- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- control panels - electric

Results for

Control panels - electric - Import export

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Control Panels for electrical process heaters OhmEx has extensive experience in the design of heater control systems and requirements for ‘load splitting’. Loads can also be divided into stages to give thyristor control and in addition combinations of thyristor and contactor control can be supplied to provide a fully synchronised system and limit impact on the power generating system. We can recommend cost-effective solutions to clients, outline requirements, or work to detailed specifications. In-house design facilities are supported by experienced engineers, backed-up by modern CAD facilities. OhmEx adopts an integrated project management approach to each contract, which provides effective co-ordination of design, procurement, manufacture, test and, where required, commissioning. Attention is paid to ensuring that each system is built to the demanding standards of our client, the environment and current legislation. Each control system is fully function-tested for correct operation, as a standard. Each test is simulated using the correct type of input signals to avoid start up and commissioning problems. A range of temperature control systems suitable for anything from small space heating systems to large process heating systems, including full PID control can be offered.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We are your reliable partner for the realisation of your products - from the initial idea to series production and beyond. Our goal is to offer you a comprehensive full service and to manufacture your products economically and in the highest quality. We support you in the consultative development of your early concepts and prepare an initial cost estimate in the concept phase. In addition, we accompany you during series and mass production with our long-standing manufacturing partners in the Far East and ensure reliable logistical handling.

Request for a quote

BERNSTEIN AG

Germany

The CC-3000 light-duty operating enclosure is particularly suitable for encapsulating operator control panels, industrial computers and display components and, thanks to its modular concept, can be simply adapted to versions tailored to specific customer requirements. — Customised solutions to your specifications — Monitor-based industrial design — Freely selectable width and height (max. 600 x 600 mm) — Depths from 120 mm up to max. 255 mm — High-quality extruded aluminium sections (naturally anodised) — Customised colours from RAL range — Five possible enclosure designs — Optimum heat dissipation due to aluminium sections — Front panels internally-mounted or externally-mounted — Protection class IP65 — Screw-fixed or hinged rear panel — Internal grooves for fixing components — Extensive range of accessories

Request for a quote

BERNSTEIN AG

Germany

The aluminium control enclosure CC-5000 neXt offers a unique design with a number of accessories such as the status light. The rounded contours ensure the enclosure is highly recognisable in machinery and mechanical engineering applications. — Customised solutions to your specifications — Innovative and modern industrial design — Freely selectable width and height (max. 1.000 x 1.000 mm) — Depths from 75 mm up to max. 370 mm — Rounded edges, no risk of physical injury — High-quality extruded aluminium sections (naturally anodised) — Customised colours from RAL range — Optimum heat dissipation due to aluminium sections — Integrated recessed grips for simple handling — Protection class IP65 — Internally-mounted front panel — Door configurations for direct access to the interior — Slimline design for configuring flat screen systems

Request for a quote

BERNSTEIN AG

Germany

The CC-4000 / CC-4000 SL are modular aluminium control enclosure systems. With their outstanding technical features, the enclosures simply and efficiently encapsulate industrial controllers and operator control panels for centralised and decentralised automation in production processes. — Customised solutions to your specifications — Simple and modern industrial design — Freely selectable width and height (max. 800 x 800 mm) — Depths from 52 mm up to max. 646 mm — High-quality extruded aluminium sections (naturally anodised) — Coloured areas that emphasize the design — Optimum heat dissipation due to aluminium sections — Integrated handle elements with vertical section — Protection class IP65 — Front panels internally-mounted or externally-mounted — Internal grooves for fixing components — Product features SL (in addition to CC-4000) - Two enclosure depths (55 und 99 mm) - Slimline design - For encapsulating flat IPCs

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CHRIST ELECTRONIC SYSTEMS GMBH

Germany

Your advantages of the Industrial Front Panel at a glance: Various display diagonals from 7 to 21.5 inches 13.3 to 21.5 inches in Full HD Performance classes from monitor to powerful Touch Panel PC Interface extensions and memory upgrades enable custom configuration Uniform form factor intelligence is compactly integrated into the back cover Connection to Ethernet based rock bus systems through expansion card Use of the latest touch controller Development and production in Germany Image and BIOS customization for Windows and Linux if required New, modern and functional design Retrofit in the field possible

Request for a quote

CHRIST ELECTRONIC SYSTEMS GMBH

Germany

Advantages of the Touch Panel Industrial VESA at a glance: Numerous display diagonals from 7 to 24 inches 13.3 to 24 inches in full HD Numerous performance classes from monitor to powerful Touch Panel PC Individual configuration through interface extensions and memory upgrades Intelligence is compactly integrated in the back cover with a consistent form factor Connection to different fieldbus systems through expansion card Protection up to IP65 Use of the latest touch controller Development and production in Germany Image and BIOS customization for Windows and Linux New, modern design Individual color design of the back cover, matching the machine design Retrofitting in the field possible

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 1800 is a fully automated foil application and sealing machine, suitable for plastic, tin or glass containers. mobile base frame feed conveyor with feed control synchronised star wheel stand with receptacles for the containers as form parts adjustable outer ring for guiding containers through the machine sequence foil magazine for stackable pre-cut Ballerstaedt seals pneumatically driven foil dispenser with a precise, maintenance free 180° reverse gear for removing the seals from the magazine, applying them to the sealing edge and fixing them with a pre-sealer sealing station for closing the containers with regulation of the sealing temperature, pressure and time for optimal setting of the seal parameters, conductive, optional also inductive exit conveyor for the containers central height adjustment of the magazine plate to adjust it to the respective container height all-over protective coating control panel with electrical supply unit

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 1800 is a fully automated foil application and sealing machine, suitable for plastic, tin or glass containers. • mobile base frame • feed conveyor with feed control • synchronised star wheel stand with receptacles for the containers as form parts • adjustable outer ring for guiding containers through the machine sequence • foil magazine for stackable pre-cut Ballerstaedt seals • pneumatically driven foil dispenser with a precise, maintenance free 180° reverse gear for removing the seals from the magazine, applying them to the sealing edge and fixing them with a pre-sealer • sealing station for closing the containers with regulation of the sealing temperature, pressure and time for optimal setting of the seal parameters, conductive, optional also inductive • exit conveyor for the containers • central height adjustment of the magazine plate to adjust it to the respective container height • all-over protective coating • control panel with electrical supply unit

Request for a quote

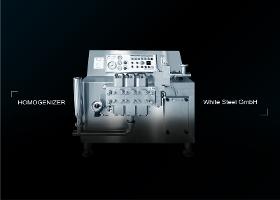

WHITE STEEL GMBH

Germany

1 to 3 molding heads Double Spindle Design For gentle products transport Diaphragm adjustable from 10mm. up to 9cm CIP System A vacuum equipped to avoid production interruption or product damage. Conical Feeding system Productivity starts from 8000 pcs/hr. up to 24000 pcs/hr Easy to use electric control panel Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

Permanently mixing Substances in a liquid Capacity from 16 to 16000 gph Compact design It is A3 certified and is electrically pre=disposed for ULCSA Pre-tested for quality control and stress test Manual Electric control panel 3 steps treatment for more product stability during subsequent treatments and storage Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Usually used for mayonnaise, ketchup, dairy product, milk and more… Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Permanently mixing Substances in a liquid Capacity from 16 to 16000 gph Compact design It is A3 certified and is electrically pre=disposed for ULCSA Pretested for quality control and stress test Manual Electric control panel 3 steps treatment for more product stability during subsequent treatments and storage Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple Viscosity types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 1 to 3 molding heads Double Spindle Design For gentle products transport Diaphragm adjustable from 10mm. up to 9cm CIP System A vacuum equipped to avoid production interruption or product damage. Conical Feeding system Productivity starts from 8000 pcs/hr. up to 24000 pcs/hr Easy to use electric control panel Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quoteResults for

Control panels - electric - Import exportNumber of results

14 ProductsCountries

Company type