- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- waste water centrifuges

Results for

Waste water centrifuges - Import export

FLOTTWEG SE

Germany

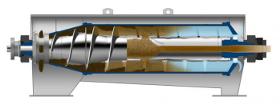

Proven know-how meets state-of-the-art technology. This is the best way to describe the new Flottweg decanter C series. We also have the optimal solution for the very large wastewater treatment plants. The combination of our own Simp Drive® drive system, which has been in use since 1994, and Recuvane®, which allows flexible and simple retrofitting as well as targeted discharge of the centrate water, sets new standards for Flottweg in separation technology.

Request for a quote

FLOTTWEG SE

Germany

The New C2E Decanter Centrifuges for Small Treatment Plants Flottweg presents a new era of sludge dewatering for small sewage treatment plants. The C2E decanter centrifuge was developed specifically for the dewatering and thickening of smaller sludge loading rates. It features all of Flottweg's know-how in a compact, space-saving design. Over five decades, Flottweg has gathered rich knowledge of the area of sewage sludge thickening and dewatering. That know-how has been transferred into a new generation of environmental centrifuges. Our requirements for the C2E are just as high as for the big Flottweg Decanters. Disposal costs still play a central role, even for small communities. The quality of the machine and its efficiency regarding separation results reduces the overall lifetime costs to a minimum. Want to learn more about our solutions? Then get in touch.

Request for a quote

FLOTTWEG SE

Germany

The demands on the quality and efficiency of sewage treatment plants are growing from year to year, not least due to rising energy and disposal costs. As a result, using decanters to dewater sludge means using state-of-the-art technology. The C-series decanters from Flottweg achieve high performance with reduced energy consumption. Flottweg Wastewater Decanters offer advantages over other processes and competitors' machines: ► High dry solids values in the discharged material ► Higher power density within a small footprint ► Powerful Flottweg Simp Drive® drive ► Reduction of operating costs due to reduced need for flocculant ► Additional energy recovery with the Flottweg Recuvane® system ► Economical bowl and scroll drive ► duces the energy consumption of your decanter by 10 to 30 percent

Request for a quote

FLOTTWEG SE

Germany

Flottweg C series decanters around the world process 25 million liters of sewage sludge per hour. The dewatering and thickening of sewage sludge plays a decisive role in the wastewater treatment process. Requirements for the quality and efficiency of sewage treatment plants increase year after year, not least driven by the increasing costs of energy and disposal. As a result, the state of the art is now to use decanter centrifuges to dewater and/or thicken the incoming sludge. Flottweg developed the decanters of the C series especially for this purpose. The C7E represents the largest of all the C machines. The C7E increases the proportion of dry substance in the sludge, thereby reducing its volume and weight (due to loss of water). That means that operators need to dispose of, recycle, or burn less sludge. The result: enormous potential savings for the operators of sewage treatment plants.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

EFFICIENT CLEANING – INTUITIVE, ROBUST AND SEMI-AUTOMATIC IF REQUIREDWith a basket centrifuge from the ZM range, you get a robust and easy-to-operate unit for cleaning up to 1,000 litres of process water per hour. Separate up to 14 litres of sludge in a single cycle! The sludge basket is removed and emptied manually. A PLC is available for semi-automatic operation. CENTRIFUGES IN TWO CONFIGURATIONS The ZM basket centrifuge is available in two configurations to meet your requirements. The ZM 03-ECO 1 is perfectly suited for use on a single mass finishing machine in standard applications and island solutions. For two to three mass finishing machines, the ZM 03-FL is the ideal choice. You can of course retrofit application-specific options like a pump station and recooling unit. THE BENEFITS AT A GLANCE Centrifuges with up to 2,012 times the acceleration of gravity Up to 14 l (19 kg) of sludge per cycle Up to 1,000 l of process water per hour PLC for semi-automatic operation

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTHER TROWAL GMBH&CO.KG

Germany

A clear matter: disposing of process water in an operationally safe manner After vibratory finishing, the process water contains solids and pollutants such as metals, oils and greases. To prevent these from entering the sewage system during disposal, you can clean your process water - even acidic or alkaline water - in our flocculation plants. You can then discharge the clear water into the sewage system in accordance with legal regulations. DO/GA flocculation units The PLC-controlled DO and GA flocculation plants are fully automatic solutions that purify up to 2,000 litres of process water per hour. If your daily water volume to be treated exceeds 3,000 litres, these plants are the right choice for purifying your process water. RT flocculation unit The easy-to-operate and inexpensive RT unit is suitable for you if you want to purify a daily water volume of up to 3,000 litres.

Request for a quoteResults for

Waste water centrifuges - Import exportNumber of results

7 ProductsCountries

Company type