- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bending pipes

Results for

Bending pipes - Import export

HS UMFORMTECHNIK GMBH

Germany

We can supply you with highly wear-resistant stainless steel pipe bends which have a service life 10 to 20 times longer than that of standard stainless steel pipe bends. This high degree of wear protection is required, for example for conveying fibreglass-reinforced plastic granules or similarly abrasive media. suitable for use of highly abrasive products easy installation no stepped pipe couplings and no flange connections required safe for use with food

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Along with highly wear-resistant stainless steel pipe bends of type HVA NIRO® we offer suitably highly wear-resistant branch pipes. They are available in in all sizes, diameters and angle degrees.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

The advantages to you: no more deformation of roundness when cutting bends on site easier extension-pipe/tiered pipe bend construction appealing visually pickled surface All of our pipes and pipe bends (both unannealed and annealed) are made of the following material: stainless steel pipe, material no. 1.4301 (AISI 304) longitudinal seam welded pipes hot rolled & cold rolled coils, unannealed, with or without pickling (W1) Make: IltaInox and/or Marcegaglia

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Glass pipe bends For conveying abrasive media or for high flow rates, we can supply you with glass pipe bends made from 3.3 borosilicate glass with a copper grounding strip. These have a service life at least 10 times longer than that of stainless steel pipe bends. made of 3.3 borosilicate glass leg extension 200 mm copper grounding strip attached at the outer radius

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

We produce aluminium pipe bends with the following characteristics and product specifications: DIN EN 573-3, 755-1, /-2 /-9

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Our speciality are thin-walled pipe-bends with large bending radius, especially for pneumatic conveying systems. The pipe-bends are cold-bent without any pleats on CNC-mandrel machines. Our quality management generally guarantees: welded seam smoothed or shaved (DIN 11 850 resp. DIN 17 457) absolutely wrinkle-free, no start-up bulges no scratching or scoring extremely low ovality visually aesthetic surface leg extension each side deburred sawing edges

Request for a quote

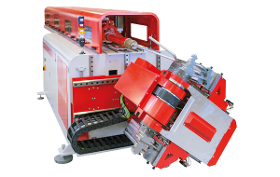

TRANSFLUID® MASCHINENBAU GMBH

Germany

We have developed these t bend machine solutions strong> for fast and efficient processing times. They are specifically tailored to the challenges of individual bends. Whether the system is manual or automated, they will deliver the best possible results. Highly efficient This manufacturing accelerator offers the profitable efficiency of our high performance bending machines for the manufacturing of hydraulics fittings together with Top Speed that is what the "AB" series stands for. For individual bends from 1xD to 1,500 mm bending radius for small and large radii, for demanding materials with thin walls, the high performance (HP) machine series guarantees the perfect bending result.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

In pneumatic conveying systems, conveying abrasive products – in particular at high conveying speeds – leads to abrasion and thus to wear in the pipe bends. In order to prevent this, the pipe bend of our highly wear-resistant DWR double-skin stainless pipe bends is encased in a second pipe bend, which creates a double-walled chamber. This acts, so to speak, as a “protective shield”: After the wear has taken place on the internal pipe bend, it fills with the product to be conveyed. When this process is completed, you are then conveying „product on product“ – and no further wear is possible! Version I: „Product-on-product” In this variant, the classic “double skin” comes into effect. not suitable for foodstuffs not suitable for material change Version II: „Lined with concrete” lined with extremely hard concrete colour: light grey not suitable for foodstuffs also available: lined with borosilicate glass

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Maximum bending freedom. The robotic bending technology combines the greatest versatility in manufacturing steps and simple handling. The robotic head is equipped with a clockwise and counterclockwise bending head, so that bending can happen in both direction once clamped. The eight synchronized and fully electric axes give maximum versatility when processing tubes. The bending process on tubes, including the processing at the ends and addon component can be done without any problems. The addon components can be positioned automatically, if needed. A radii/plane changer with up to 6 tools per bending system is integrated to give maximum flexibility..

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Stable, flexible and economical. This series will win you over with its special stability and performance. Individual pieces and small series can be produced in an extremely economical manner with this machine concept. The use of highvalue components ensure the machine's durability.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times.Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most extreme geometries on tubes. With our clockwise/counterclockwise bending machines – also available with push bending function – the most complex bends become reality with great accuracy.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Compact and very efficient. Our fully hydraulic mandrel bending machine delivers outstanding bend quality and very simple handling, with SPS control for preselection and storage of bending angles via a touch panel.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Fewer steps to the finished workpiece With t project you can see all the variables of the bending process before you start the production. Adapted to the material and collisionfree, it makes it possible to plan and execute complex bending geometries. The virtual bending simulation determines exact bending timings and cutting lengths; it also tests tube geometries in advance for feasibility. Tube data and bending results are documented with accuracy and they can then be replicated 100% . All the most common interfaces are available for the import and export of data and connection to BDE or ERP over the network.

Request for a quote

KW HYDRAULIK GMBH

Germany

Pressing Pipes Bending Pipes Striping and Peeling of Tube Brochure Tools for Pipeline Construction Drilling of Tubes Cutting and Sawing of Tubes Chamfering Tool for Plastic Tubes

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

We stock PE plates, PE pipes as well as custom made products HDPE plates in natural, PE 300, PE 500, PE 1000, in strengths from 2 mm etc PE pipes, pipe connections, PE pipe bends in different dimensions Custom made plastic vessels in accordance with drawing or pattern

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANTHERMO GMBH

Germany

Buttweld fittings according to ANSI B 16.9 Extensive stock range in special materials We can deliver Buttweld Fittings in numerous dimensions and materials directly from stock at short notice. Pipe bends with different radii (seamless and welded), T-pieces, reducers and caps essentially make up the product groups Buttweld Fittings (buttweld fittings). We only deliver goods of European origin. Special materials In particular, we supply special materials, which are generally only rarely requested, at short notice from our extensive range in stock. The following special materials are available at short notice: Low Temp Steel A 420 WPL6 / WPHY52 Chrome-Moly A234 Alloy WP5 Chrome-Moly A234 Alloy WP11 Chrome-Moly A234 Alloy WP22

Request for a quote

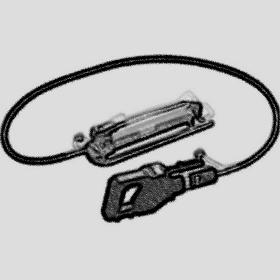

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Potentiometric displacement sensors are used for direct, precise measurement of mechanical displacements. The mechanical parts of the measuring equipment must be set-up in such a way that the sliding shaft can move without play or lateral forces. A special multi-finger slider ensures good contact even when the adjustment speed is high or in the presence of vibration. With its housing diameter of only 12.7 mm, the model 8709 is also suitable for highly compact structures. The movable fastening clamps allow the user variable options for attaching the sensor without complication. Optionally available adaptations, such as flange and ball joint versions, extend and complement the range of possible applications. Typical fields of application include: Measuring the stroke on riveting machines Measuring insertion distances Offset measurements on bearings Spring travel measurements on axes Measurements of the movement of hoisting platforms Length measurements on pipe bending machines

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The UBM 6-20 M is a universal bending device for steel pipes up to 20 mm OD. It comes with a set of bending rolls for common applications. An integrated scale for angle detection helps you to reach the required pipe dimension in only one work step. The telescopic lever keeps the operator’s forces low when bending rigid pipes. •Compact design •Compact for mobile usage •Standard with a set of 6 bendings rolls •User friendly •Easy handling •Simple adjustment •Wide workpiece range •Innovative design •Angle scale included •Telescopic lever

Request for a quote

ORBITEC GMBH

Germany

A precise 90° saw cut is a basic requirement for orbital weld preparation. Robust saws for all wall thicknesses Powerful drive motor Uniform and easy feed control by means of handwheel Different chamfering blades mountable Right-angled saw cut 4, 5 or 6 clamping jaws made of stainless steel as well as reducing jaws Due to concentric clamping no deformation with thin-walled pipes Also for cutting off pipe bends Quick-release fastener for easy changing of saw blades Chip removal during cutting by means of integrated brush Convenient adjustment of plunge depth by means of feed wheel Technical Data: Size range in mm: OD 6 – 220mm Size range in inch: 0.236″ – 8.661″ Wall thickness: 1 – 8mm Electric drive: Single-phase AC motor Mains voltage (input): 200/220VAC (50/60Hz) Power: 1000W / 4.5A Protection class: II Speed control: 6-step control Weight: 47 - 77kg Package includes: Tube saw with electric drive One saw blade One bottle of saw blade lubricating oil

Request for a quote

ENGEL-NETZE GMBH & CO. KG

Germany

with chafing protection | stainless steel accorate bending and melding handle pipe fitting to standard showel handles handle pipe inner diameter approx. 35mm Due to the special construction the frame is relatively light but very rigid. The brailer net bag is to be mounted to the inner frame. The outer frame prevents the mounting twine from being chafed off. When brailer nets are used in the fish processing industry the hygiene authorities might require the use of stainless steel frames.

Request for a quote

ENGEL-NETZE GMBH & CO. KG

Germany

with chafing protection | stainless steel accorate bending and melding handle pipe fitting to standard showel handles handle pipe inner diameter approx. 35mm Due to the special construction the frame is relatively light but very rigid. The brailer net bag is to be mounted to the inner frame. The outer frame prevents the mounting twine from being chafed off. When brailer nets are used in the fish processing industry the hygiene authorities might require the use of stainless steel frames.

Request for a quote

ENGEL-NETZE GMBH & CO. KG

Germany

with chafing protection | stainless steel accorate bending and melding handle pipe fitting to standard showel handles handle pipe inner diameter approx. 35mm Due to the special construction the frame is relatively light but very rigid. The brailer net bag is to be mounted to the inner frame. The outer frame prevents the mounting twine from being chafed off. When brailer nets are used in the fish processing industry the hygiene authorities might require the use of stainless steel frames.

Request for a quote

ENGEL-NETZE GMBH & CO. KG

Germany

with chafing protection | stainless steel Brailer frame | 30cm width | D-shape accorate bending and melding handle pipe fitting to standard showel handles handle pipe inner diameter approx. 35mm Due to the special construction the frame is relatively light but very rigid. The brailer net bag is to be mounted to the inner frame. The outer frame prevents the mounting twine from being chafed off. When brailer nets are used in the fish processing industry the hygiene authorities might require the use of stainless steel frames.

Request for a quote

ENGEL-NETZE GMBH & CO. KG

Germany

with chafing protection | stainless steel accorate bending and melding handle pipe fitting to standard showel handles handle pipe inner diameter approx. 35mm Due to the special construction the frame is relatively light but very rigid. The brailer net bag is to be mounted to the inner frame. The outer frame prevents the mounting twine from being chafed off. When brailer nets are used in the fish processing industry the hygiene authorities might require the use of stainless steel frames.

Request for a quote

SANHA GMBH & CO. KG

Germany

The premium installation system consists of high-grade NiroSan®-Industry press fittings with a red moulded sealing ring made from FKM (fluoro and perfluoro elastomers) for temperatures of up to 200 °C and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® Industry press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Industry press system and its components are certified in accordance with the rules and regulations of all important British and Continental certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The premium installation system consists of high-grade NiroSan®-Industry press fittings with a red moulded sealing ring made from FKM (fluoro and perfluoro elastomers) for temperatures of up to 200 °C and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® Industry press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Industry press system and its components are certified in accordance with the rules and regulations of all important British and Continental certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The premium installation system consists of high-grade NiroSan®-Industry press fittings with a red moulded sealing ring made from FKM (fluoro and perfluoro elastomers) for temperatures of up to 200 °C and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® Industry press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Industry press system and its components are certified in accordance with the rules and regulations of all important British and Continental certification bodies.

Request for a quoteResults for

Bending pipes - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Bending machine tools (9)

- Pipe and tube fittings - ferrous metal (8)

- Pipes and tubes - ferrous metal (7)

- Pipes and tubes, stainless steel (3)

- Pipes, bent - ferrous metal (1)

- Glass (1)

- Pipes and tubes, aluminium (1)

- Pneumatic tubes - systems (1)

- Power saws, portable (1)

- Rubber products (1)

- Sensors (1)

- Valves for sanitary fittings (1)