- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas mixing

Results for

Gas mixing - Import export

LEMVIG GAS DISTRIBUTION A/S

Denmark

R404A refrigerant gas is a kind of environment protective refrigerant, As the long-term substitute for R-twenty-two and R502,It is used mainly in refrigeranting systems of low & moderate temperature.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The RCV Plus™ Gas Mixing System is a combination of flow meters specifically designed to monitor and control the ratio of two gases. It consists of an RCV Plus™ and a FLO-TRONIC Plus™. The RCV Plus™ utilizes a micro-processor that continuously compares a preset ratio to the real-time ratio of the two gas flows, as measured by the FLO-TRONIC Plus™, and the ratio control valve itself. Using a stepper motor, the RCV Plus™ continuously adjusts the flow metering needle-valve to precisely maintain the preset gas ratio. The real-time ratio is continuously displayed on the LCD screen of the RCV Plus™. Included in the RCV Plus™ is an optional input for the addition of a trim gas, which is frequently used for process control. Trim gas addition is additive to the ratio. When trim gas is used, the continuously displayed real-time ratio then includes the trim gas addition.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

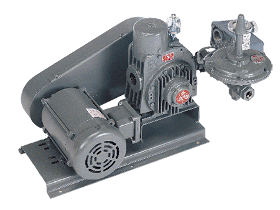

Gas Mixing Panels include the Waukee brand rotary vane compressors, air and gas Flo-Meters, and either a mechanical carburetor or RatioProver for precise ratio control. Panels are available with additive trim gas or air Flo-Meters. FEATURES: • Available with Lubed Vanes (includes a set of Phenolic Vanes and an Auto Lubricating System) or Non-Lubed Vanes (includes a set of Long Life Composite Vanes) • Available with outlet pressures ranging from 0.5-5.0psig. For higher pressures, consult UPC. • Two options available for ratio control: Standard Carburetor, RatioProver • Available with output capacities ranging from 200-12,000CFH • Available with Built-in Unloader for pressures between 0.5-2.5psig or with Bypass Relief Regulator for pressure lower than 0.5psig or higher than 2.5psig • Available with Standard turndown of 2:1 or 10:1 when used with a Compressor Pressure Controller • Includes Gas and Air Flo-Meters and Air Filter • Available with Trim Gas or Air Flo-Meters

Request for a quote

GOLF COSMETICS

Turkey

Golf Premium Butane Propane Mix Gas Catridge 227 gr. has an automatic ignition system. Thanks to its light and modern useful design structure, it can be easily carried and used. It has an ergonomic design according to the structure of the hand. It ensures a convenient use in workshops and home applications.

Request for a quote

PEMAT S.C.

Poland

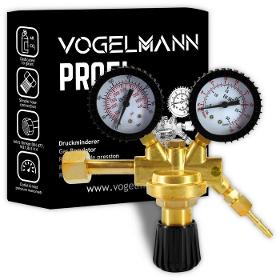

VOGELMANN PROFI - ARGON / CO2 GAS REGULATOR PROFI The universal VOGELMANN gas regulator allows you to reduce the pressure of gases taken from the cylinder to the required operating pressure.It allows to obtain the pressure automatically at the possible constant level, regardless of changes in inlet pressure. APPLICATION Single-stage reducer most often used in welding during MIG welding or TIG welding machines that require a gas shield. TWO MANOMETERSIt is equipped with two manometers - the first shows the pressure in the cylinder, the second shows gas flow per minute. GAS TYPE It is designed for technical gases such as argon (Ar), carbon dioxide (CO2) and MIX of these gases (Ar / CO2), connection: 6,3mm. UNIVERSAL The gas regulator can be connected to any standard cylinder with a W21.8 x 1/14 thread TECHNICAL DATA Gas type: CO2, Ar, MIX Inlet thread: W21.8x1 / 14 Nut thread at outlet: G 1/4 Outlet connection: ø6,3mm Inlet pressure: 185bar Outlet pressure: 0,5-10bar Throughput: 15 m³/h

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

R600 refrigerant fluid doesn't degrade or damage the compressor and other parts of condensing unit or refrigeration unit Because it has no impurities substance.The overall physical properties are also very standard. R600a refrigerant has 58.1 molecular weight. -11.7 °C ocilirg temperature. 135°C critical temperature, and 0 ®C of glide temperature.The possibility of r600a refrigerant gas mixing with oil is very low as there is outstanding adaptability with oil and lubricant.

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

MAPP Gas & Hard Torch SetThis series of portable welding gun is suitable for red welding joints Between various non-ferrous metals, and for melting welding between similar non-ferrous metals with low melting point (such as aluminum + aluminum, brass + brass jcintsi; for rod welding between ferrous metals, and welding joints composed of ferrous metals and non-ferrous metals, selecting appropriate rod materials and flux can also obtain good rod welding joints. Commodity characteristics: 1. Safe, convenient, professional and concise. 2.The combustion temperature of.HT MAPP GAS can reach above 1250 C without oxygen and combustion. 3.HT MAPP CAS is a patent formula gas for mixed gas. 4. Diameter 75mm. high 267mm for single hand welding, easy to carry. S.Scientific mixing ratio, good flame characteristics, so as to ensure the welding effect and shorten the working time. 6. Under normal working conditions, it can achieve continuous combustion time of 2 hours and 30 minutes.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Despite the increasing level of digitalization, an ever-increasing demand for paper and pulp products can be observed. However, a shift is taking place from print paper qualities to packaging paper and cardboard. The wide range of paper products requires a variety of production processes. These include mechanical and chemical processes which, depending on the form and variant, produce different pulp qualities. Stirring and mixing are essential unit processes in all types of paper and pulp production. Mixing tasks range from liquid/liquid or gas/solid/liquid mixtures, through mixing of complex liquids, and include mixing of chemically reactive components. Improving and optimizing mixing processes in the paper and pulp industry can lead to end product improvements; such as increased strength, improved luster, or significant energy or chemical savings.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Large industrial plants often vent significant quantities of low pressure steam to the atmosphere, wasting energy, water, and watertreatment chemicals. Recovery of the latent heat content of lowpressure steam reduces the boiler load, resulting in energy and fuel cost savings. Lowpressure steam's potential uses include driving evaporation and distillation processes, producing hot water, space heating, producing a vacuum, or chilling water. If the steam pressure is too low for the intended application, a steam jet thermocompressor can boost the pressure and temperature to the required level. Operating Principles - Thermocompressors and ejectors operate on the same thermodynamic and physical principle energy contained in high pressure steam can be transferred to a lower pressure vapor or gas to produce a mixed discharge stream of intermediate pressure.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EUROPEM

Belgium

Air assisted flares enable the smokeless combustion of low pressure waste gases. Air (or Gas) assisted flares can be used when no steam is available on site. Air assisted flares use forced draft Air or Gas to create turbulence ensuring that sufficient primary combustion air is supplied to the flame. The amount of air and hence the size of the tip and riser depend on the degree of smokeless operation required and the maximum flow for smokeless operation. Key features Proprietary design to maximize the mixing of waste gas and air streams and to create turbulence in the combustion zone. Variable speed fans, to supply the optimal amount of Air (Gas) Use of wind deflectors if required, to prevent flame impingement Flame holders around the periphery of the flare tip to ensure stable operation. Use of high grade alloys to enhance lifetime of the flare tip. The use of combustion/mixing air to cool the flare tip and thus enhance its lifetime Key advantages Smokeless operation under a wide range of operating conditions Smokeless flaring of high molecular weight gases Air cooling of the flare tip, resulting in longer lifetime and lower operation and maintenance costs Reduced radiant heat for a given capacity Applications Upstream oil & gas sector Chemical and petrochemical industries including refineries Tank farms and terminals Pipeline transport LNG and NG terminals and compressor stations

Request for a quote

EUROPEM

Belgium

The Tulip Vortex burner was developed specifically for (temperature controlled) combustors for the treatment of lean waste gases and vapours. It employs the same design philosophy as the Ultra-low NOx Tulip Vortex burners but is designed for the combustion of lean waste gases, whilst minimizing support fuel requirements. The burner creates an intense gas recirculation zone near the burner to ensure that waste gas, flue gas and combustion air are mixed. The resulting moderate flame temperature minimizes NOx formation. The homogeneous temperature profile and swirl result in complete oxidation and low CO emissions.

Request for a quote

NOVA WERKE AG - NOVA SWISS

Switzerland

Advanced Nova Swiss technology allows high-precision gas mixing under controlled pressure. The servo motor ensures state-of-the-art pressure regulation that is optimal for the respective application. This results in maximum precision for the injection process and ensures exact gas metering at the required pressure. Benefits : High flow rates Maximum pressure precision Low maintenance costs No daily re-adjustment required Faster start-up after interruptions. Thereby less waste during the start-up process. No compressed air supply required. Contamination-free gases thanks to diaphragm technology. The Nova Swiss gas injection unit does not require compressed air, as it is the case with pneumatic amplifiers. The integrated lubrication unit allows the system to be operated at very low speed, which in turn enables the dimensioning of extremely small quantities.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Mixor™ is a precision compressor-carburetor device which accurately mixes gas and air in any selected ratio, and compresses it for use with endothermic cracking, or exothermic cracking generators, or as a source of pre-mixed gas and air for torch brazing, flame heat treating, or sort metal melting.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The ExoFlex™ line of exothermic gas generators is designed to generate lean or rich exothermic gas. The generator includes automatic output turndown to 20% of the generator capacity with little loss of efficiency using the patented, maintenance-free ExoInjector™ gas mixing system. Thanks to a patented fuel injection technology that utilizes electronic flow measurement and precise ratio control, ExoFlex™ consistently provides the ideal mixture for high quality gas production. Another innovative design feature is the trim control input with programmable control range for precise generator control, which also eliminates the need for extra meters or valves. The ExoInjector™ easily replaces existing carburetor/pump designs for a significant reduction in process costs.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The EndoInjector™ is a precise gas mixing / control system for endothermic gas generators. It incorporates a patented fuel injection design that utilizes electronic flow measurement and precise ratio control to consistently provide the ideal gas mixture for high quality endo gas generation. The fuel injection design automatically delivers gas mixture on demand, providing only as much endothermic gas as furnaces require to reduce operating costs and eliminate gas waste. EndoInjector™ typically pays for itself in less than 1 year. The ExoInjector™ is designed specifically for exothermic gas generators. While similar in concept, the ExoInjector™ differs from the EndoInjector™ in that it comes in modified mechanical versions to accommodate pre-mix or nozzle-mix burners with a custom HMI software that allows for predefined ratio set points for burner ignition, rich exo, and lean exothermic gas. The system can be modified to provide hydrogen content control and water vapor monitoring.

Request for a quote

HILGENBERG GMBH

Germany

This compact micro torch is ideally suited for melting the ends of sample tubes precisely and safely. As a very small flame can be adjusted, it is possible to melt the capillary precisely at a defined point without excessively heating the remaining capillary, as is the case with standard torches. The torch is operated with a hydrogen/oxygen or a propane/oxygen mixture, both of which provide a very hot flame that even permits quartz glass to be processed. This torch is an extremely versatile tool with which practically all types of glass can be processed – from simple flaming to highly complex tasks. Features of the micro torch Fine, concentrated needle-point flame High heating capacity Mixed-gas operation Two separate needle valves Complete with fine nozzles Torch length >130 mm (without nozzle) Operating principle The torch consists of a gas mixing chamber and two gas inlets, which are also suitable for aggressive media such as hydrogen and oxygen. Two needle valves at the...

Request for a quote

NAMSAN METAL COMPANY

Turkey

• 3 Gas Burners(LPG/NG) + 1 Hotplate • Blue Flame • Low Gas Consumption • Enamelled Body • Painted Pan Support • Aluminium Gas Burners • Bottom Cover OPTIONS: - Color: Black, Brown, White - Painted Top Cover - Ignitor

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

The NDIR bundle N2O is made up of optimally matched thin film infrared emitters and a corresponding IR thermopile detector to measure nitrous oxide in gas mixes. The kit has a short delivery time and therefore achieves measurement results in a short time. This is especially an advantage for developers in research projects with a limited time span. The two-channel detector's optical filter has been optimized for the absorption spectrum of N2O (CWL: 4525 ± 20 nm / HBW: 83 ± 6 nm) and can provide important data, especially in the analysis of exhaust gases in the automotive, railway and marine sectors, the monitoring of industrial exhaust emissions and environmental monitoring.

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

The NDIR bundle N2O is made up of optimally matched thin film infrared emitters and a corresponding IR thermopile detector to measure nitrous oxide in gas mixes. The kit has a short delivery time and therefore achieves measurement results in a short time. This is especially an advantage for developers in research projects with a limited time span. The two-channel detector's optical filter has been optimized for the absorption spectrum of N2O and can provide important data, especially in the analysis of exhaust gases in the automotive, railway and marine sectors, the monitoring of industrial exhaust emissions and environmental monitoring.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

The use of protective gases is an essential element of precise quality control (HACCP) in food packages (Modified Atmosphere Packaging = MAP). MAP gas mixers by WITT provide controlled gas quality and safety in your packaging process – for germfree and preserving food. WITT offers gas mixing and metering systems for all packaging machines used in the food industry, no matter if vacuum packaging, thermo forming, flow pack or chamber packaging machine. The gas mixing systems are adjusted to your specific product type and processing and require only basic installation requirements. WITT system solutions are developed in close collaboration with national food and research institutes. WITT is approved and certified according to ISO 22000 for food safety.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

WITT offers high-quality gas mixers / gas blenders and gas metering systems for two or more gases, for high flow rates and highly fluctuating gas withdrawals. You can choose between various options: According to your requirements, WITT gas mixers / gas blenders are available for nearly all technical gases and flow rates: for the optimal gas mixture for welding applications, the required gas concentration for food packages (modified atmosphere packaging = MAP) or the production of synthetic air for medical applications. State-of the art mechanical or electronic gas mixing systems provide accuracy and process safety. You can also control your gas mixing systems conveniently via Intranet, Internet or mobile devices. Combinations of WITT gas mixers / gas blenders with other WITT quality products such as gas analysers are also possible. They can be manufactured as complete system solutions.

Request for a quoteResults for

Gas mixing - Import exportNumber of results

33 ProductsCountries

Company type

Category

- Gas, compressed (10)

- Gas mixtures (2)

- Refrigerants (2)

- Sensors (2)

- Camping equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Chemicals - Basic Products & Derivatives (1)

- Cookers (1)

- Food Processing (1)

- Grids, gratings and wire mesh (1)

- Injection pumps and systems (1)

- LPG (1)

- Refrigeration plants and equipment, commercial and industrial (1)

- Rubber seals (1)

- Steam turbines (1)