- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- screws - machines

Results for

Screws - machines - Import export

OTTO EICHHOFF GMBH & CO. KG

Germany

During re-machining, a cutting tool is used to remove material from a workpiece in order to shape or surface it as required. We offer re-machining (turning, twisting) as wage work. The following machining operations we offer: Turn thin stem, pins and tips Screw punctures, approaches and undercuts Heads of screws / cold shaped parts machining process (turning) further machining operations are possible on request. Our curve-controlled automatic Audrema lathes offer you further possibilities of finishing cold-moulded parts. These automatic lathes are designed to achieve maximum precision and reproducibility at high throughputs. Short loading and unloading times permit economical production of medium-sized and large series.

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Differential assembly with torque and angle monitoring Positioning the 5 screwing units to screw in 2 x 5 screws in succession

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Audio assembly parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Precision machine screw fittings.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

these screws are used in different machine.

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Self Driving Drilling and Pile-Driving Machines

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Post Puller

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Angle Drilling Machine Valve Opener

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Impact Wrenches

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Sinker Drills

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Hammer Drills

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Post Drivers

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Ground Drivers

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Mounted Earth Augers

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Earth Augers

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Core Drills

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Drilling Machines

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OTTO EICHHOFF GMBH & CO. KG

Germany

Metric: Screws from M2 x 10 – M30 x 1000 with thread (up to 100 mm long). Compliant with DIN, EN, ISO, or according to drawings and samples. Plates: From ST 2.9 x 19 – ST 6.3 x 160 / 80 mm with thread (up to 80 mm long). Compliant with DIN, EN, ISO, or according to drawings and samples. KTG screws for plastics: 30-degree thread (OEB Kunst). KTG 3 x 10 mm – KTG 8 x 160 mm with thread (up to 60 mm long). DIN 7500 thread grooving screws: For die casting, zinc or aluminium. M3 x 20 – M10 x 160 mm with thread (up to 50-60 mm long) (OEB Furch). DIN 7513 – DIN 7516 thread cutting screws: For die casting, zinc or aluminium. M3 x 20 – M10 x 160 mm with thread (up to 50-60 mm long) (OEB Schneid). Other thread types: With-Worth, HiLo, UNC/UNF, double-start, triple-start.

Request for a quote

SPIROL

Germany

Series RH600 Twist-Lok™ Pins replace costly screw machined pins and eliminate problematic installation of screws and rivets. The helical knurl minimises stress during installation by rotating as it engages the hinge. Corrosion-resistant material and a rounded burr-free head improve installed appearance. Axial and radial forces induced in the hinge eliminate the tendency for the pin to creep and maintain hinge tension.

Request for a quote

FATH GMBH

Germany

To connect two aluminum profiles at right angles 1 Profile connector 90° (Set) Model: Steel, slot 8 - 10 Surface: Zinc plated Set 1-I: 1 profile connector 90° with 1 self-forming screw S7 x 22 or S8 x 25 Set 2-I: 1 profile connector 90° with 1 screw M8 x 22 or M8 x 25 Set 1-B: 1 profile connector 90° with 1 cutting bush S12 and 1 screw M8 x 25 Set 2-B: 1 profile connector 90° with 1 threaded bush M12 and 1 screw M8 x 25

Request for a quote

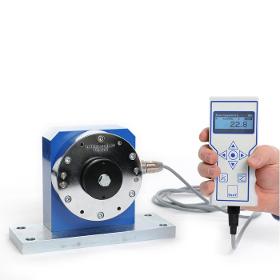

TEST GMBH

Germany

Friction coefficient testing machines of model series 205 by TesT are market-leading, with patented components and always built according to most modern test methodologies. Thus, TesT has created an instrument for safe and fast testing of screw connections for screws and bolts of M3 to M80. The determination of friction coefficients is in the focus of analysis.

Request for a quote

TEST GMBH

Germany

For simple applications TesT offers a manual alternative as a reasonably-priced and fast possibility of friction coefficient determination (model series 206). The associated software package allows simple evaluations and graphical illustrations. Here too, the friction coefficient determination is in the focus.

Request for a quote

TEST GMBH

Germany

As an extension to the friction testing machines TesT offers vibration testing machines for testing according to "Junker". Primarily, these machines are used for dynamic tests of safeguarding characteristics of fastening elements under transversal load (e.g. DIN 65151). A further development allows testing of larger screws, currently up to M42.

Request for a quote

MINEON HANDEL GMBH

Germany

Zinc Alloy and Stainless Steel versions available,Opening angle 180°,Easy Installation,ROHS compliance.Widely used in all kinds enclosures,machines,generators.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification using a portioning device - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport Design: - Simple assembly (plug and play) - low installation costs - Explosion protection model is optional - Good visibility and accessibility - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system - Standard version with 1 working station - Few moving parts resulting in minimized sealing and maintenance costs Drive: - Precise compliance with the torque specification using the slipping clutch or permanent magnet coupling - Screw spindle with adjustable speed Manufacture/Closing: - Simple integration into existing packaging technologies - Processing all standard types of caps

Results for

Screws - machines - Import exportNumber of results

26 ProductsCountries