- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting of tubes

Results for

Cutting of tubes - Import export

TRANSFLUID® MASCHINENBAU GMBH

Germany

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money. Technical specifications: Separation efficiency: max. Ø 28 x 2 mm for stainless steel tubes Shortest separation length: — 25 mm (without pull apart) — 55 mm (with pull apart) Separation efficiency: up to 2,000 pcs per hour

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg as a professional metal parts manufacturer from China, provide various metal fabricating services by ourself and our brother factories. Now,our brother factory has introduced 2 set tube laser cutting machines, provide tube laser cutting services for us, we can custom tube fittings easily and faster without develop molds. Technical parameters of tube laser cutting service: Cutting Diameter:15mm – 150mm Cutting Length:6.2m Accuracy: +/-0.1mm Cutable materials: Carbon Steel Pipe, Stainless Steel Pipe, Aluminum Pipe, Brass or Copper Pipe Tube Structures: Round, Square,Hexagon With our metal stamping service, we can produce a variety of pipe accessories, such as shrinking and flaring pipe fittings. Welcome inquire us!

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The chain manipulation system is the system of choice for rotationally symmetrical geometries, especially pipes. The chain enables flexible application on external diameters between 400 and 1500 mm.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

Our specialist-built cutting shop is fully equipped to suit your needs. In addition to our laser cutting facilities, we have a bank of fully automatic and semi-automatic cutting machines ready to process materials up to 3,000mm in length. With the capability to hold tight tolerances (+/- 0.20mm) on diameters ranging from 6mm - 153mm, our cutting services are the cost-effective option for high volume repetitive cut orders. Whether you choose the built-in deburring and washing options or the stand alone alternatives available alongside the cutting service, your components will be completed to a high standard of finish.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Created for precision. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can then be directly processed further and for instance be formed straight afterwards. That saves time and money.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money. Technical specifications: Separation efficiency: max. Ø 50,8 x 2,5 mm Shortest separation length: - 25 mm (without pull apart) - 55 mm (with pull apart) Separation efficiency: up to 2,000 pcs per hour

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

Our laser tube cutting service includes all major tube and section profiles – including large tube laser cutting – with specialist profile capabilities accommodated with ease. Continuous investment ensures we can always offer our customers the broadest capabilities, so they remain at the forefront.

Request for a quote

MONGIN

France

CUTTING AFTER TUBES FILLING TYPE OF MACHINES : UNIPAC, TONAZZI, KALIX, AXIOMATIC, ... On your tube fillers lines, once tubes filled and sealed, they are cut using a knife and a counter knife. N°1 Counter knife UNIPAC N°2 Knife UNIPAC N°3 Moving blade TONAZZI N°4 Fixed knife TONAZZI N°5 AXIOMATIC cutting die

Request for a quote

MONGIN

France

Cutting after tubes filling N°1 - Blade N°2 - Counter blad

Request for a quote

METAL IN LTD

Bulgaria

Metal In put into operation a machine for laser cutting of pipes with automatic loading and unloading. The size of the treated pipes is: Round pipes: 120 mm Rectangular tubes: 100x100mm The maximum length of the workplace is 6500mm. The machine is equipped with excellent software that allows different shapes in tubes for subsequent assembly and welding. Also, pipes can be cut so that one wall remains uncut, allowing it to bend easily and accurately and find a frame.

Request for a quote

DOREY

France

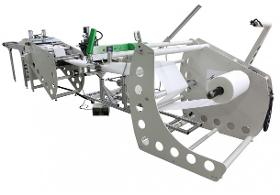

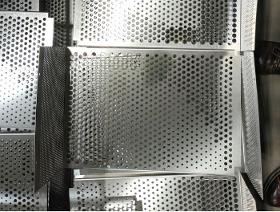

The new Miller Weldmaster filter tube line uses our experience from our previous filter systems and introduces revisions that will make filter tube production even easier. This system makes loading your material easier by giving a laser guideline to help ensure the roll is positioned properly which makes set up easier. From the unwind your material will be guided into the heat seamer with the help of a pre fold system and an adjustable tubing guide which will help you make perfect diameter tubes. The tube will then be brought into the conveyor cutter system which will cut the tubes to the exact length you need and our newly designed sweep system will allow you to push your finished tubes off the side into a take away bin. FEATURES, FUNCTIONS, & BENEFITS No operator involvement reducing labor. It is capable of welding up to 90 feet per minute depending on the fabric which will help increase production.

Request for a quote

DOGRAR METAL

Turkey

Tube and section laser cutting provides many advantages such as new design opportunities, declining manufacturing steps or easier welding methods from machinery to furniture sector. Thanks to Trumpf TruTube 3000 Fiber that we have included in our machiner in 2021. we can process tubes and sections up to 170 mm diameter or side dimensions. Laser cutting of tubes and sections, used in a wide range from the machinery industry to the furniture industry, offers you new pipe and profile construction possibilities that cannot be realized with traditional methods in pipe and profile construction. All kinds of contours and shapes that cannot be made with traditional methods are achieved with laser with low tolerances and at the same time saving time. In addition to the ease of processing, you can also simplify further manufacturing steps with the created contours. For example, with the positioning aids obtained by creating male and female contours on opposite sides

Request for a quote

MICRON AMERICA

Turkey

The frame is made of highly polished steel and the cutting dies are simply pushed in for easy replacement. Replacement cutting tubes are also available.

Request for a quote

PEEKCHINA CO., LTD.

China

1/16 Inch Bending PEEK Tubing In the world of fluid handling and precision engineering, the choice of tubing can make all the difference. When you demand exceptional performance, reliability, and versatility, look no further than our 1/16 inch PEEK tubing. Engineered with precision and crafted from high-quality materials, this tubing is the perfect solution for a wide range of applications, from laboratory experiments to industrial processes.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Clean, efficient, versatile. transfluid's knife cutting method is ideal for postbending cuts. Even with extreme geometries it is possible to have perpendicular cuts with sharp edges. In both cases both chips can easily be detected in the process. Extreme requirements are also not a problem, as up to two blades can be used. An internal mandrel can also optimise the process.

Request for a quote

KW HYDRAULIK GMBH

Germany

Cutting and Sawing of Tubes

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TRANSFLUID® MASCHINENBAU GMBH

Germany

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money. Technical specifications: Separation efficiency: max. Ø 105 x 3 mm Shortest separation length: - 100 mm (without pull apart) - 170 mm (with pull apart) Cycle time: 5-10 sec. (depending on material, diameter, wall thickness and cutting length)

Request for a quote

KW HYDRAULIK GMBH

Germany

Pressing Pipes Bending Pipes Striping and Peeling of Tube Brochure Tools for Pipeline Construction Drilling of Tubes Cutting and Sawing of Tubes Chamfering Tool for Plastic Tubes

Request for a quote

ROHRE-KETTERER GMBH

Germany

Cutting or sawing tubes to required lengths is often only the beginning of multiple treatments necessary on the way to a finished part. We can offer machining fulfilment no matter if your parts have to be milled out, drilled or worked. Or have to be stucked and need a thread insert or durface treatment.Or all of this together. Our samples show you a range of the possibilities we have to fulfill your needs.

Request for a quote

ROHRE-KETTERER GMBH

Germany

is a cutting method that can be used for all material grades. The quality of the cut is superior to other cutting technolgies in precision, rectangularity and it is nearly burr-free. The result of the top quality machined surface is an optimized further processing of the parts especially if they have to be welded or soldered. Often there is no need to deburr the parts after the cutting. We cut with high precision and nearly burr-free on especially developed cutting units any geometry of tubes also shaped and manipulated parts without deforming the parts.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Fewer steps to the finished workpiece With t project you can see all the variables of the bending process before you start the production. Adapted to the material and collisionfree, it makes it possible to plan and execute complex bending geometries. The virtual bending simulation determines exact bending timings and cutting lengths; it also tests tube geometries in advance for feasibility. Tube data and bending results are documented with accuracy and they can then be replicated 100% . All the most common interfaces are available for the import and export of data and connection to BDE or ERP over the network.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

In form, double strength. For the optimum processing of your individual requirements we simply combine our transfluid forming techniques, as simple as that, in particular the axial forming and the rollforming. The additional clamping unit makes even extreme forming feasible in one work sequence. The cutting before the axial tube forming is also possible, as well as the rollforming of a preformed geometry. That saves you valuable time. A strong partnership axial forming and rollforming. Our t form combination machines is the perfect union of axial and rolling tube processing, with up to 6 axial forming steps, two rollforming stations, two powered tool holders for flange orientation and an additional clamping unit. The horizontal clamping system makes the processing of bent tube geometries possible.

Request for a quote

ESTIMET SP Z O.O.

Poland

One of the areas of ESTIMET's offer is laser cutting, used for precision processing of sheet metal, pipes and profiles. In ESTIMET's machine park we have two fiber lasers of 6 kW and 8 kW. Thanks to these devices, we can precisely cut elements with maximum dimensions of 2000 x 4000 mm. Our laser cutting services comply with the EN 1090 standard, as confirmed by the CE mark. We are ready to take on even the most demanding orders, offering to cut sheet metal made of a variety of materials, such as carbon steel, stainless steel, aluminum, copper or bronze. We also have a gas burning machine, dedicated to metal sheets up to 150 mm thick. In addition, we have specialized machines for cutting pipes, profiles and sections with maximum dimensions of 450 x 450 mm. We can cut tubes and profiles in straight sections as well as at an angle. The range: steel: 0,5 - 25 mm INOX: 0,5 - 30 mm aluminum: 0,5 - 25 mm brass: 0.5 - 10 mm copper: 0.5 - 10 mm galvanized: 0.5 - 4 mm

Request for a quote

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

AMETEK EMC has been manufacturing in the orthopedic device market for decades. With regular technology improvements, we’ve adapted to the latest capabilities. Precision cutting of tube and sheet as well as precision welding with lasers is the key to our capabilities.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Tube Components Manufacturer Custom Metal Tube Handles Of Aluminum Alloy, Carbon & Stainless Steel Tubes Tube end forming: A forming process used to create a specific end, usually to allow the tube to connect to another media. Cutting: The cutting process allows for metal tubes to be cut into specific shapes and sizes. Examples include tube laser cutting and mechanical cutting. Notching: This process creates notches at the end of the tube to simplify welding processes or to attach the tube to another part. Swaging: Swaging uses a die to manipulate the size of the tube diameter using force. Custom Metal Tube Forming Components, Seat Frame, Tube Handle, Yacht barrier... sales@mxmparts.com

Request for a quote

ELEKTRON SP. Z O.O.

Poland

We provide laser cutting services for stainless steel, black steel, and aluminum sheets. We cut details both from our own material and from the material supplied by our customers. 3D laser cutting of pipes and square profiles — our offer. • 3D Laser cutting of pipes with a diameter of 20 to 210 mm and a maximum length of up to 6,500 mm (maximum pipe cutting length of 6,000 mm), • 3D Laser cutting of square profiles 20 × 20 and 150 × 150 with a length of up to 6500 mm, • 3D laser cutting of other tubes with a diameter not exceeding 210 mm (e.g., 150 × 20 mm). The maximum thickness of the material: • Aluminum: up to 3 mm • Stainless: up to 5 mm • Copper: up to 2 mm • Steel: up to 8 mm • Brass: maximum thickness up to 3 mm we can significantly simplify the entire cutting process and, at the same time, obtain profiled elements that are 100% repeatable. Please send your inquiry to the following e-mail address: laser@web-elektron.pl

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Tube end forming: A forming process used to create a specific end, usually to allow the tube to connect to another media. Cutting: The cutting process allows for metal tubes to be cut into specific shapes and sizes. Examples include tube laser cutting and mechanical cutting. Notching: This process creates notches at the end of the tube to simplify welding processes or to attach the tube to another part. Swaging: Swaging uses a die to manipulate the size of the tube diameter using force. Custom Metal Tube Forming Components, Seat Frame, Tube Handle, Yacht barrier... sales@mxmparts.com

Request for a quote

ELEKTRON SP. Z O.O.

Poland

One of our major services is the laser cutting of pipes and tubes. 3D laser cutting creates completely new possibilities when it comes to the speed of cutting as well as the precision of the materials in which it can be used. We use the most advanced machinery park, which is equipped with reliable devices from renowned manufacturers. This allows us to laser-cut pipes and square profiles in the following areas: 3D Laser cutting of pipes with a diameter of 20 to 210 mm and a maximum length of up to 6,500 mm (maximum pipe cutting length of 6,000 mm), 3D Laser cutting of square profiles 20 × 20 and 150 × 150 with a length of up to 6500 mm, 3D laser cutting of other tubes with a diameter not exceeding 210 mm (e.g., 150 × 20 mm). Please send your inquiry to the following e-mail address: laser@web-elektron.pl. The 3D laser cutting technology ensures perfect precision when the order concerns such materials as copper, steel, stainless steel

Request for a quoteResults for

Cutting of tubes - Import exportNumber of results

86 ProductsCountries

Company type

Category

- Cutting - steels and metals (10)

- Mechanical engineering - custom work (9)

- Laser - cutting and welding machines (8)

- Pipes and tubes - ferrous metal (4)

- Machine tools, cutting - parts and accessories (3)

- Plastics - industrial machinery and equipment (3)

- Copper and copper alloys (2)

- Extrusion, plastics - machinery (2)

- Hoses, pipes and tubes - plastic (2)

- Lifts and platform elevators, car (2)

- Pipe and tube fittings - ferrous metal (2)

- Pipes and tubes, stainless steel (2)

- Plasma cutting machines (2)

- Sawing machine tools (2)

- Steels and metals - forming and cutting (2)

- Testing equipment (2)

- Bags, plastic (1)

- Drills, pneumatic (1)

- Environmental clean-up - machines and equipment (1)

- Import-export - medical and surgical equipment (1)