- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical engineering supplier

Results for

Mechanical engineering supplier - Import export

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

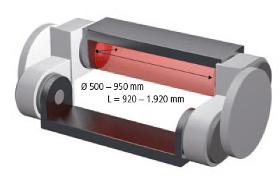

As one of the largest independent contract manufacturers in Germany, the Pritzwalk gear factory (ZWP) based in Brandenburg undertakes the following production: Ring gears, gears, planetary gears, sun gears and shafts with internal gearing. Due to our generous outdoor storage area, ZWP can store the raw material for long-term procurement projects. This means that there are no lead times for special materials, so that a waiting time of e.g. 3-6 months can be avoided. Immediate access to materials is possible and production can take place immediately. The rising raw material prices, long waiting times or availability of the material used make warehousing and production according to defined lot sizes interesting again. Delivery call-offs can be made with immediate delivery capability and cost savings. Finished parts are of course preserved inside. We are looking for a conversation with you for a holistic solution.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

MFZ SERIES – FIT 2 PART – YOUR TASK DEFINES OUR MACHINE. Highest performance and output per square meter, at the same time lower costs and higher productivity – that was the task for our engineers and developers at SAMAG MachineTools. The result: the MFZ series with FIT 2 PART. The conception of the new series leaves nothing to be desired. Technological know-how - for the highest precision with the greatest possible productivity - coupled with passion and innovation, means we create the opportunity to continue adapting the performance of our MFZ machine tools to your workpiece in the future - FIT 2 PART! Whether they have complicated workpiece dimensions or are looking for the optimal quantity solution with minimal machine investmen

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

QUICK CHECK GUN DRILL Eight basic cycles, based on experience, are included in the scope of delivery of the machine and guarantee professional processing of the workpiece. Specific groups for cross drilling cycles are available as an option. This makes workshop programming and programming of crossing holes easier by adapting the feed when hitting the cross hole. This increases the tool life significantly.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

4-spindle solution for pre-processing 2-spindle solution for fine boring with independent X, Y and Z axes Cycle times less than 30s possible

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

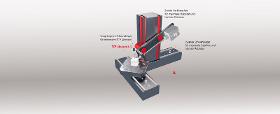

STABILITY AND HIGHEST PRECISION COME BY APPROXIMATE. THE PERFECTLY THOUGHTFUL AXIS CONCEPT IN THE POWER TOWER DESIGN ALLOWS MINIMAL TCP DISTANCE AND MAXIMUM MACHINE STIFFNESS. The POWER TOWER DESIGN impresses with its compact design and extreme rigidity. All components in the force flow are statically and dynamically optimized down to the last detail, thus ensuring perfect work results. The clear separation of all linear axes guarantees long-term dimensional accuracy of all axis drives and sustainably prevents tolerances from overlapping and thereby increasing. Thanks to the large footprint of the Y-tower and the unique DOUBLE BALL SCREW DRIVE, we always achieve optimal support for the drill beam in the TFZ and at the same time an extremely short distance between the swivel bearing and the tool center point (TCP distance), for maximum rigidity with large transverse forces.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center, year of construction: 2008 Product name: MFZ 2-2 Update Used 2-spindle horizontal 5-axis machining center Year of construction: 2008 Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (machine without coolant system and accessories) X-axis travel: 450 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 450 mm Rapid traverse XY Z axis 60,000mm/min 2 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm Spindle distance 450mm Chip conveyor Knoll (scratch belt conveyor in positioning variant across the machine) High-quality Knoll KSS system with fine filtration Flush gun Complete enclosure Tool storage (2 x 50 tools) Operating voltage 400V 3N ~ Control voltage 24V DC Connection value machine approx. 72 KVA Compressed air connection 6 bar

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

4 SIZES AND LOTS OF POSSIBILITIES! THE SFZ SERIES ESPECIALLY SCORES WITH STRONG PERFORMANCE. Starting from the four basic models of the SFZ series; We offer modular equipment variants, depending on performance requirements. Completely in the spirit of FIT 2 TASK. In order to guarantee individual performance, the SFZ machines are equipped with the latest generation of Heidenhain iTNC640 controls as standard. SIEMENS 840D SL is optionally available as an alternative, depending on your requirements.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

PENDULUM CHANGER – GOOD FROM EXPERIENCE. The W-axis principle, established by SAMAG since 1995, enables workpiece loading to be carried out parallel to production times. The workpiece carrier table is moved in the swivel drive from 0 – 180°. This means that the next loading and unloading of workpieces can take place during processing. Efficient and useful also for robot-assisted loading.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

The frame construction concept offers reliable stability thanks to its closed design. The power transmission through the axis movements in the working area does not cause any deformation of the frame. This extremely stable solution is a prerequisite for the high-precision machining of your workpieces and guarantees consistently high process quality. The new generation of the MFZ is also built on the solid machine bed with Hydropol ® filling. The specially developed composite material improves the stability of machine tool beds. Hydropol ® makes a further step possible in terms of the interaction between energy efficiency and high productivity.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

SIMPLY ROTATE THE 3D UNIT BY 90° AND THE MASS THAT HAS TO BE MOVED IS ONLY HALF AS BIG! ZERO GRAVITY DRIVE – OR TURN WITH MASS. Through the rotation and the resulting reduction of the mass to be moved - by around half - we can use the ZERO GRAVITY DRIVE to achieve an incomparably efficient, dynamic and stable type of spindle movement in all three spatial axes. This new kinematic concept is unique in multi-spindle machining centers and enables maximum efficiency and absolute precision on the one hand and maximum utilization and extreme cost-effectiveness on the other.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

2-spindle solution with a 4-part clamping device Editing the OP 20 after the turning process Piece time less than 90s possible

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

4-spindle solution with HSK-A100 on MFZ Machining of the free cut with 4 spindles possible OP 10 and OP 20 are processed in one machine Unit times less than 50s possible

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles OP 10 and OP 20 are processed in one machine Complete processing in 67s

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 4 spindles OP 10 with 4 part clamping on workpiece carrier unit OP 20 with 4 workpieces on 2 rotary tables (5-axis machining

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

2-spindle solution with 4 parts clamping Processing in one setup Machining time less than 82s per workpiece Machining with 4 spindles Tool monitoring for all tools takes place parallel to production time

Request for a quoteResults for

Mechanical engineering supplier - Import exportNumber of results

16 ProductsCompany type