- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ultrasonic components

Results for

Ultrasonic components - Import export

HERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

In interaction with the sonotrode, the anvil produces and shapes the joint and thus is one of the core components of the ultrasonic sealing process. Sealing of films requires focusing of the energy by means of the tooling profile, which is mostly mounted to the anvil. Highest rigidity and plane parallelism ensure best joint quality. Anvil profiles are essential for the quality of the weld result and are produced to customer requirements and adapted to respective applications.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Herrmann Ultraschall has long-term experience in the field of fixture design. In order to obtain good weld results, a fixture has to be perfectly adapted to the plastic component about to be welded. Starting with selection of the best suitable material, which ensures damage-free holding of the component, through to special fixing, clamping, or sensor functions, fixtures are customized and specifically designed to meet the respective application requirements.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

For frequency values of 20, 30, and 35 kHz ultrasonic boosters with different gain ratios (transformation) are available. All ultrasonic boosters are made of high-quality titanium. Depending on the required demands, they are installed using rigid or flexible support rings.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Depending on production environment conditions, ultrasonic converters are available with protection ratings of IP50, IP65, and IP67. For rotating operation, a series of ultrasonic converters with integrated HF connection for rotary couplers has been developed. What all ultrasonic converters have in common is their central assembly with solid piezoceramic four-disk technology. The rigid decoupling principle allows for axial and transverse forces. Special manufacturing processes ensure extremely long service life at constant output amplitude.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The optimum oscillation behavior of the ultrasonic sonotrodes is determined by means of FEM (Finite Element Method) calculation. Highest precision requirements in terms of CAD/CAM calculation algorithms guarantee precise 3D contours for sonotrode manufacturing. Measuring and documentation of the amplitude distribution is performed at the vibrating sonotrode using state-of-the-art laser measurement technology. Special surface finishings result in even longer service life spans of the ultrasonic sonotrodes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIMO GROUP GMBH

Germany

Fexible and available at any time FRIMO's ultrasonic standard components can be delivered quickly and used in all common system types or integrated into complex manufacturing lines. During ultrasonic welding/riveting, ultrasonic vibrations (20-30-40 kHz) are generated in the joining surfaces of the thermoplastic components. FRIMO generators, converters, and sonotrodes allow a particularly quick weld (within seconds). The processes can be monitored electronically, and the option of hand welding provides simple emergency strategies.

Request for a quote

JOHNSON MATTHEY PIEZO PRODUCTS GMBH

Germany

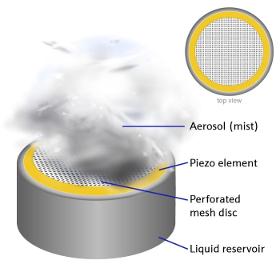

Ultrasonic mesh inhalers, nebulizers and components for example for medical applications

Request for a quoteResults for

Ultrasonic components - Import exportNumber of results

8 ProductsCountries

Company type