- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- lift motor

Results for

Lift motor - Import export

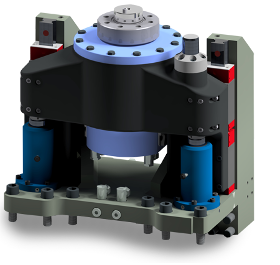

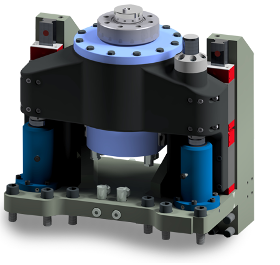

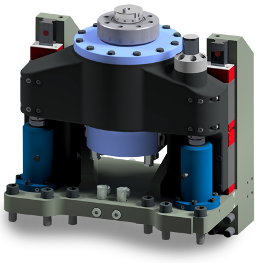

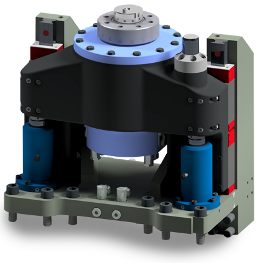

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

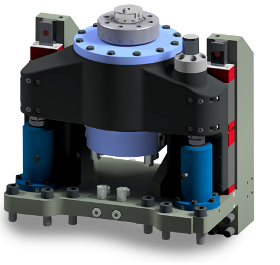

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

PRESSTA EISELE GMBH

Germany

Collects swarf and chips in a 1000 litre container can be dumped easily by fork lift. Motor-driven top opens automatically 2 hoods Ø 100mm – without pipe Powered by 4,0 kW, 400 V, 50 Hz motor Performance 4.300 m³/Std. incl. ventilating worm casing above the extractor Large filtre with big surface and external filtre shaker for long durability Steady-state performance or controlled by saw Noise level: 80 db/A Dimension 180 x 320 x 165 cm Weight 380 Kg Serial Paint: RAL 7016 / 9016

Request for a quote

TISCHKÖNIG GMBH

Germany

Melamine table top: - chipboard according to DIN 68765, melamine resin coated on both sides and 2 mm ABS edge - the table top is hygienic, it is not harmful to food, and is simple to clean High-quality frame DT30: - stable steel construction, square columns with 2 motors - 3-stage lifting system (telescopic) - dual motors - height adjustment: 62 - 127 cm (without table top) - max. speed: 35 mm/s without load - collision protection - low noise level: < 45 dB - color: polyester powder-coated - LED display with 4 memory positions - plastic glides for safe standing - level compensation up to 10 mm Selection options: - table top color - table top thickness - dimension - frame color

Request for a quote

HANSA-HOLZ-KONTOR HORST RÜCKLE GMBH & CO. KG

Germany

Frame system with 3 built-in motors tasked to adjust the head, back and foot regions to any position required within the limits. Lifting built-in motor, height adjustable by 35 cm offering the benefits of a slatted frame for nursing beds. Quiet technology. Film coated slatted frame in multi-layer birch, with 28 slats. Mounted in flexible DUO caps covering the side rails. Individually adjustable level of firmness in the centre zone. Shoulder comfort zone. Load distributing centre belt.

Request for a quote

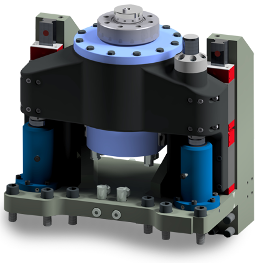

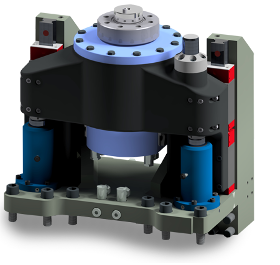

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

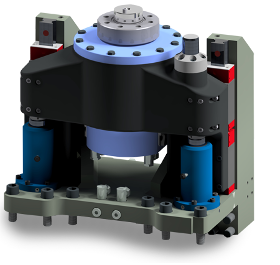

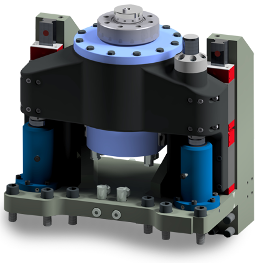

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

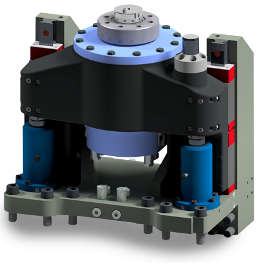

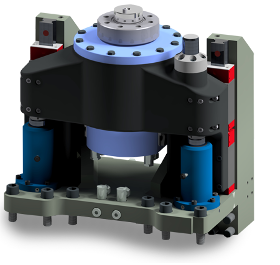

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

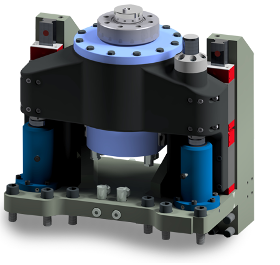

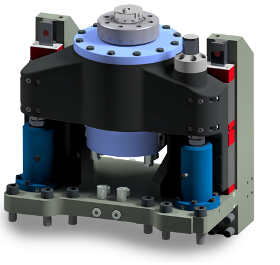

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

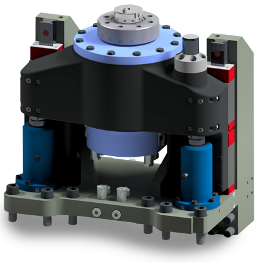

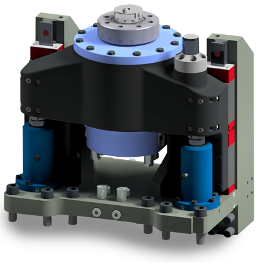

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

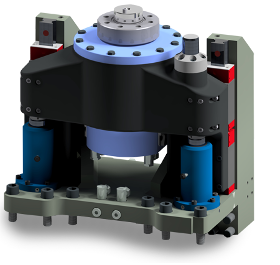

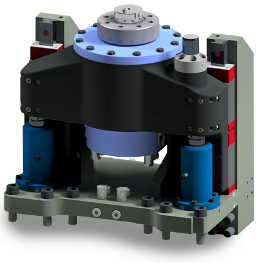

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

With our new overhead unit for AirWave1/2 you can react flexibly to new requirements in your logistics facility: No technician required for measuring No technician required for assembly Basket size 0,42m3 (75x75x75cm) Optimized for shipping Can be pushed up to the packing table from behind Only available in this dimension All components pre-assembled (incl. lift, motor control and sensor) Can be fixed to the table Can be fixed in the ground via floor mounting brackets. Can be additionally stabilized with support profiles (Delivery without AirWave air cushion machine, foundation shoe and support profile)

Request for a quote

MOSCA GMBH

Germany

• Top-mounted SoniXs ultrasonic sealing unit • Automatic height adjustment of pressure plate to bundle height • Easy accessibility • Electrically driven lift plate with geared brake motor • Strap dispenser • Siemens PLC control with touch panel • 2-column design from 2,200 mm passage width Different Models: [KZV-111] • Top-mounted sealing head • One SoniXs- sealing head and one vertical strap guide • Movable strap lance for strapping of palletized goods [KZS-111] Like basic model KZV-111, with laterally moveable turntable [KOV-111] Like basic model KZV-111, with additional underfeed channel for unpalletized goods [KVV-111] Like basic model KZV-111, bottom arch with automatically controlled strap lance or underfeed channel; particularly suitable for strapping of frequently changing package types with or without pallets Options: • Automatic balk feeder with large buffer [KOV] • Angle edge protection for securing sensitive products for transport [KOV]

Request for a quote

GEBR. RETTBERG GMBH

Germany

Evaporatorsystem EVA-LS1-MT for 1 Mikrotiterplate, comprising: Motor driven lift with operating unit, Rotable gas dosing unit with 96 permanently open outlets, cannulas made of stainless steel coated with PVDF hose,1 pc Gas inlet stop cock, 2 m PUR-hose ID 6mm, AD 8,7 mm Metalblock-Thermostat LS-1V-130, max. working temperature 130°C , Heating block HB-LS1-MT, 96 dwells The system can be modified to meet your specific needs.

Request for a quote

MÜLLER GMBH

Germany

Container handling & container lifting Robust and reliable stationary container handling systems are required where high weights have to be managed effectively. In pharmaceutical production, in particular, Müller's well-thought out container lifters are an integral part for the greatest variety of process tasks. We develop mobile and stationary designs to meet your requirements. The stationary container handling systems are equipped with robust forks and a weighing unit, if required. Container lifter with grinder lift column Type FTHSK 1000 G5-2 lifting weight 1000 kg height 6 m Design: lifting, inverting, swivelling, grinding - all motorized Container Wash Station high pressure, 150 bar warm-cold water rotating injection nozzle validation possible Container lifter for rectangular containers lift and swivel column Type FTHS 1000 G4 loads up to 1000 kg column height 5.0 m Design: motorized lift manual swivel Emptying and charge weighing Emptying and charge weighing system for..

Request for a quote

MÜLLER GMBH

Germany

All our drum lifters do not only handle your drums safely, they also meet GMP-standards. All lifting, inverting and swiveling columns work with electric motors which is very low noise level and operator friendly. For all different types of drums we can offer drum lifters with suitable pick up systems. The slim but stable mast offers the operator a safe visibility to the load. You can manage all handling operations like feeding of tablet presses, capsule filling machines, blister packaging machines, sieves or other transferring tasks with a Müller drum lifter. The lifting operation is always done by electric motor, all other operations like clamping, inverting and swiveling can be done either manually or by electric motors. Drum lifters from Müller are known for economic, save and ergonomic drum handling. Drum lifters with universal clamp lift / swivel / invert column Type FTHSK 300 G2 loads up to 300 kg column height 3.6 m Design: motorized lift manual grip, invert and swivel...

Request for a quote

MÜLLER GMBH

Germany

Müller drum and container blenders - almost like plug and play. Blender or blending column, drum or container – bulk solids such as granules or powders are mixed reliably by an intelligent system; which if required can provide a data report for tracking blender settings such as weight, mixing times and number of revolutions. You therefore have complete documentation for your quality assurance system. Müller drum and container blenders are adaptable for your processes: Gentle action Highly effective Safe Blending parameters can be set With data report Blending column with weighing facility Container tumbler FTHMW 1500 MG8 Lifting weight 1500 kg Height 6 m Design: tumbling and weighing - fully automatic emptying Container Blender Lift / swivel / tumble column Type FTHMS 600 MG7 Loads up to 600 kg Column height 4.0 m Design: motorized lift, swivel, grip and tumble actions Stationary blender for drums Tumbling stand Type FTMh 300 MG1 Loads up to 350 kg Height of unit 1.6...

Request for a quoteResults for

Lift motor - Import exportNumber of results

27 ProductsCountries

Company type