- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- silver-plating metals

Results for

Silver-plating metals - Import export

DELTAFLUID

France

Suitable for large flow rates with low permanent pressure dropSolder (BW) or flanged connection Material: Standard: carbon steel, stainless steel, others according to your application. Fluid: liquid, gas, steam. Diameter of pipes: from 65 to 500 mm.

Request for a quote

DELTAFLUID

France

Suitable for large flows with high speedsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. or solder connection Material: Standard: carbon steel, stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Suitable for large steam flowsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation or solder connection (BW) Material: Standard: carbon steel, stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

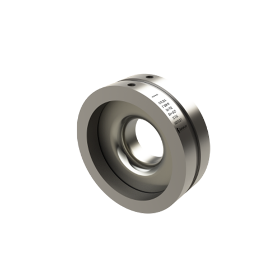

Suitable for small diameters and / or low permanent pressure dropMaterial: Standard: carbon steel, stainless steel, others according to your application. Fluid: liquid, gas, steam. Diameter of pipes: from 50 to 250 mm.

Request for a quote

DELTAFLUID

France

For a better precisionSolder (BW) or flanged connection Material: Standard: carbon steel, stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Orifices: dimensioned according to the fluid, the pressure drop or the flow to be achieved going through the restriction. Plate thickness: calculated taking into account the pressure drop generated by the plate and the diameter of the pipework in order to avoid a deformation of the plate. For more details, see our Frequently Asked Questions. Noise: the number of orifices is determined according to the level of noise not to be exceeded. The maximum noise level depends on the operating conditions: limited to 85 dB(A) by the regulatory body for an average daily exposure in continuous operation. Intermittent or emergency operation - acceptable upper values (see corresponding regulations). If the noise level is still too high, it is possible to switch to a multi-stage restriction orifice. Cavitation: the cavitation level is checked for each plate and the orifices are calculated to avoid cavitation. For more information on cavitation, see our Frequently Asked Questions.

Request for a quote

DELTAFLUID

France

Orifice diameter: dimensioned according to the fluid, to the pressure drop to be achieved and to the flow going through the restriction. Plate thickness: calculated taking into account the pressure drop generated by the plate and the diameter of the pipework to prevent plate deformation. See more details in our Frequently Asked Questions. Noise: control of the estimated noise level at 1 m. In case of high noise level, refer to the multi-hole plate. Cavitation: The cavitation level is checked for each plate. In the presence of cavitation, a multi-stage restriction orifice alternative may be proposed depending on the operating conditions of the restriction. For more information on cavitation, see our Frequently Asked Questions. Critical flow or choked flow: if the fluid reaches its maximum speed when passing the restriction, its flow can not increase. A multistage solution can be proposed depending on the operating conditions of the restriction. For more information on critical flow

Request for a quote

DELTAFLUID

France

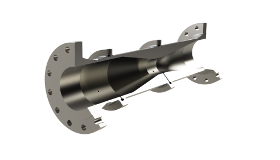

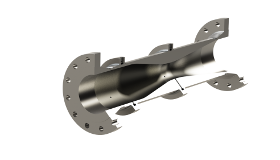

The venturi tube has a convergent inlet, a throat and a divergent outlet. It is a differential pressure flow meter well known to create a low permanent pressure drop; thus, it is suitable for measuring, for example, a low pressure flow rate. More over, it requires short upstream and downstream straight lengths. There are different types of venturi tubes : the machined venturi made from a solid round for small size parts, the rolled welded venturi made from sheet metal for larger pieces up to 1200 mm diameter and the venturi "as cast" allowing a better accuracy up to 800 mm diameter.

Request for a quote

DELTAFLUID

France

Suitable for large diameters and / or low permanent pressure dropMaterial: Standard: carbon steel, stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

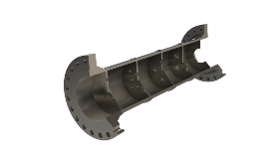

Plate mounting: plates mounted in serie - optimized plate spacing for each unit from 1D to 5D (D, pipe internal diameter). Number of plates: calculation of the number of stages optimized according to the specifications of the application, each plate making it possible to reduce the maximum pressure while avoiding cavitation and critical flow phenomena. For more details, see our Frequently Asked Questions. Noise: check of the noise level of the complete unit estimated at 1 m. Multi-holes plates reduce the noise level per stage. Solutions of external envelopes can be recommended if the noise remains too high (consult us). Thermodynamics: the thermodynamic properties of the fluid are taken into account for the calculation of each stage: change of state, temperature, composition and density of the mixture, viscosity, compressibility factor. 3D simulation: possibility of a numerical simulation to complete the analytical calculations.

Request for a quote

DELTAFLUID

France

The sonic state of the nozzle means that the flow reaches the speed of sound when going through the throat. Under these conditions, the flow rate depends mainly on the upstream pressure and the fluid temperature. This makes it possible to deliver a stable and perfectly known flow, independent of the downstream pressure conditions of the nozzle. This nozzle is thus used to provide a standard flow value when it comes to calibrating another type of flow meter.

Request for a quote

DELTAFLUID

France

The nozzle has a radiated input and is therefore suitable for fluids flowing at high speed. Unlike an orifice plate whose edge could be damaged, the ISA 1932 nozzle and the long radius nozzle according to the names of the standard are quite suitable for these applications. For corrosive or aggressive fluids, the surface in contact with the fluid can be covered with a special coating to improve their lifetime.

Request for a quote

DELTAFLUID

France

Economical solution thanks to the reduction of upstream and downstream straight lengthsStandard: Element designed on the basis of ISO 5167-1 & ISO 5167-2 or ASME FC-3M. Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application

Request for a quote

DELTAFLUID

France

Recommended for dirty, charged or diphasic fluidsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Recommended orifice plate for dirty, charged or two-phase fluidsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Recommended for viscous fluidsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Recommended for low flow rates and / or viscous fluidsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DELTAFLUID

France

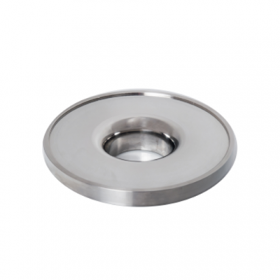

Orifice plates or diaphragms are the most commonly used primary elements for differential pressure flow measurement. They allow measurement over a wide range of flow rates and for a wide range of pipe diameters. There are several types: the sharp-edge orifice plate, the best known, the other concentric plates with conical inlet and quarter circle plate for the measurement of low flows or viscous fluids and the eccentric plate or segmental plate for the measuring dirty or impure fluids. Finally, the multi-hole / conditioning orifice plate allows a measure of quality while providing a minimum footprint. Inserted within a circular pipe, they create an obstacle, increase the speed of the fluid and generate a pressure difference between upstream and downstream of the restriction. This differential pressure measurement is proprotional to the flow rate value.

Request for a quote

DELTAFLUID

France

A spectacle blind consists of a spade and a spacer which are manufactured for the purpose of installation in one piece. It is used as a safety device to isolate a particular section of pipe or equipment when this section or this equipment is to be inspected or decommissioned. It is different from a valve in the sense that the obturator is considered an isolation device. Depending on the size and class of flanges, it will be more suitable to offer two separate components (spade and spacer) instead of a spectacle blind to limit weight and avoid handling heavy parts.

Request for a quoteResults for

Silver-plating metals - Import exportNumber of results

20 ProductsCountries

Company type