- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coupling

Results for

Coupling - Import export

NORELEM FRANCE

France

Zero backlash, torsionally rigid, resiliently flexible and maintenancefree full metal coupling for transmitting angle synchronous rotary movement. The innovative slit structure makes possible a very good axial, radial and angular flexibility with low reset force. Ideal for servomotors. Assembly Recommended shaft tolerances h7. On request Hub bores D1 and D2 with separate tolerance class or range. Note Procedure for enlarging predrilled bores D1/D2 Drill the bore out using a small as possible drill or milling cutter. Use a single point tool to turn or bore the hole out to its finished size. Ensure that the coupling is securely held during the machining process and that the drill feed is not too high. The cut depth should not exceed 0.5 mm and the feed for the single point tool should also be not too high.

Request for a quote

NORELEM FRANCE

France

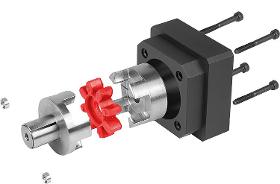

Spider polyurethane hardness Shore 98A. Hub aluminium. Conical ring carbon steel. Note This coupling series is particularly suitable for use in high speed main spindle or drill spindle drives. Before the plugin assembly, both clamping ring hubs must be fastened to the shafts with the correct tightening torque. Lightly oil the spider to ease assembly. Assembly The shaft to hub bore fit should be a transition fit. The play should be max. 0.02 mm. i.e shaft Ø 25 k6 bore Ø 25 G6. Bores smaller than D1/D2 min. are possible, however an optimal transfer of the nominal torque is no longer guaranteed. On request Hub bores D1 and D2 with separate tolerance class or range. Drawing reference 1) elastomer spider

Request for a quote

NORELEM FRANCE

France

Steel 1.0718. Stainless steel 1.4305. Version Steel black oxidised. Stainless steel bright. Note Rigid couplings transmit high torques without rotational play. They are used where there are no shaft displacements or alignment errors. Wearfree and maintenancefree. Screws secured to avoid vibration induced loosening. The maximum torque transmission can only be achieved through optimal installation and correct shaft dimensions. Maximum speed 4000 rpm.

Request for a quote

NORELEM FRANCE

France

Centre disc polyacetal. Hub aluminium. Note Clamping the hub with a grub screw is a costeffective alternative to the Oldhamtype couplings with radial clamping hub (23030). Short mounting times. The couplings can be mounted completely assembled or a plugin assembly is also possible. Take note of the tightening torque for the grub screw. To ease removal we recommend milling a flat on the shaft. Assembly The shaft to hub hole fit is a transition fit. The play should be min. 0.01 mm and max. 0.04 mm i.e. shaft Ø 6 f7 hub Ø 6 H8. Advantages robust plugin playfree short design On request Hub bores D1 and D2 with separate tolerance class or range.

Request for a quote

NORELEM FRANCE

France

D1 and D2 are customer specific e.g. 230122025; D1 = 5H7, D2 = 8H7 Note Zero backlash, torsionally rigid, resiliently flexible and maintenancefree full metal coupling for transmitting angle synchronous rotary movement. The innovative slit structure makes possible a very good axial, radial and angular flexibility with low reset force. Ideal for servomotors. Assembly Recommended shaft tolerances h7.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Keyless locking coupling with low mass and moment of inertia. Easy to connect and release – no jamming on the shaft. Perfect for zero backlash connections. Excellent concentricity and running. Suitable for keyed and keyless shafts. for shaft diameters from 5 to 35 mm for high torques minimum axial offset when mounting selfcentring Assembly Shaft and hub must be free of oil, grease and dirt. Do not lubricate keyless locking coupling. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten nut by hand and use a torque wrench to tighten to the defined tightening torque. Tolerances Shaft diameter and hub hole Form A ±0.04 mm. Form B ±0.08 mm. Surface quality Rz ≤ 16 µm.

Request for a quote

NORELEM FRANCE

France

Particularly compact selfcentring keyless locking coupling without axial offset. for shaft diameters from 8 to 85 mm for medium torques suitable for hubs with low wall thickness no axial offset selfcentring Assembly Lightly oil keyless locking coupling on the tapered faces and contact points of the shaft and hub. Do not use MoS2 or grease. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten screws crosswise in several increments to the defined tightening torque. Dismantling Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens. Tolerances Shaft Recommended tolerance h8. Surface quality Rz ≤ 16 µm. Hub Recommended tolerance H8. Surface quality Rz ≤ 16 µm.

Request for a quote

NORELEM FRANCE

France

Universal joints with plain bearing can be swivelled by 45°. Max. transferable torque (Nm) at 150 rpm, operation angle α < 5°. * Bore depth is less than by DIN 808.

Request for a quote

NORELEM FRANCE

France

Steel C35Pb. Gunmetal Rg7. Plastic PA6.6 with MoS2). ISO trapezoidal thread based on DIN 103. Steel nuts for adjustments during manual operation and as fastening nuts. Not advised for use with motorised drives due to the steelsteel material combination. Gunmetal nuts for motion drives with low and medium speed. By insufficient lubrication, gunmetal trapezoidal thread nuts on steel spindles have good dryrunning properties. Plastic nuts for lownoise motion drives. Good dryrunning properties. Tolerance class 7H.

Request for a quote

NORELEM FRANCE

France

Shrink disc to connect a hollow hub to a shaft. They are mounted on the OD of the hub and generate pressure on the hub wall by reducing the ID with wedgeformed rings, creating a press fit between the hub and shaft. They are suitable for static, dynamic and shock loads. for extremely high torques no axial shaft/hub offset when assembling selfcentring The version 23380014072 has high tensile ISO 4762 screws. Assembly Remove existing transportation locks. Clean and lightly oil shaft, internal and external hub diameters. Do not use MoS2 or grease. Slide shrink disc onto hub. Then slide unit (shrink disc/hub) onto shaft and position correctly. Gently tighten clamping screws one after the other by hand. Then use a torque wrench to tighten the clamping screws crosswise in several increments to the defined tightening torque MS. 1st increment approx. 33% MS 2nd increment approx. 66% MS

Request for a quote

NORELEM FRANCE

France

Base and rotary table aluminium alloy. Hollow shaft stainless steel. Preloaded worm gear steel. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Rotary positioning stages for motorised adjustment and positioning tasks. The preloaded worm gear runs virtually playfree. The bearing of the worm shaft offers maximum radial rotational accuracy. Cables can be routed through the large bore in the hollow shaft. The adjustable positioning ring is used to determine the rotational reference point to the position of the assembled part. Proximity switches can be mounted with the optionally available sensor holder (21094). The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

NORELEM FRANCE

France

Elastomer spider polyurethane Shore 98A. Coupling housing and clamping hub, aluminium. Expanding mandrel steel. Screws steel. Centring rings 1.4301 stainless steel. Version Coupling housing black anodised. Note The motor adapter set with elastomer dog coupling system (elastomer coupling with expanding mandrel) provides a simple and costeffective solution for connecting electric motors. Advantages of the elastomer dog coupling Hub with expanding mandrel can be mounted axially Playfree with vibration absorption Excellent retaining force Excellent concentric accuracy Short design Easy to assemble Can be mounted axially on spigot side Electrical insulation Nominal torque up to 30 Nm On request Larger hub bore D. Higher nominal torque.

Request for a quoteResults for

Coupling - Import exportNumber of results

13 ProductsCompany type