- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- carbide cutting

Results for

Carbide cutting - Import export

RONIX GMBH

Germany

Ronix SDS Plus Drill Bit Ø 6mm is heat-forged for strength and longevity with a sharp Tungsten Carbide Tip edge which is designed for maximum impact on masonry/concrete material by allowing for effective and precise hammer drilling. The shank is made of heat-forged and hardened steel. The material used for the tip is tungsten carbide which makes this Ronix hammer drill bit easy and reliable inside deep and heavy-duty masonry, reinforced concrete, tile, brick and cinder block. Ronix SDS Plus Drill Bit Ø 6mm feature 2-flute self-centering carbide tips which ensure fast cut speed and maximum lifetime. The flutes are specially designed to allow maximal amount of concrete removal for both ease of use and effectiveness in concrete/masonry drilling and hammer drilling.

Request for a quote

RONIX GMBH

Germany

Ronix SDS Plus Drill Bit Ø 10mm is heat-forged for strength and longevity with a sharp Tungsten Carbide Tip edge which is designed for maximum impact on masonry/concrete material by allowing for effective and precise hammer drilling. The shank is made of heat-forged and hardened steel. The material used for the tip is tungsten carbide which makes this Ronix hammer drill bit easy and reliable inside deep and heavy-duty masonry, reinforced concrete, tile, brick and cinder block. Ronix SDS Plus Drill Bit Ø 10mm feature 2-flute self-centering carbide tips which ensure fast cut speed and maximum lifetime. The flutes are specially designed to allow maximal amount of concrete removal for both ease of use and effectiveness in concrete/masonry drilling and hammer drilling.

Request for a quote

RONIX GMBH

Germany

Ronix SDS Plus Drill Bit Ø 12mm is heat-forged for strength and longevity with a sharp Tungsten Carbide Tip edge which is designed for maximum impact on masonry/concrete material by allowing for effective and precise hammer drilling. The shank is made of heat-forged and hardened steel. The material used for the tip is tungsten carbide which makes this Ronix hammer drill bit easy and reliable inside deep and heavy-duty masonry, reinforced concrete, tile, brick and cinder block. Ronix SDS Plus Drill Bit Ø 12mm feature 2-flute self-centering carbide tips which ensure fast cut speed and maximum lifetime. The flutes are specially designed to allow maximal amount of concrete removal for both ease of use and effectiveness in concrete/masonry drilling and hammer drilling. Ronix SDS-Plus Drill Bits are made of steel and heat-forged for absolute strength and longevity with a sharp Carbide.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The HCS MULTI-FLUID is a series of carbide circular saw manufactured by Eisele. The key highlights of the HCS MULTI-FLUID series include a firm base frame that is welded, a bigger scope of cutting, an arbitrary saw blade that is accessible to ensure maximum cutting scope that can reach up to 180 mm . The machine has a sturdy and robust base frame on which the combined sawing unit and material feed unit are mounted. This structure combined with a very robust machine design ensures a smooth sawing process with excellent cutting results and a long service-life of the saw blade. The Multi-Fluid system is excellent for high-alloy stainless steels and tool steels, nickelbasedalloys like Inconel and Hastelloy as well as titanium alloys. Depending on the requirements, the following cooling/lubrication components can be combined in a most effective way: — Coolant nozzles for wet processing — Micro-spraying device for minimum quantity lubrication — Cooling vortex tube for dry cutting

Request for a quote

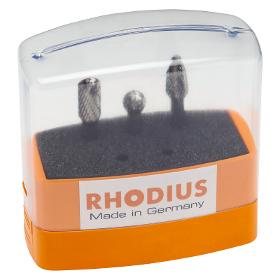

RHODIUS ABRASIVES GMBH

Germany

Carbide burr set, consisting of the three/five most popular carbide burr shapes. • Double cut for high material abrasion • Attractive plastic box for easy storage

Do you sell or make similar products?

Sign up to europages and have your products listed

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The BDW is designed to reface the seating provided in the engine block for receiving the flange of the cylinder liner. Capacity Refacing diameter range 90-180mm Features Centering in the cylinder bore is automatically effected by simply turning the centering spindle. The studs at the engine block are used for rigidly clamping the BDW to the engine block. The seating is refaced to the preset depth by the simultaneous application of both a rotary and a transverse feed motion to the single point cutting tool. While the single point carbide cutting is rotated around the seating, a feed gear mechanism ensures a transverse feed motion. An adjustable depht stop makes sure that all seatings are cut to the same depth.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Working Principle: The counterbore is machined to the preset depth by the simultaneous application of both a rotary and vertical or horizontal feed motion to the carbide cutting insert. While the cutting insert rotates in a circle around the counterbore, a feed gear mechanism ensures a continuous feed motion. The lathe-type refacing action provides smooth and closely fitting contact surfaces for oversize valve seat rings. Features: The motor drive unit of the VD4HD-ADM is identical with the motor drive unit of the VD4HD Valve Seat Refacing Machine and, therefore, is only required, if no VD4HD is at hand. Two types of exchangeable boring gear heads are available. The standard AV boring head is provided with a vertical slide for counterboring. The optional AVH boring and facing head is provided with a vertical and a horizontal slide for counterboring and facing the bottom of the bore.

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Aluminium alloys • Aluminium bronzes • Copper alloys • Sand cast aluminium and cast magnesium • Graphite

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • All-purpose use for construction steel, low-alloy steel, cast iron, aluminium, copper and bronze • Solid material in medium and large dimensions

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Titanium alloys • Metals with high residual stress • Stainless steels • Special alloys • Abrasive non-ferrous metals and graphite

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

With the DHC Premium solid carbide end mills, LMT Tools significantly increased the performance of the low-vibration premium tools: 25 % added machining volume is the result of different helix angles in connection with newly developed, stable front cutting edges and peripheral teeth. Additionally, the new cutting material LCPK30M including an innovative PVD high-performance coating contributes to an improved tool life and a safe chip removal. A special performance feature of the DHC Premium end mill (Different Helix Cutter) by LMT Fette consists in its multifunctionality: it allows the user to rough and finish with the same tool. It can also produce narrow projections and up to 2xd-deep slots in steel and cast materials with exceptional surface quality. Advantages: - Increase of the machining volume by 25 % - Increased process reliability due to stable cutting edges - Multifunctional – roughing and finishing with the same tool

Request for a quoteResults for

Carbide cutting - Import exportNumber of results

12 ProductsCountries

Company type