- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- handling%20-%20machines%20%20&%20%20equipment

Results for

Handling%20-%20machines%20%20&%20%20equipment - Import export

IGUS® GMBH

Germany

The twisterchain product line offers a wide range for circular movements and is available in four sizes. Modular in width and radius, therefore flexible in applications where rotary and spiral movements up to 360° and more with high loads and smooth operation are required. The twisterchain applications are available with guide trough, which has the following advantages: guidance of the energy chain, reduced abrasion of the energy chain, optimal operational smoothness, rotation angle up to 360° from stock. - Strong, high fill weights, smooth operation, weight-optimised - Rotary speeds up to 1m/s and more - Circular/spiral movements up to 360° from stock (up to 400° upon request) - Cable-friendly, smooth interior crossbars openable along the inner and outer radius - Successfully tested for over 1 million cycles in the igus laboratory

Request for a quote

U.I. LAPP GMBH

Germany

SKINTOP® cable glands ensure a secure connection in a matter of seconds. The universal systems are simple, perfect and easy to install: simply insert the cable, close and go. The cable is securely fixed, centred and hermetically sealed. Properties: — Universal, quick and easy to assemble. — High operational safety and reliability even under strenuous conditions. — The perfect fit for every requirement due to a range of versions and comprehensive accessories. — Plastic and metal versions. — Also with bending protection for mobile use. — Also halogen-free.

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

Special tool balancer with double cable for extra safety. Facts: Dual-cable design Freely rotating and swivelling safety hook for suspension, adjustable Housing and housing cover of high-strength pressure-cast aluminum Cable drum of high-strength chill-cast aluminum Closed ball bearings on both sides High-strength, encapsulated special suspension spring High-strength steel cables Infinitely adjustable cable stop buffer Cable wedge allows infinite adjustment of cable length Screw-type spring hook for load suspension Infinitely variable load setting via endless screw Patented freewheel protects against overrotation when the spring is released

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

Facts: Freely rotating and swivelling safety hook for suspension, adjustable Housing and housing cover of high-strength pressure-cast aluminum Cable drum of high-strength pressure-cast aluminum Closed ball bearings on both sides High-strength, encapsulated special suspension spring High-strength steel cable • Infinitely adjustable cable stop buffer Cable wedge allows infinite adjustment of cable length Screw-type spring hook for load suspension Infinitely variable load setting via endless screw Patented freewheel protects against overrotation when the spring is released Available with and without manual lock.

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

Facts: reely rotating and swivelling screw-type spring hook for suspension Housing and housing cover of chill-cast aluminum Cable drum of high-strength chill-cast aluminum Closed ball bearings High-strength special suspension spring High-strength steel cable Infinitely adjustable cable stop buffer Screw-type spring hook for load suspension Infinitely variable load setting via endless screw Available without (Type 7235) or with (Type 7236) ratchet lock Safety: GS Certificate / DIN15112 / Made in Germany

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

Balancers are holding tools in a waiting position. The needed tools in production are always ready for use. They increase safety and ergonomics at workplace. Features: Safe suspension with freely rotating and swivelling screw-type spring hook Housing of very impact-resistant and abrasion-resistant plastic Housing cover of painted sheet steel Cable drum of high-strength, abrasion-resistant plastic High-strength special suspension spring High-strength steel cable Infinitely adjustable cable stop buffer Cable wedge allows infinite adjustment of cable length Screw-type spring hook for load suspension Simplified load setting

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

Spiral hoses available in 9 x 13 and 11 x 16 variants Max. operating pressure 10 bar Safe suspension with freely rotating and swivelling screw-type spring hook Housing of very impact-resistant and abrasion-resistant plastic Cable drum of abrasion-resistant plastic High-strength special suspension spring High-strength steel cable Infinitely adjustable cable stop buffer Cable wedge allows infinite adjustment of cable length Screw-type spring hook for load suspension Infinitely variable load setting Available without (Type 7221) or with (Type 7222) ratchet lock Rigid, impact-resistant design Electrically insulated suspension via screw-type spring hook (freely rotating and swivelling design) Includes safety chain as fall protection Mechanism for locking the cable drum High-strength special suspension spring Spring fracture safeguard is standard Includes ferrule for securing the cable end GS-certificate

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

Facts: Spiral hoses available in 9 x 13 and 11 x 16 variants Max. operating pressure 10 bar Safe suspension with freely rotating and swivelling screw-type spring hook Housing of very impact-resistant and abrasion-resistant plastic Cable drum of abrasion-resistant plastic High-strength special suspension spring High-strength steel cable Infinitely adjustable cable stop buffer Screw-type spring hook for load suspension Easy load setting Available without (Type 7211) or with (Type 7212) ratchet lock Safety: Closed unit Rigid, impact-resistant design Electrically insulated suspension via screw-type spring hook (freely rotating and swivelling design) Includes safety chain as fall protection High-strength special suspension spring Spring fracture safeguard starting at 3.0 kg load capacity Screw-type spring hook for load suspension GS-certified

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

The Retractor Type 7221 is holding tools up to 14 kg for an ergonomic and safety work place.

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

Facts: Cable travel: A longer cable is available upon request Safe suspension with freely rotating and swivelling screw-type spring hook Housing of very impact-resistant and abrasion-resistant plastic Cable drum of abrasion-resistant plastic High-strength special suspension spring High-strength steel cable Infinitely adjustable cable stop buffer Cable wedge allows infinite adjustment of cable length Screw-type spring hook for load suspension Infinitely variable load setting Available without (Type 7221) or with (Type 7222) ratchet lock Safety: Closed unit Rigid, impact-resistant design Electrically insulated suspension via screw-type spring hook (freely rotating and swivelling design) Includes safety chain as fall protection Mechanism for locking the cable drum High-strength special suspension spring Spring fracture safeguard is standard GS certified

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

Facts: Cable travel: A longer cable is available upon request Safe suspension with freely rotating and swivelling screw-type spring hook Housing of very impact-resistant and abrasion-resistant plastic Cable drum of abrasion-resistant plastic High-strength special suspension spring High-strength steel cable Infinitely adjustable cable stop buffer Light-duty spring hook for load suspension Easy load setting Closed unit Rigid, impact-resistant design Electrically insulated suspension via screw-type spring hook (freely rotating and swivelling design) Includes safety chain as fall protection High-strength special suspension spring Screw-type spring hook for load suspension GS-certified

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Part size: max. 50 x 50 x 50 mm Part weight: max. 80g / part Bunker volume: 10 – 50 litres (depending on parts) Feeding speed: max. 30 m/min. (depending on part geometries)

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

With the LeviWafer-Gripper Transport system it is possible, to lift and transport sensitive Wafers contactless. In combination with the transport, (un)loading of stacks and cassettes is also possible. The gripper uses ultrasonic bearing technology to keep the wafer at a distance, thus enabling contactless transport. In addition to micro-scratches and -cracks, contamination by particles is avoided since without compressed air no air turbulence is created. Therefore, the gripper is also very suitable for clean rooms. The LeviWafer-Gripper can be designed with a single or double paddle. Features of the LeviWafer-Gripper: - Contactless pickup - No micro-scratches, micro-cracks, or particles - Suitable for standard cassettes - Low energy consumption - Customizable according to customer specifications

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

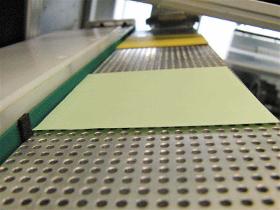

The LinearLevi-Conveyor enables the contactless transport of sensitive materials and prevents micro-scratches as well as contamination. With the LinearLevi-Conveyor, the workpieces can be guided along defined lines, without any points of contact and without the use of compressed air. Due to the Ultrasonic Suspension Technology, the substrate is kept at a distance, which prevents micro-scratches and contamination. During the transport, a high flatness also on flexible substrates is provided. Features of the LinearLevi-Conveyor: - High flatness of the workpiece - Possibility of heating or cooling sections - No compressed air necessary - Available in different lengths - Customizable according to customer specifications

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

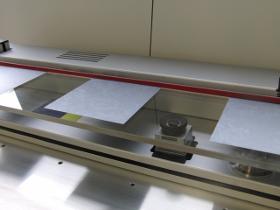

The LinearLevi-Inspectionmodule enables the inspection of substrates during the contactless transport. It is possible to check the quality of battery cells, foils, packaging, as well as wafers and chips without interrupting the transfer process. There is the opportunity to subsequently sort the substrates according to the inspection results. The application can be delivered in different versions. For example, combinations with the UltraLevi-Desk for contactless transport are possible. Features of the LinearLevi-Inspectionmodule: - Extendable - Various sizes - No particles due to no air turbulence - Double-sided inspection possible - High flatness, also for flexible substrates - Customizable according to customer specifications

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

With the LinearOverhead-Transportsystem it is possible to lift and transport sensitive materials contact-free from above. The LinearOverhead-Transport-System uses negative pressure together with ultrasound, which enables contactless linear transport of components on the top side. With this system, the workpieces can be lifted from above and guided along defined lines. Besides the linear transport, the topside conveyor can be combined with other systems to provide inspecting and sorting, as well as singulation of the substrate. Features of the LinearOverhead-Transportsystem: - Contactless overhead lifting - No damage of the substrate - No air turbulences - Available in different lengths - Customizable according to customer specifications

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

The modular Waferhandling-System facilitates all possible handling processes of wafers. Loading and unloading, conveying, gripping, inspecting, sorting and singulating can be realized in one system. Our Ultrasonic Suspension Technology keeps the wafer on distance the whole time and therefore prevents micro-scratches and contamination. Features of the Modular Waferhandling-System: - Modular Design - Contactless transport - Customizable according to customer specifcations - Linking various processes in one system

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZS-HANDLING TECHNOLOGIES GMBH

Germany

With the RobotOverhead-Gripper it is possible to lift sensitive materials contactless from above by means of a robot. Besides from gripping, it can be used for (un)loading, sorting and singulating. The RobotOverhead-Gripper uses a combination of negative pressure and the Ultrasonic Suspension Technology to enable topside gripping of the workpiece. The substrate is kept at a distance, which enables contactless transport and prevents micro-scratches and contamination. Our technology allows a high flatness of the substrate during the handling process. The RobotOverhead-Gripper is suitable for battery cells, glasses, foils, lenses, packaging, wafers and other sensitive materials. It can be supplied in various versions, for example for the contactless transport of glass components in the manufacture of flat screens. Features of the RobotOverhead-Gripper: - Contactless topside gripping - High flatness of the substrate - Different dimensions - Safety hooks can be fitted as an option

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

With the Levi RollToRoll-Transport Lines it is possible to lift, redirect and transport sensitive and flexible glass, foils and packaging. Our technology generates a thin air film between the substrate and the surface of the roll, which allows the contactless roll-to-roll transport of workpieces. Therefore, micro-scratches and contamination can be prevented. The application can be delivered in different versions. For example, combinations with the UltraLevi-Desk for contactless transport are possible. The system also allows the inspection of substrates. Features of the LeviRoll: - Contactless transport - Different lengths available - Adjustable web tension - Customizable according to customer specifications, for example with inspection systems

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

With the UltraLevi-Desk it is possible to transport and (un)load substrates without contact. Our patented technology makes the workpieces float on the surface of the ultrasonic table. The substrate is kept at a distance, which prevents micro-scratches and other damage. By avoiding compressed air and thus air turbulence, particle contamination can also be prevented. Furthermore, high flatness of the substrate is guaranteed, also for flexible materials. The UltraLevi-Desk can be combined with other systems and can be realized with or without additional drive. Features of the UltraLevi-Desk: - No damage or particles - High Flatness of the substrate - Extendable - Recesses for inspection systems or cutting units - Customizable according to customer specifications

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

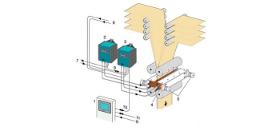

The POWERTACK electrostatic ribbon tacking system is used in the folders of heatset web offset and publication gravure printing presses. Their task is to electrostatically block the incoming paper ribbons to prevent dog ears. This is a standard feature for new presses and available for retrofitting on all common heatset presses of the world. High voltage generators generate positive and negative high voltage which is passed on to the charging bars mounted in the folder. The positive and negative bars are arranged opposite each other. The ribbons pass between them. The resulting force causes the paper ribbons to attract each other, the air in between is displaced and the ribbons are pressed against each other. As a result, the press can run at a higher speed with better folder accuracy.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

AMZ stands for automated material loading. AMZ enables automated loading of metal bars into our punching machines. Different materials types (thickness/width) can be processed successively. This only requires a short manual intervention when changing the type of metal bars, which allows for an ideal preparation of the production process. As soon as the machine has been started, the operator no longer needs to deal with feeding in the material, and can sort and further process the production parts during this time. The AMZ can also be seen as a small intermediate storage facility.

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

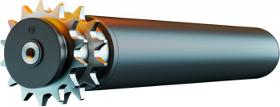

Traporol driven rollers are available in different versions depending on the type of drive. Whether single or double chain sprocket, drive via bead and dual bead or tooth belt drive. At Traporol you will find just the right solution for every application. This is how your intralogistics runs smoothly – regardless of the size and weight of the conveyed goods. Decisive criteria when choosing driven rollers are the weight and condition of the conveyed goods. In particular, conveying pallets and containers requires especially robust rollers, with a galvanized steel surface, for example.

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

Conveyor rollers made off — Plastic (with steel balls or stainless steel balls) — Steel, galvanized (with steel balls) Roller diameter: 48 mm For axis diameter: 6 mm, 8 mm

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

For different pipes ø: 50-108 mm - Outside ø: 70-150 mm Guide discs made of galvanized sheet steel. Example of appication: Two-piece with clamping screws. For guiding pallets on roller conveyors.

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

The TransiTec discharge and metering device type DZR is a flat-bottom discharge device which is placed under cylindrical hoppers. The scraper arms provide for the flow of material and the continious feed of the dosing device(s) underneath. The discharge unit DZR can be installed under bag unloading stations as well as under container emptying stations, big bag emptying stations or buffer hopper. This discharge device for poor flowing and bridbuilding bulk materials consists of a cylindrical hopper with welded or boltet flat bottom. The cylindrical hopper ensures that the product flows evenly. An over the flat bottom rotating scraper, driven by geared motor, ensures a constant filling of the underlying dosing device or other aggregate (conveyor, screw, rotary valve, etc.).

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

This device consists of a hopper with an horizontally (or sometimes inclined) scraper, which avoids bridge building. At the bottom of the hopper, a metering device takes charge of the product and conveys it.

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

The TransiTec Big Bag filling stations are suitable as standard for filling big bags with a capacity of up to 2 tons. Various options are available to meet the required task. Also a calibratable weighing of the filled Big-Bas. The Big-Bag filling station offers a variety of options: - height-adjustable suspension frame - Tightening of the big bag by means of linear drive - Double big bag filling - vibration table for compacting the products, etc., ... to name just a few.

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

Our big bag emptying stations are generally designed for big bags with a capacity up to 2 tons. Different alternatives and options are available to meet customer’s requirements. In case of a big bag emptying station for bad flowing products, we can provide a vibrating frame as well as a massaging system with pneumatically operated cylinders to enhance the discharge (or a combination of both systems in the worst case). The design of this station will allways depend of the characteristics of the product which has to be discharged. The big bag emptying station is provided with a lifting frame, adjustable in height, with automatic big bag tension device which allows a completely emptying of the bag. How it works: by loosing weight during emptying, the big bag will be tensioned automatically by a telescoping spring system. Optionally, we offer the possibility to shut even partially filled big bags.

Request for a quoteResults for

Handling%20-%20machines%20%20&%20%20equipment - Import exportNumber of results

36 ProductsCountries