- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- abrasives in grains

Results for

Abrasives in grains - Import export

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® DI-EU injector blasting cabinets are designed for use in production and maintenance. Ready for use equipped with integrated cartridge filter and abrasive recovery system. Economical operation with fine-grained abrasives with low air consumption of approx. 800 l/min. at 6 bar blasting pressure. The blasting media is continuously sucked out of the cabinet by a constant negative pressure and separated from dirt and dust in a downstream cyclone. A cyclone screen (possibly with ring magnet) collects coarse impurities. In this way, only clean abrasive remains in circulation. The used abrasive, dust and small impurities are led through the cartridge filter chamber to the dust collecting bucket.

Request for a quote

4CR INTERNATIONAL GMBH

Germany

Polyamide fabric coated Velcro sanding Stripes with an abrasive grain in a net form structure, perfect dust extraction and longer life, Dust-free sanding, less clogging and a perfect surfaces finish.

4CR INTERNATIONAL GMBH

Germany

Polyamide fabric coated Velcro sanding Stripes with an abrasive grain in a net form structure, perfect dust extraction and longer life, Dust-free sanding, less clogging and a perfect surfaces finish.

4CR INTERNATIONAL GMBH

Germany

Polyamide fabric coated Velcro sanding Stripes with an abrasive grain in a net form structure, perfect dust extraction and longer life, Dust-free sanding, less clogging and a perfect surfaces finish.

4CR INTERNATIONAL GMBH

Germany

Polyamide fabric coated Velcro sanding Stripes with an abrasive grain in a net form structure, perfect dust extraction and longer life, Dust-free sanding, less clogging and a perfect surfaces finish.

4CR INTERNATIONAL GMBH

Germany

Polyamide fabric coated Velcro sanding Stripes with an abrasive grain in a net form structure, perfect dust extraction and longer life, Dust-free sanding, less clogging and a perfect surfaces finish.

4CR INTERNATIONAL GMBH

Germany

Polyamide fabric coated Velcro sanding Stripes with an abrasive grain in a net form structure, perfect dust extraction and longer life, Dust-free sanding, less clogging and a perfect surfaces finish.

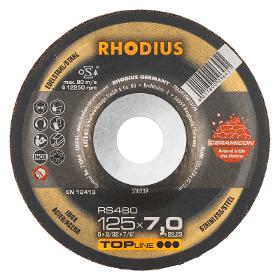

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Non-woven cleaning abrasive with ceramic high-performance abrasive grain. For powerful cleaning performance and an extremely long lifetime. • Stable edges • Top cleaning performance • With ceramic high-performance abrasive grains

RHODIUS ABRASIVES GMBH

Germany

Non-woven cleaning abrasive on 6 mm shank for removing rust and paint. • The open structure prevents clogging • Strong material abrasion through high grain concentration

RHODIUS ABRASIVES GMBH

Germany

Non-woven cleaning abrasive for mounting the matching SVS PIN for removal of rust and paint. • The open structure prevents clogging • High material abrasion through high grain concentration

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Continuous-feed belt with ceramic grain for stationary belt grinders. • Bond from synthetic resin with abrasive grain fillers for cooler grinding • Closed coating for high stock removal performance on steel and stainless steel • Tear-resistant X-polyester fabric, waterproof for a long lifetime

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Non-woven cleaning tool for the quick change system with ceramic high-performance abrasive grain. • Stable edges • Maximum cleaning performance • Quick tool change without bonding or sliding

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Flexible continuous-feed belt with ceramic grain for hand-guided belt grinders. • Bond made from synthetic resin enriched with abrasive grains for a cooler cut • Closed coating for high stock removal performance on steel and stainless steel • Flexible, tear-resistant cotton T-fabric for a long lifetime

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. High-performance stainless steel rough grinding disc with ceramic abrasive grain. Also performs very well on steel and cast iron. • High stock removal performance • Additional fabric flange from 180 mm for high-frequency and air grinders • Safe thanks to three full-face fabric layers

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The Lapmaster Model 48 is equipped with a 48 inch (1219mm) diameter lap plate. This is manufactured from Grade 300 grey cast iron to ISO 185(2005). It consists of individual segments bolted to a support plate. Outlets are provided to feed each conditioning ring via a track wire, with individual control valves. This system is designed so that a circulatory flow is established. The pump is capable of delivering far more compound to the outlets than is necessary. Excess compound is returned to the reservoir via a sloping drain tube. This together with the constant agitations provided by the stirrer minimises the tendency of the abrasive grains to settle out in the vehicle. The machine is intended for use with free abrasive compounds. A dispensing system, for use with water and diamond compounds etc., can also be fitted. Flatness of the machines lap plate, and consequently of the work, is controlled by adjusting the position of the conditioning rings relative to the lap plate track.

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

The JUNIOR 40 is a very handy device for various applications. It works according to the suction system, in which the blasting agent is sucked in the nozzle head by the compressed air (injector effect). The blown abrasive is filled into the sand container for re-use via the built-in insert vibrating screen and fed to the blasting nozzle. Depending on the desired surface, all dry blasting agents can be used, such as slag abrasives, glass beads, corundum, silicon, glass grain, chilled sand, etc.

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

The Injektor 80 Power is a very handy device for various applications. It operates according to the suction system, in which the blasting agent is sucked in the nozzle head by the compressed air (injector effect). The blown abrasive is filled into the sand container for re-use via the built-in insert vibrating screen and fed to the blasting nozzle. Depending on the desired surface, all dry blasting agents can be used, such as slag abrasives, glass beads, corundum, silicon, glass grain, hard sand, etc

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Abrasives in grains - Import exportNumber of results

17 ProductsCountries

Company type