- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- robot system

Results for

Robot system - Import export

TRAPO GMBH

Germany

4- or 6-axis jointed-arm robots of various well-known brands are acting highly flexible. The high-speed systems palletize, sort, load and commission fast and high-precision single pieces, rows, partial layers or complete layers. - Low space requirement - Flexible use for various applications - Product and industry independent: Mature gripper technologies transport a wide variety of goods - Suitable for different packages and load carriers - Set on rails, the jointed-arm robot moves to different palletizing positions - Application-oriented, flexible combination of the optimally complementary technical properties of high-speed palletisers and robots

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Safe and powerful For an efficient body shell process, the correct bodywork components must be reliably brought from their intermediate storage areas and production lines to be assembled. Lödige’s materials handling and control solutions automate this procedure. Your advantages using Lödige solutions in the body shop: Connection to the pressed component store Conveying on several levels possible Connection to bodywork store Horizontal materials handling systems High levels of automation possible Control connection to robotic systems

Request for a quote

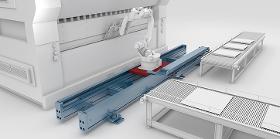

ROLLON GMBH

Germany

Shuttle system for moving robots and heavy loads for long distances with high dynamics. The motion system is available with recirculating ball guides or rollers while the driving system has been designed with rack and pinion. The shuttle is equipped with adjustable ties to achieve alignment even on irregular surfaces. Cable carrier and dampers at the stroke end are included. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

TRAPO GMBH

Germany

The TTS Series presents itself as highly flexible: TTS approaches conveyor lines and takes over individual loads or loads on load carriers, for example pallets. The particular advantage: TTS are flexibly adaptable to production processes. The variants and superstructures are geared to individual customer requirements: TTS are complemented by lift function, conveying systems or robot. Overall dimensions, energy transfer- and storage as well as drive and navigation can, on demand, be combined as desired.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Your expert in welding technics like MIG, MAG, WIG, resistance spot & stud welding, e-welding, welding robots For the returning serial welding tasks, 2 gantry welding robot system are available. With a machining length of up to 8 meters (26,2 ft), we can lealize complex customer requests thanks to 10 treatment axis performance. We are authorized to weld structural steelwork in accordance to EN1090

Request for a quote

TRAPO GMBH

Germany

With decades of know-how and worldwide expertise in the core areas of conveyor technology, robot systems, palletizing, depalletizing and automation, TRAPO AG presents itself as a renowned manufacturer and total systems supplier of conveyor systems, palletizing technology and packaging machines. Primary and secondary packaging such as cartons, trays, pails and more are palletized and depalletized. The machines in our systems impress with their flexibility, high performance and economic efficiency. We produce in Germany and set standards worldwide ranging from engineering contracts to automation. The palletizers of the HLP series operate with high and low inlet. The product range of the high-capacity layer palletizers is optionally equipped with a y-axis, rotary module or even a traversing axis — so that one or more palletizing stations can be operated as required.

Request for a quote

TRAPO GMBH

Germany

As a supplier of complete systems, TRAPO AG supplies modular High-Performance-Pick & Place-Systems that combine components such as robots, frame units, camera systems and conveyor technology. The modular system can be adapted to different framework conditions and thus covers almost any application. The TRAPO HPPS series forms the heart of the modular picker cell. The high-performance picker line combines maximum performance, individual TRAPO gripper technology and proven know-how, for example in the field of hygiene design.

Request for a quote

ELKON GMBH

Germany

ELKOBLOCK-36S single pallet concrete block making machine which is specially designed by experts in their field to produce different types of blocks such as interlocks, curb stones, hollow blocks, solid blocks, etc. has the capacity to produce concrete paving stone approximately 1.400 square meters in an 8 hours shift. Optimum operation is provided for production, curing, additional processing and packaking according to preferred method of single pallet concrete paving and block making machine which can be used with high performance finger car robot or cage system layout.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Powder systems with robots can be effectively used even for small batches. In addition to the classic method of powder coating using manual spray guns or masts, the demand for robot systems has risen sharply. Rippert offers the entire spectrum here too. Both powder-coating systems with robots and wet painting systems are supplied with intelligent software solutions. This also allows the economical processing of small lot sizes. Automatable high-speed paint changing systems have also been available for some time. Rippert plays a leading role in automated powder-coating systems with industrial robots.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Mobile, compact and multifunctional. Whether as manual spraying equipment or on a fully automatic robot spraying system, the compact supply tank with its 45 litre stainless steel tank is suitable for all tasks. Equipped as standard with a pneumatic lifting device, handling is particularly easy. By using proven components, the sprayer is perfectly suited for continuous operation. The device is suitable for spraying lubricants or coatings with a high solid content. To change the tank or clean it, the complete tank cover with all attachments is lifted pneumatically.

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming and scoring hidden airbag compartments on thermoformed skin. After the fabrication of IP skins through thermoforming, two separate fabrication steps are still needed before foaming. In the first step, the thermoformed skin will be trimmed in the external zone through punching or a blade cutting process. Depending on the requirements, this is where FRIMO's blade cutting equipment comes into operation. In the second step, the skin will be weakened in the airbag area by a blade. By using the new FRIMO FlexTrim Combi Trim Scoring machine, both steps can be realised at once. The skin is positioned in a common component fixture and finished with two different cutting tools. The new system concept, with its flexible design and layout possibilities, offers a variety of options for combinable process and operation groupings. As an example : one 2-station system with two robots, which are equipped with automatically exchangeable cutter heads, and where two different products

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V6LS from the FD series impresses with its slim design and an expanded degree of freedom, which enables a constant torch orientation when immersing in tight work spaces. Compared to the V6S, the V6LS has an extended arm, which is why the range is increased again. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2006 mm Max. payload: 6kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6000 W Weight: 316 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4S from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1435 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3550 W Weight: 189 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V20S from the FD series is the optimal robot for medium-heavy loads. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1710 mm Max. payload: 20kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6600 W. Weight: 321 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4LS from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. In addition, the FD-B4LS offers an extended arm compared to the FD-B4S and thus a larger working radius. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2008 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 5650 W Weight: 321 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

Metalworking companies are increasingly looking for practical solutions on how to quickly and easily carry out welding tasks. For small quantities, however, automation systems for welding have so far been difficult to implement, from an economical point of view. At the same time, it is becoming increasingly difficult to find qualified welders for manual processing. OTC DAIHEN EUROPE has developed EASY ARC, a new mobile welding robot system for workshop operation, which meets the economic and pragmatic requirements. EASY ARC includes a compact welding robot with intuitive OTC Easy-Teach control, which offers the operator with the perfect weld seam, thanks to the integrated expert system and manufacturer’s own 400A MIG / MAG power source inverter. The robot is mounted on a welding table that is prepared for holding standard clamping elements and equipped with rollers. The simple conversion of the system thus ensures appropriate flexibility in production.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Venjakob has combined – for the first time in the industry – a robot with a surface spray painting machine. VEN SPRAY VARIO offers the flexibility of an industrial spray coating robot and the high output of an automatic surface spray coating machine. The outer edges of the parts are precisely coated by the robot, and the surfaces are sprayed "inline" at a constant throughfeed speed without any stopping or stop and go by the spray guns of the downstream linear axis. In comparison to the usual Cartesian robot systems on the market, this leads to an approx. 50 % higher lacquering performance(surface|minute). In addition, the new system technology optimises the surface quality, as it leads to visibly better results by linking the paint film at transitions from surfaces to outer edges. Another decisive system advantage of the VEN SPRAY VARIO is the ongoing guarantee of reproducible production qualities. The perfect finish of 3D workpieces is particularly impressive. For coating complex 3D parts as a stationary batch we recommend using the optionally available paper belt transport system. In addition to the described flexibility, the plant technology can also be used for surface coating only. As an alternative to a manual spraying station a single robot can be used for complex geometries. The technically sophisticated paint recovery system achieves maximum efficiency. The recyclability of the recovered overspray and the considerably reduced use of cleaning agents provide an impressive energy balance. In addition, the efficient ventilation technology noticeably reduces the resulting energy costs. The modular design ensures a safe investment in the long term. The integration of additional robots and other adjustments to meet the continuously growing demands on our customers' production processes are possible at any time.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

W&K METALLVERARBEITUNG GMBH

Germany

Due to their high productivity, robotic welding systems offer cost advantages over manual welding, given the corresponding quantities. Benefit from high productivity and efficiency through perfectly matched welding components and fascinatingly good welding results of your products.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The K Series painting robots combine high mileage with powerful programming flexibility. With six explosion-proof models, Kawasaki has the right robots for every robot-controlled painting application, from the painting cell with individual robots to integrated multi-robot painting systems. The KF193E is a K-Series industrial robot manufactured by Kawasaki. It has a payload wrist of 12kg and arm of 20kg, a horizontal reach of 1,973mm, a vertical reach of 2,887mm, a maximum painting speed of 1,200mm/s, a weight of 720kg, a floor mounting position, and a 3R ø40 mm that can do a triple roll with its hollow wrist. The industrial robot was specifically created for painting applications.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The K Series line of painting robots combines high operational performance with powerful programming flexibility. With six explosion-proof models available, Kawasaki has a robot that will suit any robotic painting application, from a one robot paint cell to complete multi-robot integrated finishing systems.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The K Series line of painting robots combines high operational performance with powerful programming flexibility. With six explosion-proof models available, Kawasaki has a robot that will suit any robotic painting application, from a one robot paint cell to complete multi-robot integrated finishing systems.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The K Series line of painting robots combines high operational performance with powerful programming flexibility. With six explosion-proof models available, Kawasaki has a robot that will suit any robotic painting application, from a one robot paint cell to complete multi-robot integrated finishing systems.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The K range of painting robots blend top notch operational performance and robust configuration flexibility. It can be ordered in seven distinct models, which ensures that Kawasaki has a robot model that will be a perfect fit for any application from a single robot painting cell all the way up to a full multi robot appointed finishing systems. The specifications of the K-Series painting robots include 12 kg, arm 20 kg payload wrist, 2,665 mm horizontal reach, 4,107 mm vertical reach, 1,200 mm/s maximum painting speed and 3R ø40 mm (Roll Roll Roll - hollow wrist). This series of painting robots is best suited for painting applications.

Request for a quote

ROTEG AG ROBOTER TECHNOLOGIE

Germany

The three axis of motion enable a high performance and an efficient design of the robot system. The central pick up table picks up a whole layer of glass from the pallet. The table pushes the layer on the discharge table in one operation which seperates the glasses and transfers them to the production line. Since the roTeg depalletizing robot DERO II works with clamping jaws, numerous package sizes can be processed without mechanical devices. In each depalletizing cycle the interlayers are also picked up by the glass layer and collected in a magazine. The movability of the robot construction on the x axis enables the handling of different production lines. While one discharge table is still filled with glasses and being emtied line by line the DERO II already takes the next layer and serves the second discharge table.

Request for a quote

ROTEG AG ROBOTER TECHNOLOGIE

Germany

The palletizing robot system PARO® has a modular structure. This is how the palletizing room can be optimally adapted to the palletizing task – even afterwards. The spectrum ranges from standard single place cells which are not bigger than the pallet itself, to palletizing systems with twelve or more palletizing stations. All of this is easily determined by a correspondingly long horizontal axis. The palletizing robot PARO® is a four-axis robot whose axis have a special guide system: Profiled, teflon coated Vulkollanrollers run on polished stainless steel tubes. This system has proven itself to be robust and maintenance free. With this simple system technology a lot of industrial handling processes are economically automated in different performance areas. The PARO® is durable and also suitable for the use in extreme enviroments. All in all the robot offers a good price-performance ratio.

Request for a quoteResults for

Robot system - Import exportNumber of results

26 Products