- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas turbines

Results for

Gas turbines - Import export

IMM MASCHINENBAU GMBH

Germany

CNC polishing of compressor blades and vanes to optimize flow efficiency while at the same time minimizing differences due to tolerances in blade geometry. This is essential to the balancing of the compressor rotor and the fit of the stator parts. The SPE allows to keep up with the demand of this for the latest F-Class & H-Class Gas Turbine Compressors. The SPE CNC-Machine allows automatic polishing of all rows of the Gas Turbine Compressor, as well as most rows of Steam Turbine Blades within tight tolerances and highest repeatability. A dedicated CAD/CAM software allows for generation of NC part programs. As the SPE is a cartesian type machine tool there is no need for referencing or time consuming in process gauging. The precision and repeatability of the process allows the balancing of the milling process to leave a rougher scallop on the blade and save valuable time and cutter on the milling side. Capable of polishing compressor blades, fan blades and vanes up to 550 mm in length.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC machine tool with 6 axis for belt grinding, polishing and belt linishing aircraft engine airfoils such as fan blades, vanes (OGVs and IGVs), steam turbine blades and gas turbine compressor blades and vanes. Extreme high precision and repeatable stock removal allows balancing of milling process to save milling time and cutter costs by maximizing milling roughness followed by MTS process.

Request for a quote

BORSIG GMBH

Germany

BORSIG has been manufacturing centrifugal compressors for process gases for almost 60 years. The BORSIG centrifugal compressor series comprises multistage integrally geared centrifugal compressors with up to 8 stages, with steam turbine, gas turbine or electric motor as driver with all auxiliary equipment (turnkey solutions) according to customer’s requirements. The compressors comply with the corresponding API design standards such as API 617 (chapter 3) and 672 (4th edition). The oil system is designed according to API 614 or manufacturer's standard. The development is based on the latest research results in fluid mechanics as well as in gear and bearing design.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Castrol Anvol PE 46 B (07.09.2020) Flame-retardant hydraulic fluid Description The flame-retardant hydraulic fluid Castrol Anvol PE 46 B is based on defined, hydrolytically stable phosphoric acid esters. Castrol Anvol PE 46 B is a hydraulic fluid to be labeled as HFD 46 in accordance with DIN 51 502 or as HFDR 46 in accordance with ISO 6743-4 . Castrol Anvol PE 46 B complies with VDMA standard sheet 24 317 "Guidelines for flame-retardant hydraulic fluids" (type HFDR). The liquid is PCB-free. Application Castrol Anvol PE 46 B is preferably used as a hydraulic fluid in electro-hydraulic control systems of steam turbines. It was developed specifically for this purpose. Used as a circulation lubricant, Castrol Anvol PE 46 B is suitable for bearing lubrication of steam and gas turbines, provided they are designed for this group of materials, and it is used as a hydraulic fluid in industrial hydraulics that work in fire-hazardous environments.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembly lubrication of screw connections of high-strength steel subject to high temperatures, corrosive influences in chemically aggressive environments, e.g. on gas and steam turbines in power plants, combustion engines, threads on pipe fittings, flange joints and fittings in superheated steam lines, exhaust pipe and combustion chamber screwed connections etc. Parting lubrication of materials with a tendency to seize up, e.g. V2A, V4A and high-temperature steels Advantages and benefits Excellently suited for preventing seizing and binding Highly effective against corrosion affects Free of lead compounds, sulphides, chlorides and fluorides For best adhesion, clean the threads and sliding surfaces from dirt and other lubricants. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply paste evenly in sufficient amount onto head/nut support and thread or onto the sliding areas with brush, spatula, etc.

Request for a quote

BORSIG GMBH

Germany

With around 160 years of manufacturing expertise in reciprocating compressors, BORSIG offers tailor-made horizontal and vertical compressor solutions for process gases with all auxiliary equipment (turnkey solutions). Our reciprocating compressors are driven either by electric motors, gas engines or steam turbines. They have been developed for heavy continuous operation with lubricated or non-lubricated cylinders. They comply with the design standards of API 618 (5th edition), API 11P/ ISO 13631 as well as other international and manufacturing standards. BORSIG reciprocating compressors stand for long life, high wear resistance and low life cycle costs.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Regardless of whether gas engine, compressor and turbine oils, standard hydraulic oil, bed track oil or synthetic high-performance grease: with our wide range of products, we offer the right product for every application. Our specialists are on hand to provide you with help and advice and to inform you about. They will also advise you on industry-specific solutions, such as products for the paper industry or special lubricants that are required for machines within the scope of manufacturer approvals. Our aim is to work out a sensible and efficient solution for your needs.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Ideal for combination with combined heat and power units or gas turbines — Environmentally friendly generation of steam and hot water from available waste heat — High efficiency through efficient tubular heat exchanger and thermal insulation — Cost-efficient to purchase and operate as no burner is necessary

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Conventional fired heat generator with additionally integrated smoke tube pass for waste heat utilization — Environmentally friendly generation of thermal heat or process heat through the utilisation of waste heat sources — High supply reliability thanks to self-firing function — Robust, reliable and durable — Versatile design for use with different fuel types and as a multi-fuel firing unit (oil, gas, biogas, hydrogen) — Ideal for combination with combined heat and power units or gas turbines

Request for a quote

STARRAG GMBH

Germany

No matter if it is called a «Blisk» (bladed disk) or an «IBR» (integrally bladed rotor), no matter if it is single stage or multi stage, Starrag’s dedicated machine concept of the NB series provides the best solution for efficiently machining these parts. Blisks made from Titanium, Nickelbased superalloys and the Blisks made of blade steels for stationary gas turbines triggered the development of the NB series. For all the necessary manufacturing operations Starrag provides the benchmark Efficient roughing for Blisks machined from solid, adaptive machining for friction welded Blisks, high dynamic finishing of the airfoils in point contact. Shortest cycle times and zero scrap rate production are achievable on the Starrag NB series. The NB series is based on the very successful Starrag LX series.

Request for a quote

STARRAG GMBH

Germany

No matter if it is called a «Blisk» (bladed disk) or an «IBR» (integrally bladed rotor), no matter if it is single stage or multi stage, Starrag’s dedicated machine concept of the NB series provides the best solution for efficiently machining these parts. Blisks made from Titanium, Nickelbased superalloys and the Blisks made of blade steels for stationary gas turbines triggered the development of the NB series. For all the necessary manufacturing operations Starrag provides the benchmark Efficient roughing for Blisks machined from solid, adaptive machining for friction welded Blisks, high dynamic finishing of the airfoils in point contact. Shortest cycle times and zero scrap rate production are achievable on the Starrag NB series. The NB series is based on the very successful Starrag LX series.

Request for a quote

STARRAG GMBH

Germany

No matter if it is called a «Blisk» (bladed disk) or an «IBR» (integrally bladed rotor), no matter if it is single stage or multi stage, Starrag’s dedicated machine concept of the NB series provides the best solution for efficiently machining these parts. Blisks made from Titanium, Nickelbased superalloys and the Blisks made of blade steels for stationary gas turbines triggered the development of the NB series. For all the necessary manufacturing operations Starrag provides the benchmark Efficient roughing for Blisks machined from solid, adaptive machining for friction welded Blisks, high dynamic finishing of the airfoils in point contact. Shortest cycle times and zero scrap rate production are achievable on the Starrag NB series. The NB series is based on the very successful Starrag LX series.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Synchronous generators from LDW are highly versatile and are used in shipbuilding, power stations and many other applications. Our generators can be driven by gas, steam or water turbines as well as diesel engines and other drivers. Synchronous generators from LDW have a high degree of efficiency and operate with extreme effectiveness. We develop and manufacture generators of the highest quality standards.LDW supplies synchronous generators with an output range from 4,000 to 60,000 kVA.Our synchronous generators are specially optimised for the specific application of the customer, e.g. if used for water power turbines with regard to runaway speed and turbine force absorption. Where diesel generator sets are used, the vibration load in particular is taken into account. On request, we will also construct the generator with a forged-on flange. A high degree of efficiency is ensured for all generators.

Request for a quote

NORIS GROUP GMBH

Germany

Modern, elegant and unique – Individual bridge design for a uniform look & feel on your bridge The NORISYS 4 automation platform not only offers components for remote control and monitoring, but also control and display panels for a modern, timeless and uniform bridge design. The modular system provides flexibility and a space-saving, ergonomic design, whilst making your bridge a special and attractive place to be. The automation platform offers all the interfaces you will need to integrate systems from your technology partners (navigation, engine monitoring, lighting, horn control, etc.). Your bridge will be individually designed just for you, making it completely one of a kind. It will be developed to meet the specific requirements of your ship or yacht and adapted to your wishes and needs. Almost all drive types can be integrated (CPP, FPP, azimuth/pump jet, water jet, gas turbine, booster or hybrid drives), along with all technology partners.

Request for a quote

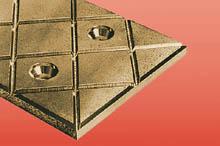

OGE GROUP

Germany

Bases Exhaust diffusers Plenums Inlet Ducts Exhaust Ducts Exhaust Casings Inlet Collectors Exhaust Collector Air Intake Manifolds for gas turbines Piping Vessels Small high alloy parts

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Büttner's fash-tube dryers are most versatile and extremely ecient. The dryer systems are used for drying material having high levels of surface moisture or a specic surface area. They are, for example, used to pre-dry wood akes before they are conveyed into drum dryers. Flash tube dryers are also used as the principal dryers for drying bres to be used in MDF production. For many years Büttner's ash tube dryers have been in operation successfully in many dierent industrial sectors all over the world Features Water evaporation of up to more than 70 t/h per unit depending on the product Drying within just a few seconds, the material is then already mechanically separated and conveyed to the downstream drum dryer. Flash tube dryers may be heated in many dierent ways, for example: Flue gas from grate ring Büttner gas line burners Hot gas from gas turbines or gas motors Indirectly by heat exchangers for steam or thermal oil Any combination of the heating methods mentioned above

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

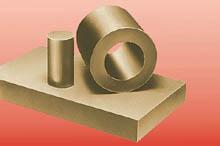

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

WTC - TRADING COMPANY

Germany

Jet fuel is a type of aviation fuel designed for use in aircraft powered by gas-turbine engines. It is clear to straw-colored in appearance. The most commonly used fuels for commercial aviation are Jet A and Jet A-1 which are produced to a standardized international specification.

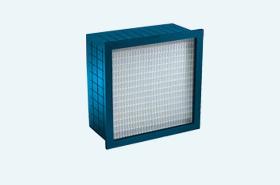

AEROFIL INTERNATIONAL GMBH

Germany

AERO CELL GT are deep pleated box style filters with medium efficiencies. It is made from micro fine fiberglass paper media and comes with metal frames. Filters are available in M6 and F8 efficiencies. We offer this is a double header construction. These filters are specially designed to operate in harsh conditions such as Gas Turbines and Air

Request for a quote

AEROFIL INTERNATIONAL GMBH

Germany

Aero Panel G model features Panel filters in Glassfiber media. They are available in 25mm, 50mm and 90mm thicknesses and in various models depending upon application. It is a right choice and economical pre filter for Fan Coil Units & Packaged Units as pre filtersand as disposable pre filters in AHUs and Gas Turbine applications.

Request for a quote

AEROFIL INTERNATIONAL GMBH

Germany

AERO CELL V HEPA GT filters are the new generation type of high efficiency MiniPleat compact HEPA filters available in a wide range of efficiencies from E10 to E12. AERO CELL V HEPA GT filters are designed to use in HVAC installations where highest degree of air cleanliness is required. The high burst resistance, low pressure drop and high dust holding capacity offered by the filter made it an ideal filter for extreme operating conditions like Gas turbine air intake fine filtration. This filter perfectly suits the third stage filtration levels in Gas Turbines after a normal G4 pre filter and F7, F8 or .

Request for a quote

AEROFIL INTERNATIONAL GMBH

Germany

AERO CELL GTP filters are the new generation type high efficiency minipleat box filters available in efficiencies F8 / MERV14, F9 / MERV15 & H10/MERV16. These filters are designed to use in Gas Turbine Systems, VAV systems and Oil Mist Collection. The compact design, larger surface area and low initial resistance made it an ideal alternative to ordinary Bag filters & Box type filters of the similar efficiencies.

Request for a quoteResults for

Gas turbines - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Air filtration equipment (4)

- Machine tools, metal machining - parts and accessories (3)

- Gas turbines (2)

- Lubricants, industrial (2)

- Boilers, industrial (2)

- Compressors (2)

- Steam turbines (2)

- Turbines (1)

- Electricity generators (1)

- Fuel, petrol and diesel economy systems (1)

- Oiling - machines and systems (1)

- Polishing - machine tools (1)

- Polishing equipment and materials (1)

- Ship furnishings (1)

- Silicones (1)

- Wood veneer - machinery and equipment (1)