- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining of metals

Results for

Machining of metals - Import export

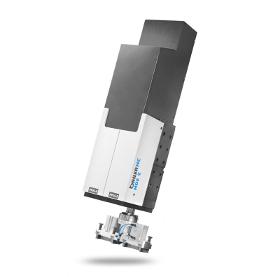

MESUTRONIC GMBH

Germany

metal separator was developed for the examination of plastic granulates, ground material and powders for metallic foreign bodies. It is used in the injection molding and extrusion areas for slow-flowing material columns. Both the detector and the ejection unit have been specially developed for this area of use. This results in top performance data for precision, operating reliability and ease of cleaning. Failsafe storage of all system parameters Digital signal processing for best detection Process- and condition monitoring Standardised system for a wide area of use Robust construction for maximum lifetime Highest precision in long-term operation Fast ejector for minimized material loss Dismantle without tools All components are easily accessible

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Maintenance oil for dismantling, lubrication and care of machine elements and metal surfaces. Dismantling of all seized or sticky components or machine elements, e.g. door locks, hinges, screws, bolts, bushings, cranks, linkages, valves, slide rails, cable pulls, shafts, etc. Lubrication of fine-mechanical instruments, measuring instruments, office and computer equipment etc., even at low temperatures Advantages and benefits Highly effective due to ideal combination of mineral oil and additives with solvent Broad range of uses in the complete maintenance sector Displaces moisture, protects against corrosion Cleans, maintains and lubricates Gets under rust

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

The latest addition to the RUF Maschinenbau portfolio, the low-cost RUF Formica, is a new briquetting system designed for the metals industries. Configured for small to mid sized batches in a wide range of applications, it frees a lot of storage space and simplifies logistics, making it in addition an attractive investment for production companies generating only small chip quantities.

Request for a quote

FATH GMBH

Germany

To mount leveling feet, rollers, hooks or similar components; connects to the profile sideways Various shapes and designs on request Material: Die-cast aluminum, Aluminium die-cast Surface: Plain, black powder coated Specials: Other surfaces, other colors on request

Request for a quote

SYSKOMP GMBH - EMICO

Germany

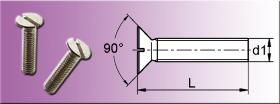

Countersunk screws - metal ~DIN 963 (~DIN EN ISO 2009) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

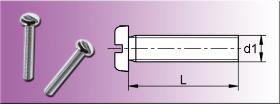

Pan head screws - metal ~DIN 85 (~DIN EN ISO 1580) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

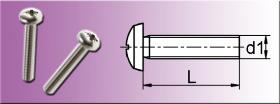

Lens head screws - metal, cross slot ~DIN 7985 (~DIN EN ISO 7045 - form H) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

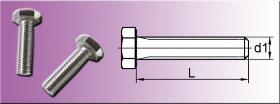

Hexagon head screws - metal ~DIN 933 (~DIN EN ISO 4017, threaded to head) Material: machining steel 4.8 zinc-plated

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Pulse rate: max. 200 1/min Processing radius: max. 100 mm Vertical stroke: max. 120 mm

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Forming force NCA 2: max. 1500 N / 5000 N Stroke: max. 60 mm / 120 mm / 240 mm Forming force NCA 3: max. 3500 N / 8900 N Stroke: max. 120 mm / 200 mm Forming force NCA 4: max. 12000 N / 19000 N Stroke: max. 120 mm Forming force NCA 5: max. 31000 N / 47000 N Stroke: max. 100 mm Forming force NCA 7: max. 190000 N / 200000 N Stroke: max. 140 mm

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: max. 200 1/min Nominal force: 800 kN Stroke range: fixed stroke with 30 mm Stroke position adjustment: - 8 mm from B.D.C. Tool mounting plate (LxW): 1000 mm x 510 mm Opening size in B.D.C.: 324.5 mm Column opening: max. strip width 160 mm

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Complete system incl. positioning Screw type: Phillips, torx, slotted Output: max. 140 1/min. Feed speed: 424 mm/s Stroke: 50 mm Screw size:: max. M8

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: max. 1,200 strokes/min (20 mm feed pitch) Feeding speed: max. 3.2 m/s Feeding force: 1,000 N Feeding accuracy: ± 0.02 mm Hydraulic clamping pressure: 3,000 N – 7,000 N Transport temperature: max. 60°C Strip thickness: max. 9.0 mm Strip width: max. 300 mm Strip diameter: max. 9.0 mm

Request for a quote

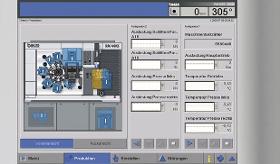

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

VariControl VC 1 - One control platform for all tasks With the VariControl VC 1 machine and process control system, Bihler emphasizes the keywords „Ease of Use“ and „Process Safety“ at a new, higher level. With state of the art software and hardware features, the intelligent control system guarantees greater efficiency in your production. The highly flexible control platform allows you to easily control even the most complex automation solutions in the field of stamping and forming assembly technology – on all Bihler machine types. The integrated „bASSIST“ diagnostic and online help system assists your machine operator just like a second operator at his or her side. Videos, graphics and individually created data simplify adjustment, setup and maintenance operations significantly. The continuous monitoring of all machine and tool functions guarantees maximum machine availability.

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable from 5 to max. 700 1/min. Press: nominal stamping capacity 300 kN, stroke 10 mm Slide units: max. nominal forming capacity 50 kN, max. stroke 10 mm Feed length: mech. feed: max. 120 mm or 240 mm, with feed cycle reduction, servo feed: any feed pitch Material: max. strip thickness: 4 mm, max. strip width 80 mm, max. wire Ø 4 mm Dimensions: width 2,950 mm x depth 1,400 mm x height 2,190 mm Weight approx. 7,500 kg

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable up to max. 300 1/min. Press: nominal stamping capacity 200 kN, stroke 12 mm Servo units: max. nominal forming capacity 31 kN, max. stroke 100 mm Feed length: servo feed: any feed pitch Material: max. strip thickness: 4 mm, max. strip width 40 mm, max. wire Ø 4 mm Dimensions: width 2,600 mm x depth 1,900 mm x height 2,650 mm Weight: approx. 4,500 kg (without tooling)

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Highlights: Very fast “Time to Market” for new stamped and formed parts made of wire and strip as well as progressive components •Quick feasibility statements and precise quotations (“Bihlerplanning” WebApp, defined process limits) •Simple and structured design methodology of bNX software (WebApp for design support, templates) •Very short tool production times (high proportion of standard machine and tool parts) •Up to 70% lower manufacturing costs compared to conventional forming tools •Extremely fast, 100% reproducible setup operations (automatic slide positioning, quick clamping systems, data retrieval from VC 1 control system) •Lower logistics and maintenance costs

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability -Particularly suitable for single-piece production if you wish to make your vice rotatable -Can be removed at any time -Swivel base supporting edge larger than the vice‘s maximum clamping range -Swivels 360° without indexing -Alignment on the machine with T-keys in slots in the swivel base -Clamping slots arranged in the form of a ring for machines with different slot spacings

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -Ideal for use on 5-axis machining centres due to its compact design -With support jaws, unmachined parts with varying types of flame-cut and sawn materials and even complex castings can be clamped safely and economically. Gripper studs suitable for materials of mechanical strength of up to approx. 1000 N/mm². Product features: -The centre is adjustable. The position of the workpiece stays within set boundaries. -Repeating accuracy ± 1/100 mm for angled workpieces -Clamping range presetting via adjustment of clamping jaws along transverse slots of spindle nuts -Moulding and clamping in a single step, directly in the work area – no auxiliary aids required -Fully enclosed and maintenance-free high-pressure spindle – high chip protection, minimum cleaning requirements, constant clamping forces up to 40 kN

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -For horizontal & vertical usage-suitable for CNC controlled milling machines & large machining centres -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely -Gripper studs suitable for materials with a strength of up toapprox. 1000N/mm² Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models -Fully compatible with the accessories of the LC/TC 160 series, for example gripper studs, universal gripper set & pull down sets -Grounded sides so that all sides can be used High-pressure spindle with mech. force amplifier for the safe clamping of raw parts in combination with gripping & pull down spring function -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -The classical, universal clamp, for vertical 3 axis machining centres -Conventional clamping and gripp clamping possible -Clamping of raw parts, burn and saw cuts by penetrating hardened and interchangeable gripp elements into the workpiece Customer advantages: -Free of charge introduction to gripp technology in comparison to conventional clamping (LC) -First and second clamping stations without retrofitting the step jaws Clamping of raw parts such as burn & saw cuts (materials up to approx. 1000N/mm2) through screwable clamping applications (first clamping station) -Parallel clamping to machined workpieces with the step jaws (2. clamping station) Product features: -The high-pressure spindle allows you to, with a mechanical force amplifier (using the torque wrench), to work and clamp to a table -Stable GGG60 body, grounded top and bottom -Precise tracks in the grounded surface of the soles for optimum alignment on the machining table

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation -Suitable for conventional clamping and for gripper clamping or a combination of both -The support jaws enable a wide range of unmachined parts from flame-cut and sawn materials through to complex castings to be clamped securely and economically. Suitable for materials Product features: -Clamping range adjustment for clamping two workpieces of different sizes -Reproducible clamping forces enable excellent repeating accuracy of the workpiece position -Mechanical power-transfer device -Fully enclosed and maintenance-free high-pressure spindle – high chip protection, minimum cleaning requirements, constant clamping forces up to 40 kN -Use with a torque wrench – max. 40 Nm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm Important: -LC 200: jaw width 200 mm, width of vice base 164 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force - Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Conventional and CNC-controlled milling machines – for efficient precision machining -Horizontal installation – great variability and flexibility Product features : -Excellent ease of operation guarantees optimal handling in every situation -Fast adjustment for clamping range preselection -The clamping force is generated and preset via the hydraulic pressure of a hydraulic unit -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped -Coarse adjustment is performed by turning the spindle. The residual stroke of up to 4.5 mm is performed via a hydraulic unit with spring reset by means of a single-acting cylinder

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Conventional and CNC-controlled milling machines – for efficient precision machining -Horizontal installation – great variability and flexibility Product features : -Excellent ease of operation guarantees optimal handling in every situation -Fast adjustment for clamping range preselection -The clamping force is generated and preset via the hydraulic pressure of a hydraulic unit -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped -Coarse adjustment is performed by turning the spindle. The residual stroke of up to 4.5 mm is performed via a hydraulic unit with spring reset by means of a single-acting cylinder

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Product features: -Excellent ease of operation guarantees optimal handling for every application -Fast adjustment for clamping range presetting -Reproducible clamping forces are achieved using a torque wrench Integrated scrapers ensure functional reliability and minimise cleaning Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base Optional centre jaw allows two or more workpieces to be clamped Scope of application: -Conventional and CNC-controlled milling machines – for efficient, precision machining -Horizontal installation – great variability and flexibility

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quoteResults for

Machining of metals - Import exportNumber of results

76 ProductsCompany type

Category