of materials of any hardness. Our jaw crushers assures low and easy operation & maintenance cost. Our range of jaw crushers includes 6 different types of Primary and Secondary jaw crushers from 610 x 380 mm type to 1300 x 1100 mm mouth opening. The high performance, reliability, durability and user-friendly adjustment mechanisms of our jaw crushers due to their high flywheel speeds, jaw grabbing angles, special geometries of their pits with safety plates and rear blocks provide unique operating advantages to its users.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UGURMAK UMG Series Vibratory Grizzly Feeders are the main feeder type used in crushing and screening plants. They take place for feeding jaw or impact crushers used in primary stage. Offering high performance even in the harshest conditions, UMG Series feeders can be used for any size of material, from oversized material to small size stream materials. Thanks to the adjustable grill distance, the product size that cannot be included in the primary stage can be changed. It has a very solid chassis. Feeder body is seated on it with helical springs in sufficient number and strength. On this feeder body, there is a large volume bunker in the structure offering high strength. It can be used in all mobile and stationary primary units.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

As a crushing and screening company, we should consider our crawler crusher as both a crushing plant and the wonderful collaboration of all it’s components. Its easy movement and breaking of all natural rocks, Concrete and asphalt wastes are the determining roles in its selection.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK CDK Series Primary Impact Crushers have a design that allows the rotor, two pendulum systems and wear plates to work in harmony. Thanks to this compatibility, it offers high performance and low operating costs. It can provide very high size reduction ratios in breaking not very hard and non-abrasive materials. Thanks to these advantages, they are preferred in primary crushing stage in crushing and screening plants. According to the design of the facility, they can be manufactured as mobile, with fixed steel legs, with fixed concrete legs, with fixed skid chassis.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK brand SMK Series Secondary Impact Crushers can crush medium and high hardness materials such as limestone, dolomite, granite and basalt to the size of asphalt and concrete aggregate. Large size material from the primary crusher can be fed directly. High reduction rate is provided. It is the most preferred secondary crusher type in crushing and screening plants since the initial investment and operating costs are lower than other crusher types. According to the design of the facility, they can be manufactured as mobile, with fixed steel feet, with fixed concrete feet, with fixed skid chassis, pre-screened or pre-fed.

Request for a quote

NOVELTY STEEL

Turkey

Mobile crushers are mounted on a self-propelled steel platform equipped with wheels, crawlers, or pneumatic pads for movement. The platform incorporates all necessary auxiliary equipment and subsystems for crusher operation. They operate independently on the mine floor. Placed at the working face, the crusher minimizes the need for truck or front-end loader transport, with planned moves occurring between one day and one week. Installation of mobile crushing plants is advantageous under specific conditions; * A clear and undisturbed geological situation, * Straight and long benches for shiftable face conveyor installation, * Long-term mine planning for various conveyors. The benefits of fully-mobile crushers include * Elimination of truck transport * Reduced personnel requirements * Avoidance of high truck maintenance costs * Decreased mine traffic * Overall improvement in mine safety.

Request for a quote

NOVELTY STEEL

Turkey

The primary crusher selection is the key to the success of the mining, quarrying or industrial minerals operation that involves the reduction in size of rock, ore or minerals. The crushing plant can be provided with almost any type of primary rock crusher. Novelty Steel supplies; * Cone Crushers * Jaw Crushers * Gyratory Crushers * Impact Crushers * Mobile Crushers

Request for a quote

MPN - MECÂNICA DE PRECISÃO DO NORTE, LDA.

Portugal

DESIGN - MANUFACTURE - INSTALLATION - COMMISSIONING COMPLETE INSTALLATIONS MINING - QUARRYING - RECYCLING

Request for a quote

MPN - MECÂNICA DE PRECISÃO DO NORTE, LDA.

Portugal

Extraction, crushing and grinding plants and their consumables: mills, hoppers, gutters, screens, trellises, conveyor belts, drums, rollers, fences, geared motors, buildings, supports, crushers, passageways, ladders, guardrails…

Request for a quote

ECSMT MACHINERY EQUIPMENTS

Turkey

ECMT RUROMIX EM130 CRAWLER MOBILE COUNTERATTACK CRUSHER STATION Strong and stable, Best quality, Long service life and low operating cost, Effectiveness and efficiency.

Request for a quote

ZHIVANA ORGANICS

Ukraine

Nettle or stinging nettle has a scientific name Urtica dioica. Different parts of the plants such as leaves, stem, or root from the nettle plant can be crushed and used into powders, tinctures, creams and teas. People have widely used nettle for centuries as a herbal medicine. Contemporary scientific research supports the potential health benefits of this plant. Nettle I known to reduce inflammation, treat hay fever, lower blood pressure, help control blood sugar.

Request for a quote

SEDA MAKINA IMALAT TIC LTD STI

Turkey

USED CRUSHING AND SCREENING PLANT FOR SALE PRIMARY IMPACT CRUSHER (160 t/h) SECONDARY IMPACT CRUSHERS (16/18 and 12/12) SCREENS (150/4000, 220/6000 and 120/3000) STOCK PILE (100 t) CONTROL PANEL DUST COLLECTOR

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The HammerKnife Universal Mill is the combination between a Hammer Mill and an Universal Mill. As the FORPLEX FNG Mill it can be equipped with different grinding tools (hammer plate ou blade plate) which are adjustable in relation to the product to be ground. The FK Mill has the same advantages as the Universal Pin Mill FNG easy to use, easy to clean, easy to maintain, but also simplicity of changing the grinding tools or grids. Perfect for technical applications such as the grinding of natural ingredients (knife rotor designed for the crushing of plants), the FK mill was designed to meet the standards of the foodstuffs industry, fine chemicals industry, pharmaceuticals industry, nuclear industry or even for cosmetics. It can meet FDA, GMP or ANIA standards and criteria. With the robustness and strength of hammer crusher

Request for a quote

TEKNO MILLING MACHINES CO. LTD

Turkey

As Tekno Milling Machines Co. Ltd that founded in Mersin Turkey, we offer turnkey completed seed,pulses,cereals,nuts,spices processing screening crushing and cleaning plants also following agricultural machines and spare parts. Seed Cleaning and Processing Machines : Pre-Cleaning Machines,Classical Screening Machines,Excel Cleaners,Destoners,Gravity Separators,Indent Cylinders,Brushing Machine,Liquid Treatment Machines,Color Sorting Machines,Bagging Machines,Dehullers,Millers Packaging machines: Vertical packaging machines,Rotary Type Packaging Machines,Filling Machines,Seed Counting Machines,Bailing Machine Post Packaging Systems: Carton Packing Machines, Streching Machines ,Shrinking Machines,Vacuum Machines,Metal Dedectors,Printers,Carton Coding Machines,Sticking Machines Silo Systems : Elevators,Conveyor Belts,Screw Conveyors,Silo Systems Please visit our website for all.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OFFICINE CONTERNO SRL

Italy

Officine Conterno designs and manufactures crushing, screening and aggregate washing plants for the production of concrete, bituminous conglomerates, road foundations or railway ballast. Jaw crushers, primary, secondary and tertiary mills, feeders, rotating screens, vibrating screens, vane or barrel scrubbers, and cyclonic separation groups ... These are just some of the machines in our product range.

Request for a quote

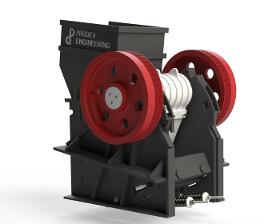

PRODEV ENGINEERING

Turkey

Can crush any hardness material. Thanks to the mechanism of the jaw crusher that high amount of mechanical pressure created by two jaws, one of which is fixed and the other making an elliptical movement, it can easily crush large stones of any hardness. Thanks to this feature, it is the most preferred crusher type in crushing and screening plants. Elliptical movement is provided by the eccentricity of the shaft to which the movable jaw is attached. This elliptical flow movement created allows the material to be fragmented between the fixed jaw and the movable jaw. High Performance Thanks to the design of the crushing chamber in jaw crushers, even in mines with high abrasiveness, less wear occurs compared to impact crushers. In this way, jaw crushers offer long-lasting working performance. Jaw crushers allow processing of larger material than impact crushers. It also works with high capacity at low motor powers. This ensures high working efficiency.

Request for a quote

HAVER NIAGARA GMBH

Germany

HAVER & BOECKER stands for expertise and best Performance. The scalper is one of the main components of each primary crushing plant. With the scalper your plant will be more efficient, low-wear and more productive. HAVER NIAGARA® eccentric screening machines are perfect for scalping because of their heavy-duty design and smooth running. We combined our experience since 1930 with the supplementary components of our suppliers and realize complex plant projects according to our customers needs. We engineer plants according to your specifications As the market leader in eccentric screening technology, HAVER & BOECKER provides expertise pre-crushing systems as well as secondary and tertiary crushing. We will work with any crusher and peripheral component manufacturers. Basic Master Components Service Advantages References Basic Pre-crushing Plant Basic The classic pre-crushing plant serves to relieve the primary crusher by using a HAVER NIAGARA eccentric screening machine. If.

Request for a quote

HAVER NIAGARA GMBH

Germany

The NIAGARA® scalper is the best choice for crushing plants or the classification of coarse and difficult-to-screen materials at high throughput rates and fluctuating material feed rates. The unique NIAGARA® drive system generates a constant circular vibration motion at a fixed amplitude. The amplitude remains unchanged over time, no matter what the material load is. The application area of the NIAGARA® Scalper covers a variety of industries and materials with a length of up to 2000 mm and a cut size of 2 - 450 mm. Advantages reduced loads and energy demands for the subsequent crushing plant increased crusher capacity maximising the quality of the crushed product quick and easy re-balancing is always possible built with long-life bearings maintenance-friendly, modular machine design dynamically balanced construction modernisation of existing plants, performance improvement You’ll find detailed information in our product brochures and specification sheets.

Request for a quote

HAVER NIAGARA GMBH

Germany

Complex plant projects with multiple components and planning phases require comprehensive experience and expertise in plant integration. HAVER & BOECKER links our core screening, washing and pelletizing technologies with supplementary components of our vendors. The North American mineral processing brand W.S. Tyler is also a part of HAVER & BOECKER. Tyler technology can be implemented into your plant. HAVER & BOECKER offers the “single source” principle where a single contractor takes over full responsibility for project execution. Engineering knowledge, modern systems integration and software solutions provide the basis for successful planning and implementation. Building a plant with our customers is a mutual partnership. The processing specifications and needs of our customers, in combination with our global experience, are the keys to achieving a profi table mineral processing plant. Screening and Crushing Plants Washing Plants Pelletizing Plants Screening and Crushi

Request for a quoteResults for

Crushing plant - Import exportNumber of results

23 ProductsCompany type

Category

- Crushing and grinding machinery (14)

- Turning - steels and metals (3)

- Agriculture - Machines & Equipment (1)

- Building materials, manufacture - machinery and equipment (1)

- Compactors and crushers (1)

- Concrete constructions (1)

- Flour milling - machinery and equipment (1)

- Flowering plants (1)

- Mining and quarrying - machinery and equipment (1)