- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heaters

Results for

Heaters - Import export

A.B.C. WORLDWIDE GMBH

Germany

Terrace Heater Ecoline available in stainess steel or steel powdercoated Up to 76 hours operating time burning systems are free adjustable radiates heat within a radius of ø 4,5 m wheels included european gas pressure regulator included

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

Cable Type Heaters have initially been developed and used for the safe operation in fertilizer plants. However nowadays, they cover a large range of applications due to their modular construction and minimum space requirements. They are suitable for heating up nearly all gases and liquids or superheating steam. They are mainly used in hazardous areas. Especially when processes require a combination of high power (in the MW range) high pressure and temperatures of up to 550°C cable type heaters are the means to choose.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

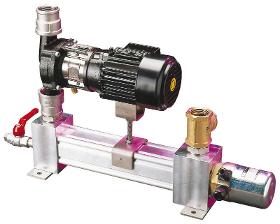

CSN® PreHeater consists of one or more CSN® Flow Heaters, which are equipped with a valve and a pump, as well as standalone controller.Combustion engines requiring immediate operational readiness must be preheated before starting. The wellknown cold start problems are eliminated and the engine can be operated at full load from the beginning. Furthermore, cold start wear is considerably reduced. Typical fields of application for this type of preheater units are e.g. emergency power units (Diesel engine + generator) or locomotives and ships (Diesel engine for propulsion).Combustion engines requiring immediate operational readiness must be preheated before starting. The wellknown cold start problems are eliminated and the engine can be operated at full load from the beginning. Furthermore, cold start wear is considerably reduced.

Request for a quote

EMBRO GMBH

Germany

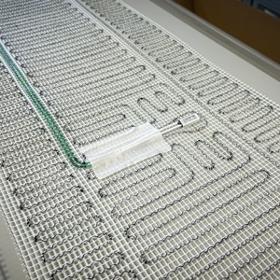

In order to meet the demands for robustness and efficient heat output, we have embroidered the heating element on a glass mesh fabric carrier material. Between the meandering arrangement of the heating strands, we integrate a recess for the temperature switch in the CAD layout. In addition, a second wire is laid concurrently as a PTC thermistor for the electrical connection of the safety switch. After the technical embroidery process, the safety switch is inserted and connected by our company’s respective department. Each prefabricated element is tested for functionality and performance in the final inspection and is delivered to the customer after passing the test. As a semi-finished product, the infrared heating element on glass mesh fabric can be further processed by the customer, e.g. in connection with silicone, rubber or epoxy resin.

Request for a quote

EMBRO GMBH

Germany

Aramid fibers are suitable for very demanding applications and they are widely used in the firefighting industry (manufacturing of firefighters’ clothing) because of their flame retardant properties. Aramid is not only fireproof, the aramid fibers also have a high tensile strength, which is why they are often used for bulletproof vests (military and police) or for armoring selected emergency vehicles. A special property of aramid nonwovens is its good thermal insulation. The laid heating wire creates a very high heat output, which is insulated by the nonwoven. Aramid has a high heat resistance, which is an enormous advantage since laying the heating wire generates a very high heat output which is further enhanced by the insulation provided by the aramid nonwoven carrier. In addition, the nonwoven is either not combustible or flame retardant and can be used for a temperature ranges of up to 200°C.

Request for a quote

FRIEDRICH SCHULTZE GMBH

Germany

Schultze RiRo heaters are your solution for industrial and commercial heating appliances: dust- and watertight, corrosion-resistant, flexible and uncomplicated to install. Suitable for damp locations and rough industry environment, for reliable and efficient heating – often unnoticed, but indispensable. The heating power is steplessly adjustable and the thermostat keeps your chosen temperature constant. Choose either frost protection or your temperature between + 5°C and + 30°C. The red signalling light shows when power is on.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Screw-in Tubular Heaters are the standard solution for all heating processes with liquids or gas. The heater is installed in a tank or a tube system by the G1½" screw fitting. The IP54 connection head, fitting and tubular heater consists of stainless steel. The tube sheath material 1.4529 is resistant to sulphite, phosphors and hydrochloride media.

Request for a quote

FRIEDR. FREEK GMBH

Germany

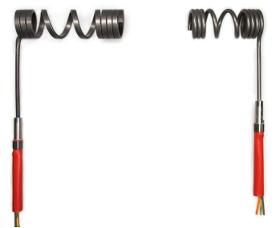

HotCoils have a larger cross-sectional area and are thus capable of greater power than MicroCoils. For this reason they are used in hot runners with adequate space and where high heat densities are required. Owing to the large number of variants and for cost reasons, the sheath material for HotCoils is stainless steel - the standard for the market and thus also for Freek. HotCoils are large enough that thermocouples can be integrated into them. Our standard here is Type J (Fe-CuNi; red/blue), while Types J and K are also available conforming to the IEC and ANSI standards (see colour codes). Since the measurement point of a built-in temperature sensor is situated in the heater and never where the heat is actually required, a HotCoil with a thermocouple makes particular sense where the application allows the use of larger processing (temperature) windows or where the installation location or the design requires protection against overheating.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The Freek heat transfer nozzle heating system especially addresses manufacturers and users who operated their hotrunner nozzles with cast-in heaters in the past and would like to stick to their engineering know-how without paying the high price of this former heater design. The standard material of our Freek heat transfer nozzle heater alternative is brass, with or without coating, preferably with a slit. The slit allows the assembly of an external bendable thermocouple and facilitates the disassembly, e.g. in case of a revision and can be coiled over. This is not possible at competitor's nozzle heater solutions. Freek's tight coiling at the heater's ends provides a maximum possible power concentration (patented).

Request for a quote

FRIEDR. FREEK GMBH

Germany

Preformed silicone heaters are useful for diamters as small as 12 mm and up to 100 mm. Rounded silicone heaters are not possible with self-adhesive foil. Spiral Wrap Pre-Formed Silicone Rubber Heaters are suitable for tubes and flexible pipes and hoses with Ø 6,35 mm (1/4"). Spiral formed flex heaters can be used up to Ø 12 mm (the length of the stretchable silicone spiral wrap heater is reduced accordingly). The thickness of our spiral-wrapped silicone strip heaters is 2,2 mm. Also our gas and pump line heaters, most frequently used in the semi-conductor process, are shaped and pre-formed according to the object geometry to be heated. They are designed to regulate temperatures in order to prevent condensation in the line. Current applications here are Semi Conductors, Vacuum Chambers, Wafer Chucks, Valves, Exhaust & Pump Systems.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Silicone heaters and Kapton heaters are preferred surface heating elements for laboratory equipment and medical technology due to their easy handling and variety of shapes. Like Kapton polyimide heating foils, silicone heaters are resistant to continuous temperatures of up to 200 °C, with self-adhesive foil up to 180 °C. When designing silicone heaters and Kapton foil heaters, the designer has almost unlimited degrees of freedom. This applies to the minimum and maximum dimensions, which are set within wide limits, as well as to contours and recesses, holes and feed-throughs of any kind. The good shape flexibility of silicone heating mats and foils as well as Kapton polyimide heaters also enables the heating of cylindrical, conical or rounded surfaces. The resistance of polyimides to fungi, bacteria, ozone, weather, ageing and most chemicals, acids and solvents is very good, making polyimide (Kapton) heaters an ideal solution for many critical applications.

Request for a quote

FRIEDR. FREEK GMBH

Germany

We offer an extensive range of drum and barrel heaters and container heaters: Heating jackets, silicone drum heaters, base drum heaters and insulating but unheated drum jackets and lids for heating and insulating plastic and metal drums respectively containers. According to the destined application we use polyester, silicone, teflon and glass fibre for our drum heaters and container heaters. Some of the materials are coated and multi-layered resp. combined. Our drum heaters can be used individually and in combination and can be ordered and delivered online (shop.freek.de) for all standard drum sizes (25 / 50 / 105 / 200 litres). Of course, we also manufacture our heating jackets, heating sleeves, base heaters and insulating bonnets individually to fit your container and your special application. HC - Heating cabinets If you heat several drums or containers together or need a container heater for the ATEX area, the heating cabinets from our partner Amarc are the right choice.

Request for a quote

EMBRO GMBH

Germany

If you are looking for a very efficient heating solution tailored to your needs that comes with competitive prices and short delivery times, please contact Embro and get the best service and high-quality products Made in Germany and Made in Europe!

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

Heating of all kinds of liquids and gases, especially suitable for installation in hazardous areas (ex. areas). Continuous heating by means of heat exchange between the tubular heating elements and the medium. We are experts in customizing process heaters always ensuring to deliver solutions which will be both technically and economically sound.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® Insulator Heaters are used in flue gas cleaning systems for preheating the insulators and as protection of the equipment against condensation and freezing during shutdown periods

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® EXPLOSIONPROOF SPACE HEATERS CSN® explosionproof space heaters are used for heating zone 1 and 2 hazardous areas. Standard devices are available in the common temperature classes T1 to T4; temperature classes T5 and T6 can be offered on request. The use of finned tubes for the CSN® explosionproof space heaters is the most economical solution for heat transfer in the field of electric heaters. By coiling corrugated helical fins on tubes of different alloys, we obtain extremely large tubes surfaces and, consequently, low temperatures on their surfaces. We use this interaction to produce explosionproof space heaters on a highquality level. CSN® explosionproof space heaters with coiled fins are intended for horizontal mounting and suitable for both wall and floor mounting (for permanent installation)

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® Explosionproof screw plug or flanged immersion heaters ( Ex ) are perfectly suited for direct heating of liquids or gas / air mixtures in hazardous areas. The devices are available with attached or integrated temperature monitoring systems. For these heaters various high quality stainless steel grades are available. The electical immersion heater type 94./..EEs….T.(.) is designed for the heating of liquids and quit gasair mixtures in the zone 1 and zone 2. The standars elements, mentioned in this list are suitable for DGRL (code 97/23/EG) Art. 3 Para. 3. The elements can be suited (on request) to other uses requiring another classification according to DGRL.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® space heaters are robust heaters for industrial environments and can be used even in harsh environments. Depending on customer’s requirements, the heaters can be manufactured with different surfaces (painted steel, galvanized/painted steel, stainless steel) and equipped with temperature controllers, temperature limiters and protective grids.factory floors crane cabs work containers workshops storage rooms Instantaneous heating on construction sites garages garden houses fire brigade equipment houses

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

Typical Fields of Application are in the chemical, petrochemical, railroad and shipbuilding industries, in the machine and industrial equipment construction. CSN® circulation heaters are manufactured in close coordination with our customers from a few watts to the megawatt range, a division in individual circuits is made according to customer’s requirements. Equipment for installation in hazardous areas we produce in protection class „Ex d“, „Ex de“, „Ex e“. On request, CSN® circulation heaters are supplied with optimized process controls. Please contact us to talk about the most appropriate control system. Schniewindt is certified by the Lloyd’s Register to produce equipment according to the Pressure Vessel Directive 2014/68/EU and a certificate from TÜV (Technical Monitoring Agency) certifies that we meet the prerequisites for welding procedures according to AD 2000 Merkblatt HP 0 / DIN EN 7293.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The Freek heat transfer nozzle heater type especially addresses manufacturers and users who operated their hotrunner nozzles with cast-in heaters in the past and would like to stick to their engineering know-how without paying the high price of this former heater design. The standard material of our patent pending Freek heat transfer alternative is brass, with or without coating, basically with a slit. Characteristics of our HotMicroCoil nozzle heaters sheathed by a reflection tube are easy mounting and variable heat distribution. Because of its direct touch and toleranced fit, the heater allows a very good heat transmission to the nozzle. In all our HotMicroCoils with reflection tube the assembly of a thermocouple is possible and recommended for bigger diameters and power. Also most common nozzle heater solutions are HotMicrocoil heating elements with clamp bands with diverse locking mechanisms.

Request for a quote

FRIEDR. FREEK GMBH

Germany

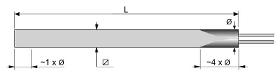

Occasionally also these terms are used for cartridge heates: heating cartridge, insertion heaters, spiral cartridge heaters. As a rule cartridge heaters consist of a cylindrical stainless steel tube and thus provide a high corrosion prevention. There is a heating wire inside which is wound onto a ceramic core. The number of coils varies depending on the power. In order to avoid a short-circuit, the cartridge heater is filled with magnesium oxide and compressed afterwards. Highly compacted they reach a surface watt density of up to 50 W/cm² and withstand highest stress. In the plastics industry cartridge heaters are used in hot runners in order to temper thermoplasts during injection moulding processes. Other areas of applications for process heat are e. g. packaging, diecasting or continuous casting in which zinc or aluminium are processed. Further applications are to be found in mechanical as well as medical and laboratory engineering.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Square cartridge heaters are used where much power has to be installed near the surface of a tool, e.g. in cutting knives, sealing stations or hot plates. With a soft, malleable condition in stainless steel or nickel sheath square cartridge heaters can easily be pressed into common milled rectangular grooves. Apart from the advantageous heat transfer over ¾ of the sheath, it is not necessary to cement or cast in the heater which is imperative for round cartridge heaters. Unlike tubular heaters which are also available in square sections (see chapter Flexible Heating Pipes), the square cartridge heaters have the termination on one side and can be loaded with 16W/cm² (2.5W/in²) due to their special inside construction.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Flexible silicone heaters are resistant to permanent temperatures up to 200°C, with self-adhesive foil 180°C should not be exceeded. Higher temperatures of 230°C are possible for a short time without destroying the heater. The temperature that will be reached within the application, generally is not easy to predict, as there are many influencing factors. In addition to the power, resp. surface load, this also includes mass and type of the material to be heated (thermal conductivity, surface quality, etc.) installation / assembly situation (bonded, vulcanised, clamped, etc.), ambient temperature, air movement and, of course, the control technology used. Application examples for silicone heater mats include: canteen kitchen technology / catering, anti-fog and anti-freeze applications, tool or plate heating in machines, 3D printers, laboratory equipment, composite materials repair, joint curing and much more.

Request for a quote

FRIEDR. FREEK GMBH

Germany

In general, a Kapton film heater is always more expensive than a silicone heater or polyester heater. Where chemical resistance or the weight of the flexible heating element plays an important role, however, Kapton heaters are the ideal solution. The resistance of Kapton Polyimide to fungi, bacteria, ozone, weather, ageing and most chemicals, acids and solvents is very good, so that heating elements made of Polyimide (Kapton) are an ideal solution for many critical applications. Kapton foil heaters are also silicone-free and are characterised by an even heat distribution. The dielectric strength of a Polyimide film is very high and so the flexible Kapton (Polyimide) heater can be very thin. Due to the small thickness, the heat transfer to the component is improved and higher surface loads are possible. Typical applications for Kapton film heaters are: Laboratory technology, aircraft electronics, printers, diagnostic instruments, vacuum chambers, medical equipment and many more.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Polyester heaters also referred to as Polyester film heaters or Polyester foil heaters consist of an electrically conductive ink between two insulating respectively carrier layers of polyester. With a maximum size of 600 x 1000 mm, their average height is only 0.2 mm. As the picture examples show, practically any shape and type of cut-out is possible. Polyester foil heaters are resistant to permanent temperatures of up to 90°C (max. 100°C for short periods). It is generally not possible to predict which temperature a Polyester heating element will reach in the application, as there are extremely many influencing factors. These include not only the power, but also the mass and type of goods to be heated, the ambient temperature, air currents, the type of mounting and, of course, the control technology. Typical applications for Polyester heaters are e.g. cup warmers in coffee machines, mirror heaters, plate heat exchangers, flat applications with a target temperature below 90°C.

Request for a quote

FRIEDR. FREEK GMBH

Germany

There are three main types of infrared emitters. They are classified according to emitted wave lengths. Which emitter type is the best for your application depends on many factors. For most applications an optimum match of emitted wave length and absorption of the target material is desirable. This means a highly efficient transfer of radiation energy in the material and thus a very quick heating. However, there are exceptions to the rule. At very high required energy densities, cyclical processes, transparent, thin or low-conductive materials it might be necessary under certain circumstances to deliberately use emitters whose characteristics deviate radically from the absorption characteristics of the material to be processed. Finally, in many applications, including thermoforming, all three basic emitter types are successfully used – long wave ceramic emitters, medium wave quartz emitters and short wave halogen emitters.

Request for a quote

FRIEDR. FREEK GMBH

Germany

IBC/A-Container Base Heaters are used for the heating of bag-in-box containers. It's a silicone heater mat that is placed below the bag before that is filled. For a faster warming, an additional unheated insulating sheath covering the four sides and the HILC unheated insulated lid can be used. The IBC/Bpro-Container heating jacket as well as the HILC unheated insulated lid are perfect means to support the IBC/A base heater. Using the base heater together with the heating jacket and the insulation cover accelerates the heating process and to reduces heat losses.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Square stainless steel tubular heaters BASE-flex (1.4541) are a reliable industry standard for the use in heating platens and manifolds. In contrast to traditional tubular heaters with a round section which have to be bent by machines, square BASE-flex can be fitted into any rectangular groove with simple hand tools. Moreover, the square shape results in a bigger heat emitting area of up to 80% compared with a corresponding round section. Finally, the easy manual mounting saves the usually high technical expenditure for casting-in / soldering / cementing of bent round tubular heaters. A soft version of the BASE-flex, the NICKEL-flex (2.4068) is available as special execution. Due to the soft, easy to form nickel material, the NICKEL-flex is suitable for manual mounting with hand tools in round sections, too. Furthermore, Nickel has a better capability to conduct heat compared with stainless steel.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Finned Tubular Heaters are the ideal solution for air or gas flow heating processes. The ribs enlarge the heat-releasing surface significantly. Basis of the finned tubular heaters are our 8.5 mm tubular heaters. The outer diameter of the fins is 28 mm. The elements can be delivered straight, U-shaped or circular (special design on request). Tubular heater as well as fins are made of stainless steel, the standard for the tube is 1.4828 (other materials possible as in chapter Round Tubular Heaters), the fins are normally made of 1.4301 (1.4571 on request).

Request for a quoteResults for

Heaters - Import exportNumber of results

188 ProductsCountries

Company type

Category

- Heating, domestic - installations and equipment (45)

- Electroheat - machines and equipment (39)

- Heating, industrial - installations and equipment (12)

- Unit heaters (10)

- Induction heating systems (10)

- Electroplating - machines (7)

- Radiators and convectors, industrial (6)

- Oiling - machines and systems (2)

- Water-heaters, domestic (1)

- Central heating systems (1)

- Control boxes - electric (1)

- Elements, electric (1)

- Storage heaters (1)

- Biomass energy - production (1)

- Boilers, cast iron (1)

- Carbon and graphite - electrical components (1)

- Cars - electrical and electronic parts and components (1)

- Energy - production plants and equipment (1)

- Engineering - industrial contractors (1)

- Explosion-proof - equipment (1)