- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high-performance ceramic

Results for

High-performance ceramic - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

BALTEAU NON DESTRUCTIVE TESTING

Belgium

The Ceram Series is a reference in the X-Ray industry for reliability, high performances and robustness. The Ceram 35P is the panoramic brand new portable generators designed by Balteau NDT and is offering no less than 300kV, 5mA and 100% duty cycle for an incredible image contrast even at full power. This unit will surely become a reference on the market as it can be classified as a high power portable unit and can be operated with our classic CF2000 control unit but also with our well known Hand-X Wireless Remote Control. Gas insulation and right components selection have succeeded in producing one of the lightest 300kV panoramic unit.. The unit is extremely versatile and is confirming our reputation of builders for machines that are really made for fi eld.

Request for a quote

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Non-woven cleaning abrasive with ceramic high-performance abrasive grain. For powerful cleaning performance and an extremely long lifetime. • Stable edges • Top cleaning performance • With ceramic high-performance abrasive grains

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Non-woven cleaning tool for the quick change system with ceramic high-performance abrasive grain. • Stable edges • Maximum cleaning performance • Quick tool change without bonding or sliding

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Fillet weld flap disc – the combination of a 10 mm flap projection and rigid fabric makes for a long lifetime. • High stock removal performance through ceramic grain • Optimised for fillet weld work • Optimal price-performance ratio

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Ceramic grain fibre disc – the grain enables superior stock removal performance in a short period of time with a very long lifetime. • Especially suitable for hardened and tempered steels, tinder areas and titanium • Perceivably faster stock removal • Long lifetime

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Continuous-feed belt with ceramic grain for stationary belt grinders. • Bond from synthetic resin with abrasive grain fillers for cooler grinding • Closed coating for high stock removal performance on steel and stainless steel • Tear-resistant X-polyester fabric, waterproof for a long lifetime

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Flexible continuous-feed belt with ceramic grain for hand-guided belt grinders. • Bond made from synthetic resin enriched with abrasive grains for a cooler cut • Closed coating for high stock removal performance on steel and stainless steel • Flexible, tear-resistant cotton T-fabric for a long lifetime

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Quick and aggressive grinding with very high stock removal performance, thanks to a large contact surface and extra-long flaps. • Ceramic grain offers high stock removal performance • Especially suitable for hardened and tempered steel, tinder areas and titanium • Particularly good for edge grinding

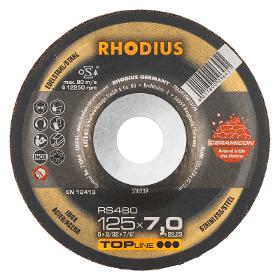

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. High-performance stainless steel rough grinding disc with ceramic abrasive grain. Also performs very well on steel and cast iron. • High stock removal performance • Additional fabric flange from 180 mm for high-frequency and air grinders • Safe thanks to three full-face fabric layers

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Ceramic grain fibre disc for the quick change system – the grain enables rapid and superior stock removal performance. • Especially suitable for hardened and tempered steels, tinder areas and titanium • Perceivably faster stock removal • Quick tool change without bonding or sliding

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

High-performance ceramic - Import exportNumber of results

17 ProductsCountries

Company type