- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine design designing

Results for

Machine design designing - Import export

MAGNESCALE EUROPE GMBH

Germany

High resolution magnetic absolute linear encoder system for CNC machine tools with robust design. The read head is guided contactless without ball bearing Measuring lengths: 70mm - 3.770mm Accuracy: 3+3ML/1.000 µm(p-p) Max. Resolution: 5nm Max. Response speed: 200m/min Extremely robust against vibration and shock Insensitive to contamination such as oil, water, moisture and dust due to the magnetic operating principle Same thermal expansion behavior as steel or cast iron machine bed Compatible with serial protocols from Fanuc, Mitsubishi and Siemens Siemens DriveCliQ version is Functional Safety certified

Request for a quote

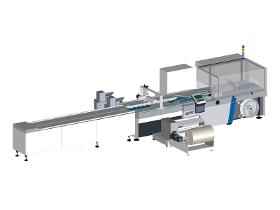

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Paper or film? Stay flexible! A single machine can now deliver both film and paper packaging applications. The continuous Form Fill and Seal Machines paper X hybrid are designed for packaging goods in paper or film. A simple changeover ensures you are ready for the new product and the new packaging material. Whether using a chain infeed or infeed conveyor, the machines stand apart through their continuous packaging process – without stop-and-go – maximising efficiencies by ensuring there is no downtime when sealing or glueing. Our paper packaging solutions are available in different versions, depending on how flexible you need to be: - the basic model paper X features paper packaging with overlap on top - the paper X hybrid features paper and film packaging with overlap on top - the paper X hybrid advance features paper and film packaging with overlap on top and side seal

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The focus is on intermittent sealing of top seals, e.g. of stand-up pouches, despite any product residues present. The vibration of the ultrasonic tool allows for obtaining reliable joint quality despite dusty or pasty filling contents. Burns caused to the packaging material during machine downtimes are safely prevented. The Herrmann SUP module is optimally suited for integration in new machinery or as retrofit in existing machine designs. Designing the module as IP67 variant, the top seal module is also suitable for wash down.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The workshop unit 322 is a name plate marking unit and is used for very deep markings to mark individual components, prototypes and limited-lot productions. Stable, long life and low-maintenance machine design. Designed for continuous production. Available marking technologies: scribe, stylus, dot marking or DataMatrix marking.

Request for a quote

ASSFALG GMBH

Germany

The SMA 40-A series is available in an electrical or compressed-air operated design. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 16 mm is possible in NE metals and a chamfer width of up to 12mm in steel. In addition to this, a radius processing of 1.2mm to 8mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The electrical design of the SMA 40 is equipped with a speed control and should be preferably used for stainless steel processing. The cutter heads are available for chamfer angles between 0 - 80°. The processing of drill holes is already possible starting at a diameter of >28mm. For tight contours, long holes and bores, a single-cutting cutter head with a fitting guide roller is available, Ø10mm to Ø20mm depending on application.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ASSFALG GMBH

Germany

The SMA 20-A series is available in an electrical or compressed-air operated design. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 7 mm is possible in NE metals and a chamfer width of up to 4mm in steel. In addition to this, a radius processing of 1.2mm and 2.5mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The processing of drill holes is already possible starting at a diameter of >20mm.

Request for a quote

ASSFALG GMBH

Germany

The SMA 60 is available in an electrical, compressed-air or high-frequency design. The machine is designed for handling steel, aluminum, copper and plastics. In NE metals and steel up with a tensile strength of 600N/mm², a chamfer width of up to 30mm is possible. In addition to this, a radius processing of 1.2mm to 15mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The cutter heads are available for chamfer angles between 0 - 80°. The processing of drill holes is already possible starting at a diameter of >28mm. Advantages: Booster technology for a higher material removal rate Spring technology for higher service life of cutting inserts Processing chamfers, radii on sheets, containers, inner and outer edges, contours and drill holes Replaceable cutter head for different chamfer angles 0 - 80° Easy and vibration-free work

Request for a quote

ASSFALG GMBH

Germany

The SMA 50-A series is available in an electrical or compressed-air operated design. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 20 mm is possible in NE metals and a chamfer width of up to 15mm in steel. In addition to this, a radius processing of 1.2mm to 8mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The cutter heads are available for chamfer angles between 0 - 80°. The processing of drill holes is already possible starting at a diameter of >28mm.

Request for a quoteResults for

Machine design designing - Import exportNumber of results

9 ProductsCompany type