- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- joints

Results for

Joints - Import export

NORELEM FRANCE

France

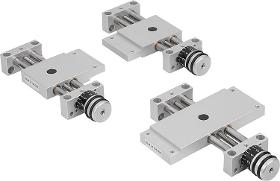

Clamping joints are used to clamp round cross sections (bars, tubes, etc.) and are infinitely adjustable. The simple design together with the adjustable clamping lever permits rapid clamping.

Request for a quote

NORELEM FRANCE

France

Stainless steel 1.4305. Version: Bright

Request for a quote

NORELEM FRANCE

France

Universal joints with plain bearing can be swivelled by 45°. Max. transferable torque (Nm) at 150 rpm, operation angle α < 5°. * Bore depth is less than by DIN 808.

Request for a quote

NORELEM FRANCE

France

Steel. Version: Ball thrust pins trivalent passivated. Ball seat and nuts electro zinc-plated. Note: Axial joint suitable for taking up tractive forces. The ball's movement can be controlled or fully locked in position using the clamping nut.

Request for a quote

NORELEM FRANCE

France

Steel or 1.4305 stainless steel Version: Trivalent passivated. Stainless steel version bright. Note: LH thread refers to dimension D2.

Request for a quote

NORELEM FRANCE

France

Steel 1.0718 or stainless steel 1.4305. Version: Steel electro zinc-plated. Stainless steel bright.

Request for a quote

NORELEM FRANCE

France

Clevis and pin, steel 1.7225 Version: Electro zinc-plated. Note: These clevises were developed as accessories for rod ends. The clevis opening size C was chosen to accept rod end joints. Suitable for rod ends 27625, 27626, 27627 and 27628.

Request for a quote

NORELEM FRANCE

France

Clamping joint high-tensile aluminium. Hinge pin, support plate and stop bar, steel. Version: Clamping joint anodised blue and black. Hinge pins, support plate and stop bar black oxidised. Note: The 5D-swivelling stop serves, among other things, as a versatile instrument for positioning on machining tools or for assembly work. It is infinitely adjustable, quickly and flexibly in 5 axes. Supplied complete with M8x12 T-slot nut and hex key. On request: Connecting element for combining several 5D-swivelling stops.

Request for a quote

NORELEM FRANCE

France

Highperformance polymer iglidur® G, iglidur® J or iglidur® X. Version iglidur® G grey; iglidur® J yellow; iglidur® X black Note Plastic highperformance polymer plain bearings. – maintenancefree – lubricantfree – corrosionresistant – resistant to dirt – high dimensional precision – high pressure resistance – good heat dissipation – very low creep tendencies – high mechanical damping – resistant to UV radiation. Assembly The bearings are designed for press fits in H7 bores. After pressing in, the ID of the bearing will be diameter D with the relative tolerance. The bearings are suitable for shafts with h tolerance (recommended min. h9).

Request for a quote

NORELEM FRANCE

France

Selflubricating. Hardness 190220 HB. Note The guide bushes are radially and axially applicable. The bearing elements are maintenancefree and wearresistant. The graphite inserts provide lifelong lubrication. Preferably for travel speeds < 0.5 m/s. (Additional lubrication is recommended for extreme loading with a higher travel speeds). Temperature range Temporary temperature peaks up to ca. 200°C. Tolerances The bore for the bearings should correspond to ISO tolerance H7. The tolerance h6 to h7 is recommended for the shaft.

Request for a quote

NORELEM FRANCE

France

Exceptionally wearresistant Dimensionally stable even at high temperatures Electrically insulating Frequency neutral

Request for a quote

NORELEM FRANCE

France

Housing igumid® G. Swivel ball iglidur® W300 Note The ability to pivot allows pillow block bearings to compensate for misalignment and possible shaft deflection. They are easy to install and suitable for the accomodation of rotating, oscillating and linear movements. igubal® pillow block bearings are maintenance free and conceived for dry running condition. Assembly These pillow block bearings are designed for mounting with 2 screws. The ID tolerance is E10. The matching shaft should have a tolerance of h6 to h9.

Request for a quote

NORELEM FRANCE

France

Steel 1.1213. Stainless steel 1.4034. Stainless steel 1.4112. Version Steel, ground. Steel, ground and hardchromed, chrome coating 5 10 µm. Stainless steel, ground. The precision steel shafts are generally inductively surface hardened. Note The surface value obtained during the inductive hardening process guarantees high surface wear resistance. Suitable for shaft supports 21565. On request Lengths up to a max. 4000 mm. Accessory Shaft supports 21565. Drawing reference 1) chamfered

Request for a quote

NORELEM FRANCE

France

Shaft support with bore for easy and secure clamping and fastening the guide shafts. Precision guide shafts 21595. Fastening screws 07160 or 07161.

Request for a quote

NORELEM FRANCE

France

Extruded section, aluminium EN AW6060. Version Hard anodised aluminium, 50 µm. Hardness 500 HV. Note The aluminium guide rail has good thermal conductivity and importantly heats only at continuously very high speeds. ** lengths L2 = 20 mm * and L = 500 mm included L2 and L only available in full mm.

Request for a quote

NORELEM FRANCE

France

Sliding carriage Base structure in extruded section, aluminium EN AW6060. Sliding elements Maintenance free plain bearing iglidur® J. Version Eloxalcoated E6/EV1. Black thermoplastic Note With a low rate of inerita, high accelerations and short term extreme speeds up to 30 m/s are possible. DryLin® T linear glide guides are resistant to dirt and corrosion and are adjustable, maintenancefree and quiet. Application temperature max. 80 °C. As no lubricants are used they are recommended for use in food, medical, and clean room technologies. Manual clamping was developed for simple functions. Polymer under constant pressure has a tendency to creep which causes a decrease in clamping force over time (up to 70%), which means that no safetyrelevant parts should be clamped. Suitable guide rails see 21200. Drawing reference 1) manual clamping

Request for a quote

NORELEM FRANCE

France

Base and rotary table aluminium alloy. Hollow shaft stainless steel. Preloaded worm gear steel. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Rotary positioning stages for motorised adjustment and positioning tasks. The preloaded worm gear runs virtually playfree. The bearing of the worm shaft offers maximum radial rotational accuracy. Cables can be routed through the large bore in the hollow shaft. The adjustable positioning ring is used to determine the rotational reference point to the position of the assembled part. Proximity switches can be mounted with the optionally available sensor holder (21094). The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Body and rotary table Al alloy, anodised. Spindle steel, casehardened. Spindle bearing maintenancefree. Position indicator plastic. Version Radial play of rotation axis < 0.015 mm. Axial play of rotation axis < 0.02 mm. Repeat accuracy < 0.05°. Spindle selflocking. Note 360° adjustment with no end stop. The position indicator displays in 0.1° increments clockwise. The angle of rotation is indicated directly on the large LCD display. The rotary stage rotates anticlockwise. Reset, chain dimension and offset settings can be made via the keypad. 2 years battery life. The battery is quick and easy to replace. The mounting position of the position indicator is set in 4 positions using one screw. Transmission ratio 211611008 = 501 211611012 = 551 211611025 = 501 The modular design enables the rotary stage to be easily combined with other items of the same size. Drawing reference Assembly position of position indicator a) top (standard) b) right c) bottom

Request for a quote

NORELEM FRANCE

France

Body and rotary table Al alloy, anodised. Spindle steel, casehardened. Spindle bearing maintenancefree. Version Radial play of rotation axis < 0.015 mm. Axial play of rotation axis < 0.02 mm. Repeat accuracy < 0.05°. Spindle selflocking. Note 360° adjustment, no end stop. Scale graduation is 10 increments. Transmission ratio 2116008 = 501 2116012 = 551 2116025 = 501 The rotary stage can be easily combined with other modules of the same size. Drawing reference All counterbores to DIN 74Bm (D6)

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy, anodised. Guide columns stainless steel, ground. Spindle stainless steel, rolled thread. Guide bearing maintenancefree. Version Radial play on guide < 0.02 mm. No axial backlash. Spindle selflocking, with additional lock. Note The almost playfree guides and absolutely playfree spindle allow for adjustment without the need to loosen or clamp the spindle. The scale graduation is in 5 or 10 increments; 1 increment corresponds to 0.1 mm of travel. The cross stage can be easily combined with positioning stages, vertical stages and other accessories of respective size by the modular principle.

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy, anodised. Guide columns stainless steel, ground. Spindle stainless steel, rolled thread. Guide bearing maintenancefree. Position indicator plastic. Version Radial play on guide < 0.02 mm. No axial backlash. Spindle selflocking, with additional lock. Note Due to the practically playfree guides and absolutely playfree spindle, loosening or clamping of the spindle is not required during adjustments. Digital position indicators with 0.1 mm display accuracy, digits increase with right rotation. The display value of the position indicator can be adjusted by turning the carrier ring. The mounted position of the position indicator can be set in 4 positions with a screw. Within the respective sizes, the positioning stages can be easily combined using the modular principle. Drawing reference Assembly position of position indicator a) top (standard) b) right c) bottom d) left

Request for a quote

NORELEM FRANCE

France

These precision slideways with roller bearings are used in machine and fixture construction, metrology, optical instruments and precision mechanics. The scale division on the micrometer dial is 0.02 mm. The stated permissible load values (F) are designed for a service life of 1 million travel cycles. The torque values apply only to centred slides. An additional centring hole is located at holes D2 and D3 on the top of the slide. Other connecting elements can be precisely mounted on the slide in combination with our centring rings 20240. F = permissible loading for dynamic and static loads. TI E/E1 = number of fastening holes E/E1/M inside. TA E/E1 = number of fastening holes E/E1/M outside. TI E4 = number of fastening holes E4/D1 inside. TA E2 = number of fastening holes E2/D1 outside.

Request for a quote

NORELEM FRANCE

France

These precise slideways are used in e.g. machine, fixture and metrology equipment construction as well as in the optical and precision engineering industries. The central set screw M1 can be replaced by a clamping lever 06460. The stated permissible load values (F) are designed for dynamic loads with a service life of 1 million travel cycles. For static loads, 10 times the table value F is permitted. The torque values apply only to centred slides. An additional centring hole is located at holes D2 and D3 on the top of the slide. Other connecting elements can be precisely mounted on the slide in combination with our centring rings 20240. TI E = number of fastening holes E/M inside. TA E = number of fastening holes E/M outside. TI E1 = number of fastening holes E1/D1 inside. TA E1 = number of fastening holes E1/D1 outside.

Request for a quote

NORELEM FRANCE

France

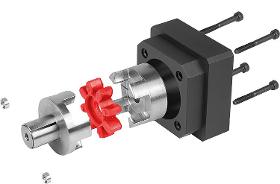

Elastomer spider polyurethane Shore 98A. Coupling housing and clamping hub, aluminium. Expanding mandrel steel. Screws steel. Centring rings 1.4301 stainless steel. Version Coupling housing black anodised. Note The motor adapter set with elastomer dog coupling system (elastomer coupling with expanding mandrel) provides a simple and costeffective solution for connecting electric motors. Advantages of the elastomer dog coupling Hub with expanding mandrel can be mounted axially Playfree with vibration absorption Excellent retaining force Excellent concentric accuracy Short design Easy to assemble Can be mounted axially on spigot side Electrical insulation Nominal torque up to 30 Nm On request Larger hub bore D. Higher nominal torque.

Request for a quote

NORELEM FRANCE

France

Body, extruded aluminium section. Bearing housing and slide, aluminium. Profile guide rail and guide carriage, steel. Toothed belt, polyurethane with steel cord reinforcement. Version Body natural colour anodised Bearing housing and slide, black anodised. Tracks of the profile guide rail, inductively hardened and ground. Note Compact and flexible linear actuators with toothed belt drive. The body consists of a selfsupporting aluminium extruded section with integrated profile guide rail. This rail system is able to absorb highest forces from all directions, is lowwear, and is optimised for moving large masses. Slots are located on the outer sides of the aluminium profile, ensuring easy, reliable assembly and enabling accessories mounted. Proximity switches can be positioned and fastened in the upper Tslot. The aluminium profile is fully compatible with our standard I series profiles.

Request for a quote

NORELEM FRANCE

France

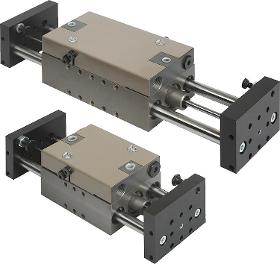

Body and flange plate EN AW5754. Guide shafts steel Version Body, hardcoated Flange plates, anodised. Guide shaft, hardened. Note Maintenancefree pneumatic linear modules with two precision steel shafts and ball guide bushing with wipers. Double acting cylinder drive. All fastening threads have threaded inserts. The as accessory available shock absorbers and proximity switches can be integrated (no protruding edges). Positive fit construction for hundred per cent reproducibility. Combinations in all sizes and stroke variants are feasible without adapter plates. Repeat accuracies of ±0.01 mm are possible. Specified loads apply by centred carriages. On request Available with locking cartridge as stroke deviation safeguard. Accessory See table for shock absorber, proximitiy switch and plug connector.

Request for a quote

NORELEM FRANCE

France

These precision dovetail slides find use in e.g. machine and fixture construction, metrology, optical instruments and fine mechanics. The stated permissible load rating (F) is for static loads. The torque values only apply for centred carriages. TI = number of fastening holes E1/E2/MI inside. TA = number of fastening holes E/E1/MA outside. TM = number of centring holes D1 inside. TN = number of centring holes D1 outside. Advantages An additional centring hole is located at all tapped holes. Other connecting elements can be precisely mounted on the slide in combination with our centring rings 20240. Quick and retrofit combination in the X, Y and Z axes.

Request for a quote

NORELEM FRANCE

France

Profile guide rails can be screwed on from above. The profile guide rails are available in four sizes and one or more carriages can be assembled on them. 4row versions with round arch profile. The tracks of the profile guide rails are set below an angle of 45° and thus can carry loads from all directions. The profile guide rails correspond to the market standard and can replace linear guides of the same design by other manufacturers. On request Lengths up to a max. 3960 mm.

Request for a quote

NORELEM FRANCE

France

Body carbon steel. Balls roller bearing steel. Diverters plastic. Standard guide carriage with recirculating ball guidance precision N not preloaded (Z0). With doublesided end seal. 4row versions with round arch profile. The profile guide rail tracks are arranged at 45° and can accept loads from all directions. High dynamic values v = 5 m/s. Applicable temperature in continuous use max. 80 °C. On request Various precision and preload classes. Drawing reference 1) ground ref. edge

Request for a quoteResults for

Joints - Import exportNumber of results

36 ProductsCountries

Company type