- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- custom work

Results for

Custom work - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

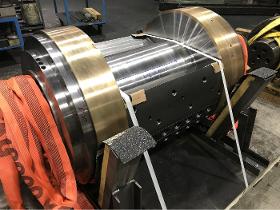

These are the parts used in mechanical shaft.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

We have been manufacturing UP machines / components and beam delivery systems for over 20 years.Benefit from our experience and let us do your demanding assembly or adjustment work.Assembly / adjustment of optical systemsAssembly / adjustment of mechanical precision systems.cleaning.Clean room assembly.Functional test.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

We manufacture a large number of standard products as well as customer-specific special parts with optical surface qualities as contract manufacturing. You are welcome to get an overview in the category metal optics.You can also download all metal optics directly from our general overview or find them in our download area .In addition to such components with an optical function, we also manufacture precision parts for which a high geometric accuracy is in the foreground, such as air bearing components or micro-milled parts. With an extensive inventory of ultra-precision machines and the corresponding measuring technology, we manufacture with accuracies down to the sub-micrometer range and with roughness up to approx. 1 nm [Ra]. LT Ultra serves both single and series production. We look forward to your inquiry.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Special mechanical engineering - unique, individual, tailored For the plant, machine and special machine engineering sector, we manufacture ■ custom-made components ■ casings and coverings ■ machinery racks ■ noise-protection cabins ■ complete assemblies Thanks to our vertical integration combined with a large material storages, we are realizing shortest throughput time for your projects on highest quality level. We serve numerous sectors like the rubber industrie, steel processing industry, automation technology, consumer goods industry, energy industry and any other branches where individual steel, stainles steel and aluminium components and assemblies are needed. Whether you want custom-made components or ready mounted and suface-finished overall systems, we do it for you!

Request for a quote

ING. KURT SCHADE GMBH & CO. KG

Germany

Our steel construction is certified according to the current standards DIN EN 1090-2 and DIN EN 3834-2. We manufacture welded parts, welded constructions and welded assemblies up to execution class 3 (EXC3). Steel construction components such as: - Assembly devices for aircraft or automobile construction - Machine frames for compressor construction - Welded frames such as track systems and transfer tables - High-precision vacuum clamping plates for high-pressure presses - Complete rudder systems We produce both: individual components and small series. Do you have any questions about our techniques, capacities or prices? Contact us, we will be happy to give you direct information.

Request for a quote

ING. KURT SCHADE GMBH & CO. KG

Germany

With our modern CNC boring machines, CNC milling machines and CNC lathes we work on steel construction components and process forgings and castings into precision components for mechanical engineering. Our cutting machine operators work precise on parts that are up to 10 meter long and weigh 25 t - with an accuracy of 0.01 millimeters. This is how customized mechanical engineering elements are created, such as: - wind power components - press stand - gear housing for mining ... The machining technicians create the individual CNC programs together with our CAD specialists directly on the CNC machines. An integrated management system and the uniform control concept from Heidenhain guarantee a high degree of flexibility; all CNC machines for heavy-duty machining are networked and access a central data pool. This is how we guarantee you fast programming and set-up times, absolute repeatability and adherence to schedules.

Request for a quote

ING. KURT SCHADE GMBH & CO. KG

Germany

Our many years of experience in the fields of steel construction and CNC machining also make us a competent service provider in the field of repairs. Contact us – together we will find the optimal solution!

Request for a quote

ING. KURT SCHADE GMBH & CO. KG

Germany

With the complete assembly of assemblies, we offer you an all-round package: - We buy all the materials you need. - We straighten, staple and MIG MAG weld the individual steel construction components exactly according to your specifications and complete the components using high-precision CNC machining. - We assemble the finished, repeatedly tested components in our 2000 square meter assembly hall according to your construction plans into ready-to-install modules. - We check the final assembly down to the smallest detail. - We deliver the finished end product to you. Are you looking for a reliable service provider to implement your next project? We look forward to your inquiry.

Request for a quote

PRESSTA EISELE GMBH

Germany

Punch tools to work aluminium profiles Customized Production Single or Chain tools Holes, notches, bending Tool size up to 1.200 mm Power up to 800 KN

Request for a quote

XIMEA GMBH

Germany

We design for performance! When it comes to custom engineering we work with you as a team in close collaboration. That is before, during, and after the job is done. If you aim to develop your project further we are always eager to assist you with a creative, rapid, and highly efficient OEM-design. Starting from scratch or using any existing XIMEA product as a seed, we provide services all the way up to full custom developments and manufacturing.

Request for a quote

TECHNO-COMPOSITES DOMINE GMBH

Germany

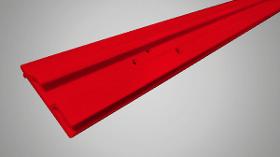

roller shutter housing connector We worked with a customer from the construction sector to develop a GRP connecting element that optimally connects the window frame and window blind box. This transfers the high mechanical loads exerted by wind in an optimal way. At the same time, the GRP profile improves the insulation capability of the entire system. The GRP profiles are drilled and counterbored on a large scale using a CNC machine, thus making installation significantly easier for the workmen.

Request for a quote

TECHNO-COMPOSITES DOMINE GMBH

Germany

Radome antennae TC is working with the customer to develop suitable solutions for antenna systems. This ranges from small batches all the way up to largescale production, naturally including the necessary mounting and connecting parts such as cover components with cable bushing, brackets for mobile phone masts, etc. The parts are processed on our highprecision 5axis CNC machinery.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

With state-of-the-art can sheet production lines and recycling centers in North America, South America, Europe and Asia, Novelis serves the most recognizable brands including Coca-Cola, Crown, Ball Corporation, Ardagh Group and ABInBev. Beverage cans are, and will remain, the core of Novelis’ product portfolio. Working alongside our customers, we innovate to meet the ever-evolving preferences of consumers, whether for new shapes and sizes, alternative coatings or more. For example, Novelis is working closely with customers to develop and produce distinctive aluminum bottles, which offer the same portability, light weight and recyclability as aluminum cans, but with the added benefit of being re-closeable. In addition, Novelis is also working on technology to support our customers seeking to meet consumer demand for sustainable packaging for new beverage categories.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

cryogenic decoating of big-sized parts Take advantage from our experience! We offer customized solutions for: ■ decoating of big-sized parts (e.g. vulcanized metal housings, tools, etc) ■ devices for metal shringking-work The individuel customized solution will be performed according to customer specification!

Request for a quote

WEBER ULTRASONICS AG

Germany

Weber manufactures the work piece fixture custom-specific based on CAD-files or original work pieces. We use materials like resin, steel, aluminum or brass. Special features like clamping or ejectors etc. are possible.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Removal of loose oxide and electrode-erosion residues, dust deposits or creepage currents which cause soiling in moving contact areas such as motor-vehicle ignition distributors, relay contacts, resistance or potentiometer slideways, in static contact areas such as motor-vehicle spark plugs, plug-in connections, sliding and screw connections, in or on electrical and electronic equipment or devices of all kinds Advantages and benefits Highly effective due to outstanding cleaning properties Broad range of uses for all maintenance and customer service work in electrical sector Fast evaporation after striking surface

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

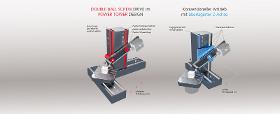

“The deflection (∆) of the tool tip (TCP) due to the machining force (F) depends to the third power ( l 3 ) of the length ( l ) of the distance TCP to the front bearing axis (A), in relation to the bending stiffness (E · I) “ Or: the shorter l , the smaller ∆ and the higher the precision

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SAMAG MACHINE TOOLS GMBH

Germany

PENDULUM CHANGER – GOOD FROM EXPERIENCE. The W-axis principle, established by SAMAG since 1995, enables workpiece loading to be carried out parallel to production times. The workpiece carrier table is moved in the swivel drive from 0 – 180°. This means that the next loading and unloading of workpieces can take place during processing. Efficient and useful also for robot-assisted loading.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

DIVERSE TASKS REQUIRE FLEXIBLE MACHINE CONCEPTS, SPECIAL QUESTIONS REQUIRE INDIVIDUAL SOLUTIONS AND EFFICIENT PRODUCTION REQUIRES SECURE PROCESS CHAINS, IN SHORT: TFZ – FIT 2 TASK! With the very successful and established TFZ series, SAMAG has been a guarantee for task-specific solutions and tailor-made machines for years. At the same time, the well-thought-out machine structure of the TFZ enables optimal deep drilling and highly dynamic milling with just one clamping and thus efficiency par excellence. The unique design principle always ensures optimal accessibility, a minimally short distance between the swivel bearing and the processing point and extremely stable tool guidance for high-precision work, even when high lateral forces occur. No matter where you set your priorities in the manufacturing process, we are able to technologically align our TFZ machine accordingly and you can rely on “your” TFZ solution to fit perfectly, today and in the future.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

4 SIZES AND LOTS OF POSSIBILITIES! THE SFZ SERIES ESPECIALLY SCORES WITH STRONG PERFORMANCE. Starting from the four basic models of the SFZ series; We offer modular equipment variants, depending on performance requirements. Completely in the spirit of FIT 2 TASK. In order to guarantee individual performance, the SFZ machines are equipped with the latest generation of Heidenhain iTNC640 controls as standard. SIEMENS 840D SL is optionally available as an alternative, depending on your requirements.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

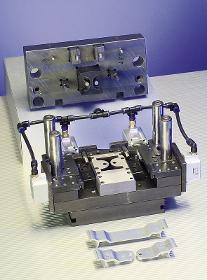

CLAMPING DEVICES FROM THE EXPERTS. SAMAG OFFERS PROCESS-OPTIMIZED SOLUTIONS AND A COMPLETE ALL-ROUND SERVICE WHEN IT COMES TO DEVICE CONSTRUCTION. Complete machining of workpieces begins with the right clamping concept. Our engineers develop innovative solutions and clamping devices at the highest technical level. Processing complicated workpieces in efficient cycle times requires process-optimized clamping. We deliver technological solutions with longevity and all-round service. The workpieces are aligned, fixed and clamped hydraulically, pneumatically or mechanically. If several parts are processed at the same time, depending on the number of motor spindles, high-precision fixing, positioning and clamping of the parts is necessary. This is only possible with automated tensioning (e.g. hydraulic) and precise alignment of the devices.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center, year of construction: 2008 Product name: MFZ 2-2 Update Used 2-spindle horizontal 5-axis machining center Year of construction: 2008 Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (machine without coolant system and accessories) X-axis travel: 450 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 450 mm Rapid traverse XY Z axis 60,000mm/min 2 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm Spindle distance 450mm Chip conveyor Knoll (scratch belt conveyor in positioning variant across the machine) High-quality Knoll KSS system with fine filtration Flush gun Complete enclosure Tool storage (2 x 50 tools) Operating voltage 400V 3N ~ Control voltage 24V DC Connection value machine approx. 72 KVA Compressed air connection 6 bar

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center, year of construction: 2006, extensive manufacturer overhaul in 2021 Product name: MFZ 2-2 Update Used 2-spindle horizontal 5-axis machining center Year of construction: 2006 Extensive manufacturer overhaul 2021 Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (machine without coolant system and accessories) X-axis travel: 450 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 450 mm Rapid traverse XY Z axis 60,000mm/min 2 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm KSM rotary union with electronic leakage monitoring Chip conveyor Knoll (scraper belt conveyor in positioning variant along the machine, ejection height 1,200mm)

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

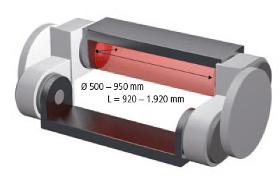

THE MULTI-SPINDLE SHAFT DRILLING MACHINES OF THE TBM roto series ARE DESIGNED FOR PERMANENT PRODUCTION USE. THEY ARE PARTICULARLY DURABLE, EXTREMELY ROBUST AND GUARANTEE THE HIGHEST PRECISION: 24/7/365! TBM roto – shaft drilling machine for production For machining rotationally symmetrical workpieces such as gear shafts, camshafts, steering rods, common rails, standard parts... Customer-specific solutions, automation, handling, workpiece clamping, workpiece cleaning… Long-lasting machines for parts with the highest precision Additional units, features or modules available Optimized accessibility to all components for maintenance and service

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Robust, long-lasting machine for individual part and small series production Very good accessibility to the processing unit and to the workpiece clamping Crane loading possible Up to 3 mobile tool rests Service and maintenance-optimized accessibility to all machine components Crane hook machine, therefore short set-up times OUR TBM mono IS THE SPECIALIST FOR INDIVIDUAL PARTS AND SMALL SERIES. SPECIAL FEATURES: VERY SMALL DRILLING DIAMETERS WITH A LARGE DRILLING DEPTH AT THE SAME TIME

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

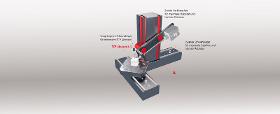

The particularly short distance of the unique DOUBLE BALL SCREW DRIVE from SAMAG increases the rigidity and thus the machining accuracy immensely. Compared to traditional drive concepts, the TFZ concept is up to 27 times stiffer and more precise. Reduction of vibrations on the drilling and milling unit through DOUBLE BALL SCREW DRIVE and POWER TOWER DESIGN, this is how it works: Second ball screw with additional guide and second pivot bearing on the rear rail (V) Upstream double-guided and particularly strong ball screw drive of the X-axis Minimum distance (l) between tool tip (TCP) and front swivel bearing (A) 1-spindle concept guarantees short, stable tools with excellent accessibility to the workpiece and the machining point Generously sized work spindle to achieve maximum performance parameters Stiff milling spindle with additional, patented support Variable steady rest positioning system to increase drilling accuracy with spacer between spindle and steady rests

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

QUICK CHECK GUN DRILL Eight basic cycles, based on experience, are included in the scope of delivery of the machine and guarantee professional processing of the workpiece. Specific groups for cross drilling cycles are available as an option. This makes workshop programming and programming of crossing holes easier by adapting the feed when hitting the cross hole. This increases the tool life significantly.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

STABILITY AND HIGHEST PRECISION COME BY APPROXIMATE. THE PERFECTLY THOUGHTFUL AXIS CONCEPT IN THE POWER TOWER DESIGN ALLOWS MINIMAL TCP DISTANCE AND MAXIMUM MACHINE STIFFNESS. The POWER TOWER DESIGN impresses with its compact design and extreme rigidity. All components in the force flow are statically and dynamically optimized down to the last detail, thus ensuring perfect work results. The clear separation of all linear axes guarantees long-term dimensional accuracy of all axis drives and sustainably prevents tolerances from overlapping and thereby increasing. Thanks to the large footprint of the Y-tower and the unique DOUBLE BALL SCREW DRIVE, we always achieve optimal support for the drill beam in the TFZ and at the same time an extremely short distance between the swivel bearing and the tool center point (TCP distance), for maximum rigidity with large transverse forces.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

TBM flex – special deep drilling and milling centers – deep drilling and milling in one machine Modular system for drilling and milling For individual part and small series production Peeling and rolling possible Processing of forklift forks, telescopic forks, aircraft landing gear parts, special screws, special cylinders.

Request for a quoteResults for

Custom work - Import exportNumber of results

116 ProductsCountries

Company type

Category

- Mechanical engineering - custom work (100)

- Cables, high-voltage (5)

- Wood veneer - machinery and equipment (3)

- Manometers (2)

- Cameras, cinematographic (1)

- Mechanical transmission - components (1)

- Metal joinery, wrought-iron - machinery and equipment (1)

- Paper - manufacturing machinery (1)

- Profiled sheets - ferrous metal (1)

- Radio and television broadcasting - equipment and systems (1)

- Rubber - industrial machinery and equipment (1)

- Silicones (1)

- Tins and cans (1)