- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metallurgy - machinery and installations

Results for

Metallurgy - machinery and installations - Import export

IMM MASCHINENBAU GMBH

Germany

Heavy duty polishing and belt grinding jack. For belt linishing, grinding and polishing of surgical instruments, faucets, castings and other work pieces.

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

"haacony". Universal spindle support for craft and industry. Self-locking spindle support, load on head upto 800 kg, load on adjustable claw upto 300kg, load suspension from 16 mm clearance above surface, removable crank, options

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Hand driven all purpose gear drive for multiple applications. Motor drive possible for a speed up to 60 revolutions/min. robust and reliable maintenance-free security crank with internal self actuating load brake alternatively without self actuating load brake for shifting of loads can be equipped with: one or several rope drums chain wheels for roller chains chain sprockets for link chains with crank extensions with crankshaft extension

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Rack jack produced to DIN 7355 norm and company standard, with lifting housing and solid claw, allowing an easy lift of any load, SIKU safety cranks or RAKU ratchet cranks, loading on head or on claw

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Spindle support S/DZ600 Spindle support for comfortable levelling of drawbar, with stop-choc elements, push-pulling dyn. load 2 t, static load 5 t Supporting legs Drawbar and trailer support gear, rugged and reliable, for heavy loads

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Spindle supports, self-locking, manually operated, for ergonomic adjusting and supporting, for levelling and dislocating, etc., optionally with removable crank and parallel working, load 0,5 up to 3 t

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Manual cable winches for wall & console mounting. Made of steel, galvanised or powder-coated, aluminium or stainless steel, from 50 kg to 3000 kg. Hand rope winch 'TANGO' for wall mounting. Load 300 kg and 500 kg. Direction-independent rope outlet, encapsulated housing, foldable crank handle, optionally galvanised or stainless steel. Hand rope winch 'TANGO' for console mounting load 300 kg and 500 kg. Direction-independent cable outlet, encapsulated housing, foldable crank handle, optionally galvanised or stainless steel Manual winch 220.03 - Load 300 kg Manual winch 220.05 - Load 500 kg Manual rope winch 4216 - load 250 kg and 500 kg Hand winch 4202 inox stainless steel - load 500 kg Manual rope winch 4483 - max. load 650 kg Manual rope winch 4185 - Load 500 kg Manual winch 4751 - Load 400 kg

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

haacon hebetechnik gmbh expands its standard range to include rack and pinion winches with fastening lugs for wall mounting. The serial drive type is a spring-loaded safety crank (SiFeKu), which holds the load in any desired position under tensile and compressive loading. The winch can be utilised in any position. The winches are produced in three load classes: 1.5 t 3 t 5 t. The robust design with milled gear rack and hardened gear components is suitable for use in harsh applications. The crank handle can be moved for space efficiency. Special designs with other rack and pinion lengths, detachable crank design, assembled fastening options can be supplied at short notice.

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Roller set for moving of ISO containers Steering rod for easy manoevring of dismantled roll and for steering Including brake Set consisting of towing bar, four steering wheels, locking in driving direction Rolling up to 6 km/h

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Rack jack produced to DIN 7355 norm and company standard, with lifting housing and solid claw, allowing an easy lift of any load, SIKU safety cranks or RAKU ratchet cranks, loading on head or on claw

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Container rollers with load upstroke for lifting and moving of ISO containers Set of rollers consisting of drawbar and four corner units Rolling up to 6 km/h

Request for a quote

ASSFALG GMBH

Germany

Pole extensions are the perfect complement to the square pole magnetic clamping plates and modules. Workpieces with any structure can be perfectly clamped with Assfalg pole extensions. The pole extensions adjust optimally to the shape of the workpiece. The workpiece is underpinned and is located safely on the extensions,, for a five-side complete processing free of vibration and warping. The surface of the magnetic clamping plate is additionally protected against accidental damage through, for example, deep drilling. Another possible application is use as a stop for 3D forms, round material and smaller workpieces. Other pole extension or pole placement plates are available on request. The connection cables are available in different lengths. They connect the magnetic modules with each other in a row. The controller is additionally connected with the magnetic module through this. The cables are protected against hot chips and cooling water.

Request for a quote

ASSFALG GMBH

Germany

The electronic reverse polarity controllers are used to turn the magnetic clamping plates on and off and to regulate the holding force in several stages through the affiliated manual operating device. With the D50 controllers, up to 100 poles with the pole size 50x50mm or 50 poles with the pole size 75x75mm can be switched. Furthermore, the D100 controller is needed. The single-channel devices D50 and D100 are used to control Magnaslot and Doublemag. The D50-2 controller is needed to operate the Triplemag magnet modules with additional holding surface. If multiple magnetic clamping plates are controlled individually, the D100-4 controller must be used. Up to 4 clamping plates can be switched separately here. Individual requests can be implemented upon customer request.

Request for a quote

ASSFALG GMBH

Germany

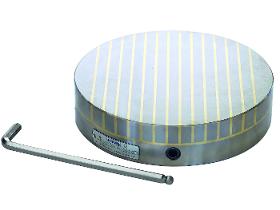

The uniform radial pole division offers significant advantages compared to magnetic chucks with parallel pole or square pole division in particular when processing rings and discs that are difficult to hold as well as sleeves. A higher stability and stiffness can be achieved through radial pole division in particular with larger diameters. A centric through-hole can be incorporated in the area that has no active magnet. The electropermanent magnetic chuck EPMradial from Assfalg is ideal for clamping big, rotationally-symmetrical workpieces (for example, bearing ring processing) starting at a diameter of 400 mm, in particular on rotating and milling machines as well as drilling machines without distortion. The EPMradial electropermanent magnetic chuck permits an extreme takeoff during the hard processing of rings. The highest precision is achieved during grinding work.

Request for a quote

ASSFALG GMBH

Germany

Whether while milling (rough and finish machining), drilling, sawing, welding or assembling, the EPM modules or module systems offer a large selection of clamping options, for example, to clamp during edge milling or deburring (without mechanical clamping equipment) or for the simple and quick fastening of workpieces during assembly. Workpieces can be easily and quickly fastened with the Triplemag magnet clamping elements. The Triplemag series has additional positioning magnets, ensuring a constant position on the machine table and which are separately switched. Through the use of pole extensions, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. Using pole extensions, plane-parallelism of up to 0.01 mm is possible on the workpiece. The processing runs without vibration and an even distribution of holding force is guaranteed throughout the entire ferrous clamping surface.

Request for a quote

ASSFALG GMBH

Germany

Whether while milling (rough and finish machining), drilling, sawing, welding or assembling, the EPM modules or module systems offer a large selection of clamping options, for example, to clamp during edge milling or deburring (without mechanical clamping equipment) or for the simple and quick fastening of workpieces during assembly. Workpieces can be easily and quickly fastened with the Doublemag magnet clamping elements. Through the use of pole extensions, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. Using pole extensions, plane-parallelism of up to 0.01 mm is possible on the workpiece. The processing runs without vibration and an even distribution of holding force is guaranteed throughout the entire ferrous clamping surface. Several Doublemags can be combined to process large parts.

Request for a quote

ASSFALG GMBH

Germany

The EPFlux magnetic clamping plate has no remanence (residual magnetism) upon deactivation. Highly alloyed and hardened workpieces can be easily loosened from the magnetic clamping plate. Highest grinding precision is achieved, because the plate is not heated up. Not heated up means that there are no expansion and deformation to the workpieces to be processed. The electropermanent magnetic clamping plate is the ideal clamping plate for precision grinding machines. The laminated surface made of brass and steel and the solid steel body guarantee magnetic holding force as well as unique hardness over the entire surface. With the EPFlux magnetic clamping plate, large and small workpieces can be evenly clamped. The magnetizing and demagnetizing occurs through a short power pulse within seconds.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ASSFALG GMBH

Germany

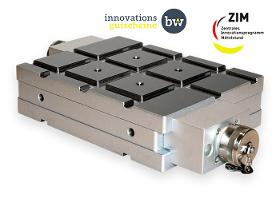

The patented EPM magnetic clamping plates *** Patent-No. EP1874504 *** have a solid steel surface and are therefore significantly more resistant than conventional plates with epoxy resin against hot chips, coolant and other processing influences. The workpiece is clamped on the EPM magnetic clamping plate MAGNASLOT within seconds through an impulse current. This magnetic clamping plate allows for 5-side processing of your workpieces in only one clamp. This reduces equipping times to a minimum and increases productivity. Through the use of pole extensions, which adjust to the workpiece surface, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. The magnet field from the MAGNASLOT magnetic clamping plate guarantees low-vibration clamping of your workpieces. This protects the milling spindle as well as your tools, increases process safety and extends the service life.

Request for a quote

ASSFALG GMBH

Germany

The patented EPM magnetic clamping plates *** Patent-No. EP1874504 *** have a solid steel surface and are therefore significantly more resistant than conventional plates with epoxy resin against hot chips, coolant and other processing influences. The workpiece is clamped on the EPM magnetic clamping plate MAGNASLOT within seconds through an impulse current. This magnetic clamping plate allows for 5-side processing of your workpieces in only one clamp. This reduces equipping times to a minimum and increases productivity. Through the use of pole extensions, which adjust to the workpiece surface, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. The magnet field from the MAGNASLOT magnetic clamping plate guarantees low-vibration clamping of your workpieces. This protects the milling spindle as well as your tools, increases process safety and extends the service life.

Request for a quote

ASSFALG GMBH

Germany

These Neostar magnetic chucks can be used universally, in particular for internal cylindrical grinding, rotating and hard rotating. The uniform radial pole division offers significant advantages compared to magnetic chucks with parallel pole division in particular when processing rings and discs that are difficult to hold as well as sleeves. A higher stability and stiffness can be achieved through radial pole division in particular with larger diameters. A centric through-hole can be incorporated. These clamping plates can be activated through a hexagonal switch lever.

Request for a quote

ASSFALG GMBH

Germany

These highly accurate Magnet Sinetables are used for grinding work as well as for eroding. It allows for universal clamping of small, medium and large workpieces of any thickness, however, they are best suitable for thin and fine workpieces. The permanent Microsine magnetic clamping plate is preferably used if a flat and light construction is needed during grinding, eroding or milling. A complete, fine transverse pole distribution (steel/brass) guarantees a consistent holding force over the entire width up to the longitudinal sides. This clamping plate can be activated through a hexagonal switch lever. They are available in two versions: either single-pivotable via the longitudinal axis or double-pivotable via the longitudinal and transverse axis. Gauge blocks can be used to set the tilt angle precisely up to 45 °. The magnet Sinetable is suitable for accurate grinding of workpieces with nonparallel surfaces. Individual designs can be created on request.

Request for a quote

ASSFALG GMBH

Germany

Each side can be switched separately with this magnetic welding angle. They are suitable for round and flat material. Metal workpieces can be held at 90° with this durable and maintenance-free welding angle. Workpieces can be easily positioned, aligned and fastened.

Request for a quote

ASSFALG GMBH

Germany

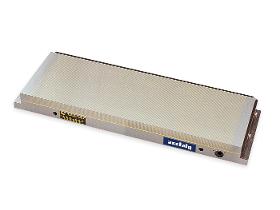

These Permamax permanent magnetic chucks from ASSFALG are suitable for heavy clamp-lifting processing. These Permamax permanent magnetic chucks can be used for milling, rotating and grinding. Considerable holding forces are still achieved on uneven and rough surfaces. They allow for universal clamping of small, medium and large workpieces of any thickness, however, they are best suitable for thick and large workpieces. A complete, wide transverse pole distribution (steel/brass) guarantees consistently high holding force over the entire width up to the longitudinal sides. These clamping plates can be activated through a hexagonal switch lever.

Request for a quote

ASSFALG GMBH

Germany

These permanent magnetic clamping plates Permamax from ASSFALG are suitable for heavy clamp-lifting processing. These Permamax permanent magnetic clamping plates can be used for milling, drilling, grinding and slicing. Considerable holding forces are still achieved on uneven and rough surfaces. They allow for universal clamping of small, medium and large workpieces of any thickness, however, they are best suitable for thick and large workpieces. A complete, wide transverse pole distribution (steel/brass) guarantees consistently high holding force over the entire width up to the longitudinal sides. These clamping plates can be activated through a hexagonal switch lever.

Request for a quote

ASSFALG GMBH

Germany

This highly accurate magnetic clamping plate is used for grinding work as well as for eroding. It allows for universal clamping of small, medium and large workpieces of any thickness, however, they are best suitable for thin and fine workpieces. The permanent Microfine magnetic clamping plate is preferably used if a flat and light construction is needed during grinding, eroding or milling. A complete, fine transverse pole distribution (steel/brass) guarantees a consistent holding force over the entire width up to the longitudinal sides. This clamping plate can be activated through a hexagonal switch lever.

Request for a quote

ASSFALG GMBH

Germany

Our deburring and edge rounding machines type TF enable an optimal Surface Processing up to the perfect surface finish in the dry grinding process. The Deburring & Edge Rounding Machines are available with 3 different passage widths. They have various performance spectrums, which are individually adapted to the modular principle customizable and configurable to customer requirements. Both small and large-area sheet metal parts or workpieces can be processed, regardless of the material. These conveyer machines thus show the best possible flexibility in sheet metal processing.

Request for a quote

ASSFALG GMBH

Germany

Robust and maintenance-free 90° magnetic clamping angle for flat material. The permanent magnet welding angle is a classic from Assfalg for welding and assembly work on flat material. It is available in two sizes, with a base length of 200mm and 300mm.

Request for a quote

ASSFALG GMBH

Germany

The Pivot magnetic welding angle has a holding angle range from 28 to 270 degrees. The Pivot magnetic welding angle is a universal handyman for smaller welding and assembly work on round and flat material. Through the quick release and a scale, the angle can be set simply and precisely. Components can be clamped on the inside or outside. Each leg can be switched on and off through a rotary switch.

Request for a quote

ASSFALG GMBH

Germany

These magnet welding angles can be gradually adjusted in their angle from 30° to 275°. Every leg can be switched separately. These magnet clamping angles hold round and square tubes and flat material secure. Thanks to the engraved scale and the quick release, the angles can be quickly and precisely set.

Request for a quoteResults for

Metallurgy - machinery and installations - Import exportNumber of results

37 ProductsCompany type