- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- extrusion - steel and metals

Results for

Extrusion - steel and metals - Import export

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

There are many benefits of impact extrusion. Whether combined, forward or backward extrusion, there is a high level of dimensional accuracy and the possibility to achieve a close approximation to the final shape. Offering 100 percent tightness, impact aluminum extrusion allows a high degree of transformation in a single production step, high operating speeds at low unit costs and numerous shaping and design possibilities. In addition, impact extrusion provides compact structure, a smooth surface, no soldered or welded seams and excellent stability.

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Aluminium extruded holder is available to suit 5mm 8mm & 10mm brush strip. It is available in 45 degrees, 90 degrees, and 180degrees to suit the brush strips application. Other types of holder are available on request. Bespoke products are also availablefor high end finishes and requirements. Call us to discuss your needs. Our professional & expert staff will always be able to help wherever possible.

Request for a quote

PLANSEE SE

Austria

Molybdenum-hafnium carbide (MHC) is highly temperature-resistant, has a high level of thermal conductivity, a low coefficient of thermal expansion and a high recrystallization temperature. MHC retains its shape even when used at temperatures of up to 1 550 °C. At temperatures up to 800 °C, MHC is suitable for use in die inserts. At higher temperatures, the producer recommends using MHC for full dies. The benefits to you for a long service life: — Optimum nondeformability and dimensional stability — Low tendency to crack in the case of edged profiles — High thermal stability — High thermal conductivity — Low thermal expansion — Good hot ductility — Very high recrystallization temperature Plansee supplies MHC components in disc form with or without drilled start hole.

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

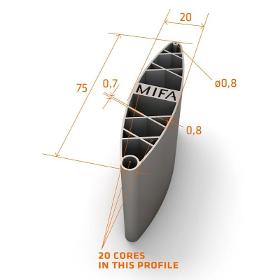

EN-755-9 and EN-12020-2 are the accepted norms for the extrusion of aluminium profiles. They allow deviations of 0.15 mm or more. Mifa ignores these norms and applies precision extrusion of 0.02 mm. We’re unique in the world! And it gives countless possibilities. Bulk production. Standardised work. Inaccurate. These are words that you’ll hear often if you ask engineers for the features of extrusion. But there is another option. Mifa’s delivery starts from 10 kg, and we offer custom-built products and precision, also for straightness, torsion, concentricity, parallelism, surface roughness and tting. Add to this the outstanding features of aluminium – post-processing is often not needed – and it becomes clear that precision extrusion would be useful for many applications. Even as a replacement of other techniques and materials.

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

Anodizing, galvanizing, passivation, painting: Mifa offers customers all possible surface treatments. A good surface treatment can protect against corrosion, reduces wear or friction, can be electrically insulating or conductive, and in many cases makes the product visually more attractive. Mifa sees surface treatment as the nishing touch that not only increases durability but also adds extra functionality to the aluminium product. The main surface treatments for aluminium that Mifa offers can be roughly divided into three categories: - Conversion layers: aluminium passivation, anodizing, and plasma electrolytic oxidation - Galvanic coatings: chemical nickel-plating, silver, gold, tin, hard chromium etc. - Organic coatings, painting, paint primers, adhesive primers CVD (Chemical Vapour Deposition), PVD (Physical Vapour Deposition), and synergistic coatings can also be applied on request.

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

Mifa has an extensive range of modern CNC-controlled machinery. Nevertheless, we prefer to use machining work as little as possible. Thanks to the combination of precision extrusion, CNC machining, and surface treatment, we can shorten the total production time for machining and improve the quality of the product. We write the software ourselves and make our own moulds for the CNC machining. Every profile is different and often demands a specific processing method, particularly if it is a visible surface. To this end, we use CAD/CAM programmes such as Solid Works, Solid Edge, and Unigraphics. We also develop the clamping tool ourselves too. The right clamping method is crucial in order to achieve the desired result. The best clamping method is dependent on factors including the dimensions and thickness of the profile and the processes to be implemented. For more text and explanations about our CNC and aluminium machining possibilities, please contact us.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

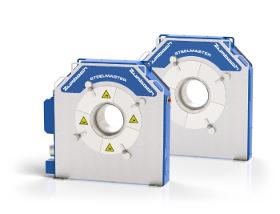

Oscillating multi-mode gauges STEELMASTER SMO from ZUMBACH are a well-proven line of precision gauges for hot rolling mills and for cold processes. They are available for various measuring ranges and in many versions in order to suit all needs. Over 400 systems are in operation worldwide. SMO gauges are mechanical simple, robust and very reliable. Outstanding Advantages • 1000 (option: 2000) measurements /s (each axis) • Latest technology – Highest accuracy • Extremely compact • 3 measuring modes at choice – Static mode shows evolution over 1 billet – Oscillating mode captures entire profile – Selective oscillation over programmable angle, shows critical dimensions, especially for non-round products • Measures rounds and non-round profiles, regardless of product twist • Computes also cross section (mm2/in.2) • Special versions for 3-roll mills incl. EPM and FPS software • Reliable, thanks to unique protection system • Uncritical guiding

Request for a quote

UMIT ALUMINIUM

Turkey

All of your aluminum products are produced in our extrusion factory, from architectural systems to all other sectors. We always meet the demands of our customers by keeping the minimum production amount limited to 500 kilos. In our electrostatic powder coating, we paint your products in the colors you want with high quality and deliver them to your address wherever you are in the world. In addition, we advertise your product by printing the company logos of our customers on the sticker and sticking them on the products. We guarantee that our prices will be the best you can find and the best service.

Request for a quote

UMIT ALUMINIUM

Turkey

All of your aluminum products are produced in our extrusion factory, from architectural systems to all other sectors. We always meet the demands of our customers by keeping the minimum production amount limited to 500 kilos. In our electrostatic powder coating, we paint your products in the colors you want with high quality and deliver them to your address wherever you are in the world. In addition, we advertise your product by printing the company logos of our customers on the sticker and sticking them on the products. We guarantee that our prices will be the best you can find and the best service.

Request for a quote

ALIPLAST ALUMINIUM EXTRUSION N.V.

Belgium

One of the extrusion presses at Aliplast Aluminium Extrusion

Request for a quote

ALIPLAST ALUMINIUM EXTRUSION N.V.

Belgium

After extrusion, the profiles can be anodized, powder coated and or machined

Request for a quote

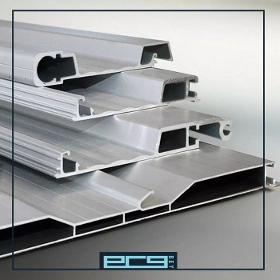

ERGBEY ALUMINIUM

Turkey

Welcome to our world of aluminum profile extrusion! We are a leading company that specializes in creating custom-made profiles to meet the unique needs of our customers. Whether it's for industrial or architectural purposes, we are here to help. Our expertise extends to creating high-quality solar profiles that cater to the increasing demand for renewable energy sources. With our state-of-the-art technology and skilled workforce, we guarantee to deliver unparalleled products and services. Contact us today to start your customized profile journey with us

Request for a quote

EREN KALIP MAKINE PLASTIK SAN. VE TIC. LTD. STI.

Turkey

We produce main and auxiliary moulds of PVC window and door systems.

Request for a quote

MODULUS METAL

Turkey

Modulus Metal has ISO certified supplier base and our partner suppliers are experienced in automotive, aerospace, agricultural, railway, and industrial machinery manufacturing for many years.

Request for a quote

OREMUS S.R.O.

Czech Rep.

Our work starts with precise and efficient material cutting using modern machines. Our Laser and plasma cutters are available for sheet metal processing of all grades. Laser Trumpf 4kW with interchangeable table 4000x2000mm cuts mild steel of max. 18mm with both oxygen or nitrogen. Plasma Omnicut/Hypertherm where portal is also fitted with an acetylene burner; table size 6500 x 2000mm, usually cuts max. thickness 100mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OTTO EICHHOFF GMBH & CO. KG

Germany

Turned parts Long turned partes, small turned parts Turned, milled and grinded parts Thread inserts in brass, steel and stainless steel Possible materials: Alloy AlCuMgPb, AlZn5,5MgCu etc. Brass CuZn39Pb3, CuZn40Pb2 etc. Stainless steel 1.4301, 1.4305, 1.4571, 1.4401, 1.4101 etc. Steel Machining steel, St52, St37, C45, etc. Special steels Titan, Hastelloy, Copper, Bronze etc. Surface treatments may be done as follows: Galvanizing, nickel, brown, hot-dip galvanizing, phosphating, anodizing, chrome plating, painting, powder coating, plasma coating, sandblasting, Tuflok coatings. All common surfaces as VDA standard are possible (zinc-nickel, zinc flake). Heat treatments such as Plasma / gas nitriding, carbonitriding, hardening, carburizing, vacuum hardening, tempering etc.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is CNC laser cutting and bending. The material can be stainless steel or aluminum.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Stainless steel gas springs function the same as their common hydraulic counterparts, but give an alternative when operating under rough conditions such as off-shore and other outdoor exposure applications. Other commons application areas for stainless steel gas spring include health care products, food industry and medical devices.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC Turning aluminum part

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

ESTIMET SP Z O.O.

Poland

Kokeneen tiimin ja nykyaikaisten koneiden ansiosta ESTIMET pystyy käyttämään lähes kaikkia arkkiin liittyvää tehtävää. Valssattujen elementtien reunat ovat taivutetut, mikä poistaa tarpeen käyttää ns. catwalkeilla. Tämä vähentää syntyvän jätteen määrää. Tyytymättömien kiintoaineiden romahtaminen voidaan suorittaa mikrojuoksuilla kierukkamaisen elementin kriittisissä osissa. Roll up -toiminnon jälkeen mikrohiukset poistetaan meiltä.

Request for a quote

ESTIMET SP Z O.O.

Poland

Böjning upp till 5000 mm x 225 ton Våra tryckbromsar har förmåga att böja upp till 5000 mm långa tryck med ett tryck på 225 ton med ett mycket rikt lager av böjverktyg som gör att du kan böja även mycket komplicerade element. Vi använder programvara för att beräkna utvecklingen från 3D-modeller. Våra maskiner är kompatibla med de flesta CAD-format. Pressbromsen är den viktigaste komponenten som krävs för att utföra plåtböjning. Det har vissa möjligheter och begränsningar. Böjverktyget (matris, slag) bestämmer också huruvida en given böjning kan göras. ESTIMET-företaget har ett mycket stort utbud av alla typer av böjverktyg. Tack vare detta kan vi inse även den mest ovanliga och krävande böjningen.

Request for a quote

ESTIMET SP Z O.O.

Poland

Bøying av plater på numerisk styrte kantpresser, opptil knekkelinjens lengde (bøyingslenge) 5000mm

Request for a quoteResults for

Extrusion - steel and metals - Import exportNumber of results

86 ProductsCountries

Category

- Steels and metals - machining (31)

- Turning - steels and metals (30)

- Milling - steels and metals (22)

- Bending - steels and metals (20)

- Extrusion - steel and metals (13)

- Welding work - steels and metal (13)

- Steels and metals - welding and brazing (10)

- Cutting - steels and metals (9)

- Steels and metals - forming and cutting (9)

- Screw cutting - steels and metals (7)

- Steel & Metal Transformation (7)

- Steel & Metals (6)

- Forming - steels and metals (3)

- Sintering - steels and metals (3)

- Grinding - steels and metals (2)

- Import-export - steels and metals (2)

- Pipes and tubes, stainless steel (2)

- Straightening - steels and metals (2)

- Boring - steels and metals (1)

- Electron beam welding - equipment (1)