- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dry cooler

Results for

Dry cooler - Import export

STEFANI SPA

Italy

SCIROCCO W is the new tabletype dry cooler for refrigeration, conditioning and industrial process applications.

Request for a quote

REFRA, UAB

Lithuania

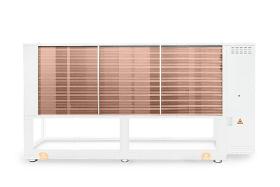

Wide capacity range dry cooler series, which can be used in waterloop systems or as a free-cooling option in chillers. This small to medium capacity product is perfect for small and medium commercial buildings and various supermarkets. Available heat capacity is up to 350 kW under nominal conditions (when ETG is 35%, Tin is 45°C, Tout is 40°C and Tamb is 35°C). Flat shaped simple construction is assembled with smooth copper tubes, aluminum or copper fins and EC/AC fan motor technology. The galvanized steel and powder coated frame can be designed in horizontal or vertical position.

Request for a quote

ERACO CHILLER & COOLING

Turkey

The ARA-T2 series air cooled chiller devices are units employing high efficient R410A cooling fluid with zero ozone thinning potential and having two scroll compressors. The device will start to run at half capacity in cases where the capacity need is low and the electricity consumption will be decreased significantly by being equipped with two compressors. Beside this, it operates at half capacity and the complete stoppage of the process is prevented in case of any defect of one of the compressors. The initial investment costs are low compared with fully independent devices. In addition, it has features like its capability to be installed rapidly and easily thanks to its high temperature sensitivity, optional colour touch-screen control panel, integrated module.

Request for a quote

FRIGOFLUID S.R.L.

Italy

The PAD-V adiabatic system is the optimal solution for increasing the efficiency of air systems, with capacities from 75 to 1,100 kW. Dry operation during cold periods: ambient air is drawn in and conveyed to the heat exchange coils (where the fluid to be cooled passes through): no water in the circuit, as during standard dry cooler operations. Energy use is also optimized by electronically modulated fan speeds based on temperatures. Adiabatic operation during hotter periods: outside air passes through the humidifier pack to be pre-cooled, before being conveyed to the finned coils and performing its cooling function: efficiency is increased. This also makes it possible to work at lower ambient temperatures.

Request for a quote

FRIGOFLUID S.R.L.

Italy

RAW/E liquid coolers (water, water/antifreeze) operate through a closed circuit, consisting of a finned coil crossed in countercurrent by ambient air. Due to the sizing of the coil, it is possible to achieve process fluid temperatures close to the temperature of the intake air. They are industrial chillers designed for fluids between 0°C up to 70°C, with external temperatures between -10°C and +50°C: cooling powers available as standard from 64 kWf up to 782 kWf, considering a 10°C difference between ambient air and supply water. “RAW” series chillers are environmentally friendly machines: the fluids used in the cooling process are simply water/antifreeze (fluid to be cooled) and ambient air (cooling fluid). In addition, the use of high quality materials allows the achievement of high efficiency values (ratio of kWf rendered in cooling to kW absorbed in power consumption).

Request for a quote

MITA COOLING TECHNOLOGIES

Italy

Drycoolers are simple and reliable equipment. Their principle of operation is based on a sensible heat exchange between air and water where: air is drawn in by fans through a finned coil, while water (or a mixture of water and glycol) flows through the tubes that make up the coil and cools when ambient air (colder cooler) laps the surface of the latter. Exchange coils, with a "V" arrangement within the cooler, consisting of copper tubes and aluminum fins. The angle between the coils, the diameter of the tubes, and the thickness and length of the fins, are sized to ensure the best heat exchange performance, for a given fluid and air flow pressure drops.

Request for a quote

MITA COOLING TECHNOLOGIES

Italy

Dry coolers are simple and reliable equipment. Their operating principle is based on a sensible heat exchange between air and water where: air is drawn in by fans through a finned coil, while water (or a mixture of water and glycol) flows through the tubes that make up the coil and cools when the (cooler) ambient air laps the surface of the latter. Fins are used to increase the overall heat exchange surface area so that the equipment can be as compact and efficient as possible.

Request for a quote

MITA COOLING TECHNOLOGIES

Italy

Ideal for water saving maintaining a high efficiency. All operations are managed by PLC with the possibility of remote management in “Industry 4.0” mode. Both HVAC and refrigeration sectors can be served.

Request for a quote

MITA COOLING TECHNOLOGIES

Italy

Ideal for water saving maintaining a high efficiency. All operations are managed by PLC with the possibility of remote management in “Industry 4.0” mode. Suitable for both industrial and HVAC fields of application. The adiabatic cooler, sometimes called adiabatic dry cooler or dry cooler with adiabatic pre-coolers, is designed to work with both air and water, with particular attention to efficiency. The external air is used to cool the liquid during dry operation and it is pre-cooled only in hot periods with wetting cycles of about 15 seconds during adiabatic operation (“adiabatic pre-cooling”).

Request for a quote

STEFANI SPA

Italy

OSTRO W is a product range designed to meet the needs of high capacity exchange in dry cooler and condenser operation for the industrial process, HVAC air conditioning and refrigeration. With the PAD or SPRAY versions the capacity increases, thanks to water injection, are very significant and guarantee a legionellafree solution.

Request for a quote

STEFANI SPA

Italy

ZONDA is the new Vtype singlerow dry cooler allow heat exchange designed for limited space availability or visibility on the roofs.

Request for a quote

FRIGOFLUID S.R.L.

Italy

Often the main critical issue for molding industries is not achieving the temperatures needed for their processes, but maintaining them over time. Hence the usefulness of temperature control units that not only send the fluids needed to do the job up to temperature, but are capable of subsequent self-tuning. This is the way FTT DC water temperature controllers operate, which wrap direct cooling to stabilize fluid grades after the desired temperature has been reached. This requires integration with a source of cooled water: a simple well or a chiller or cooling system (chiller or dry cooler). Our engineers are available to determine which cooling solution is the most effective and economical. Not only that. The management of these successive heating-cooling steps is easier when done with a touch screen: a feature with which FTT DC temperature controllers are equipped. Units in the FTT category are specially designed to condition molds.

Request for a quote

VAN WEST KOELTECHNIEK BV

Netherlands

The WWKGD30 is a compact water cooler that can easily be installed in, for example, coffee machines or the kitchen cupboard. The built-in thermostat allows you to set the desired temperature. The water cooler can be easily connected to the water supply network. The water cooler requires hardly any maintenance and always supplies refreshing cooled water.

Request for a quote

VAN WEST KOELTECHNIEK BV

Netherlands

The WWKGD24 is a compact water cooler that can easily be installed in, for example, coffee machines or a kitchen cupboard. The built-in water cooler can be easily connected to the water supply network. It requires hardly any maintenance and always supplies refreshing cooled water.

Request for a quote

KELVION HOLDING GMBH

Germany

Our customized and energy modular radiators offer a rugged and reliable design. More than 40 years of experience in manufacturing all types of radiators and dry coolers guarantee a high performance solution in various applications.

Request for a quote

REFRA, UAB

Lithuania

Wide capacity range dry cooler series, created for small to large refrigeration systems with high power demand. Complete with a double heat exchanger and single/double fan row, this product is a super effective solution, which can provide large heat capacity while being installed in limited space area. For these reasons it is a popular choice for medium to large size commercial and industrial buildings. Available heat capacity is up to 550 kW under nominal conditions (when ETG is 35%, Tin is 45°C, Tout is 40°C and Tamb is 35°C). Capacities up to 1.2 mW can be achieved by ordering a modular DV type with more heat exchangers that are tilted to the side and reduced in length. V shape construction, assembled with smooth copper tubes, aluminum or copper fins and EC/AC fan motor technology. The galvanized steel and powder coated frame can be made in various sizes.

Request for a quote

REFRA, UAB

Lithuania

High capacity range dry cooler series, perfect for large industrial refrigeration systems. 4 heat exchangers and double fan row can provide especially large heat capacity within limited placement area, making it the unit with the highest power supply per square meter. Available heat capacity ranges over 1 MW under nominal conditions (when ETG is 35%, Tin is 45°C, Tout is 40°C and Tamb is 35°C). W shaped large construction, assembled with smooth copper tubes, aluminum or copper fins and AC/EC fan motor technology. The clever frame design also allows for the installation of additional equipment under the dry cooler.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

REFRA, UAB

Lithuania

High capacity liquid-cooled chillers with the cooling power from 140 kW to 2 MW are perfectly suitable for medium to large industrial or large commercial applications. These chillers can be integrated with a dual liquid system, where the condenser uses glycol mixture and the evaporator uses water for the refrigeration process. Due to the glycol-free ability, CS chillers are ideal for particularly sensitive equipment that requires refrigeration with clean, distilled water. CS chillers are assembled on a welded open frame, equipped with maximum 4 screw compressors and shell and tube heat exchangers. Usually stored in special technical rooms and connected to secondary devices such as cooling towers or dry coolers to reject the absorbed heat to an additional fluid loop. Refra manufactures modern devices using plug-and-play ideology, making the installation and use of the devices as easy as possible.

Request for a quote

PLANER ENGINEERING&COOLING SYSTEMS

Turkey

Aircooled chiller,Watercooled chiller,Dry cooler,Evaporatif dry cooler,Hybrid chiller

Request for a quoteResults for

Dry cooler - Import exportNumber of results

20 ProductsCategory

- Dry cooling towers (5)

- Heat exchangers (3)

- Heating and air conditioning - works (3)

- Refrigeration plants and equipment, commercial and industrial (3)

- Water refrigerants (2)

- Air conditioning equipment (1)

- Condensers (1)

- Gas cooling agents (1)

- Heat pumps, industrial (1)

- Measurement and regulation equipment and instruments - temperature (1)