- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- linear motor modules

Results for

Linear motor modules - Import export

IGUS® GMBH

Germany

drylin® SAW-1040 linear module, drylin® W aluminium profile, surface: hard-anodised, Trapezoidal lead screw TR10x2, machined lead screw end 69x15mm, guide carriage, aluminium shaft end support. Stroke length: 500mm, carriage length: 69mm, NEMA23 stepper motor with JST connector. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

IGUS® GMBH

Germany

ZLN miniature toothed belt axis based on the low-profile guide system drylin® N. System width 40mm, installation height 28mm. Ready-to-install system with stepper motors or BLDC/DC motors. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

IGUS® GMBH

Germany

The drive technology online configurator gives you the right drive technology system after you enter your requirements. You also have the option of requesting or ordering motors and other accessories, such as the motor control system. - Fast and easy configuration - Optional accessories - Detailed parts list - Fast delivery

Request for a quote

FRANKE GMBH

Germany

Franke linear modules type FTD are light, compact and ready-to-install positioning units. They are extremely compact and combine the guide system and toothed belt drive within the housing. Franke FTD linear modules can be used universally. They are suitable for long stroke lengths of up to 7 meters.

Request for a quote

FRANKE GMBH

Germany

Franke FTC linear modules are light, compact and ready-to-install positioning units. The external guide system is moved by an internal spindle or toothed belt drive. Franke FTC linear modules are very versatile. The guide cassette can be designed to meet customer specific requirements.

Request for a quote

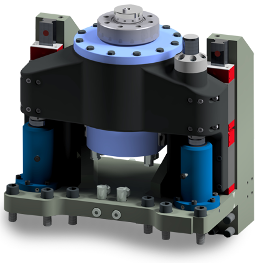

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Linear motor modules - Import exportNumber of results

6 ProductsCountries