- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- process control

Results for

Process control - Import export

Q-INTERLINE A/S

Denmark

The InSight Pro concept offers a modern and future-ready in-line analyser solution. We have taken all unnecessary complexity out of the product to offer a high-end solution that is easy to purchase, install and run for years. InSight Pro offers measuring devices adapted for various sample types. One or two measuring points can connect to the analyser via flexible optical fibres. > What can you achieve: - Faster start-up - Stable process - Produce closer to target - Less waste and rework - Full traceability - Energy optimisation - Predictability > The InSight Pro systems offers the customer : - A maintenance-free system - One or two measuring points - Full CIP/SIP compliance - IP65 protection for easy installation - 3-years warranty - Choice between five configurations - Built-in 24/7 surveillance - Same analyser engine used at-line - Operator-friendly software – InSightView

Request for a quote

Q-INTERLINE A/S

Denmark

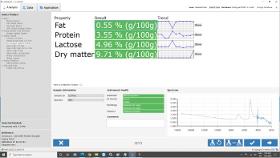

InSightView is the frontend software to monitor and control the daily operation of the InSight Pro analyser concept. InSightView offers a full overview of the measurement results and validity, running average, trend curves, etc. in a simple and efficient way. With the use of colour codes, set against fully configurable criteria, it is quick and easy to obtain information about the status of the production and the analyser with just a brief glance. InSightView is designed to be operated by process personnel with a multi-language user interface. > Software highlights: - Real-time analytical results - Built-in process stability indicator - Calibration sample relevance indicator - Link to AnalyticTrust for easy instrument surveillance and QA - Intuitive and easy to use without training - Select between multiple languages - Runs on Windows 10 pro

Request for a quote

Q-INTERLINE A/S

Denmark

This business area covers a vast range of applications and has been a natural part of our business since 1996. Whereas food products classically have a very high volume and a lower price per ton, the ingredients area is characterised by somewhat lower volume but a clearly higher price per ton. Both scenarios may greatly benefit from process optimisation, often following two different strategies. To optimise the process, a bias-free accurate insight into process dynamics and variations is needed. Many of our solutions have been developed together with customers seeking new innovative and value adding answers to well-known challenges, and our unique combination of curiosity and the skills present in our team has formed the basis for new products. Q-Interline’s analyser and project model are ideally suited to support exactly that, and we offer fast and reliable laboratory at-line units operated by process operators, as well as real-time in-line analysers.

Request for a quote

Q-INTERLINE A/S

Denmark

InfraQuant offers an easy-to-use platform to streamline QC operations and produce analytical results of high and trusted quality. We understand that the supervisor wants a highly configurable tool, whereas an operator is looking for simplicity. That is why InfraQuant has balanced both these aims and offers an advanced configuration module as well as an easy front interface to run the daily routines. The front-end Wizard guides the operator through the analysis sequence with information messages, warnings and reminders. The Wizard ensures consistent results independent of operator skills and experience. Our philosophy is to minimise the use of the mouse and work from a “next-next-next-ok” design perspective. > Software highlights: - Runs on up-to-date windows 10 - Intuitive and easy to use without training - The choice between multiple user languages - Easy link to AnalyticTrust for easy instrument surveillance and QA - Easy link to LIMS

Request for a quote

Q-INTERLINE A/S

Denmark

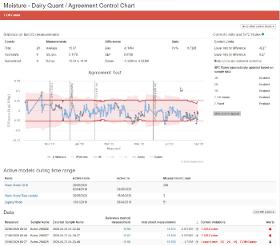

FT-NIR instruments need supervision. They must be checked and re-calibrated at regular intervals in order to maintain the precision required to sustain the business case. Some results are used in Big Data interpretations and internal data flows and the effect of lost data quality is almost certainly bad data out. In daily operation AnalyticTrust manages a customisable schedule of verification activities very much like a workflow management tool. Validation must be performed at regular intervals and reminders are sent to operators. In cases of non-compliance escalation emails are sent to management. AnalyticTrust integrates directly to instruments and computers, receiving the results of measurements and storing them in the instrument database. This allows AnalyticTrust to perform analysis of the validation results and predict instrument degradation and failure. Automatic Performance Degradation detection is used to request unscheduled instruments calibration or parts replacement.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Q-INTERLINE A/S

Denmark

The Quant, a unique state-of-the-art FT-NIR spectrometer engine, is used for everything we do! We develop, patent, and produce many different accessories to handle nearly all types of samples and materials, but the base analyser remains the same. > The Quant based system offers the customer: - One proven platform - One spectral format to handle across all applications - Same spare parts fit all analysers - Same software across all applications - Same LIMS interface for all applications - Easier operator training - Same link to AnalyticTrust surveillance & support platform - 3 years warranty - No scheduled maintenance - Lamp life on average 10 years - Internal laser lasts for the instrument lifetime - Highest spectral performance in any commercial FT spectrometer! - More stability and better accuracy - Choice between 10 accessory configurations - Intuitive multi language user software – InfraQuant

Request for a quote

Q-INTERLINE A/S

Denmark

The chemical industry uses spectroscopy as a regular tool in many forms such as UV-VIS and FT-IR. The industry adapted to the NIR and especially the FT-NIR technology in the beginning of the 90’ies and our base technology has been utilized ever since in very diverse applications. The industry is in many areas regulated by legislation demanding that release of products can only be done by the official methods, but the industry has learned to utilize the options to run in-process analysis and control the process. That is where Q-Interline and our partners can supply solutions. We offer an analyser for the laboratory as well as the process and we have extensive experience in designing and building tailor-made optical cells and probes in a wide range of materials. Having full control of the entire manufacturing process of probes, cells and optical fiber cables allows us to full-fill many demanding applications.

Request for a quoteResults for

Process control - Import exportNumber of results

8 ProductsCountries

Company type