- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hollow pin chains

Results for

Hollow pin chains - Import export

TOSYALI MAKINA A.S.

Turkey

A special link pin design distinguishes hollow pin roller chains from standard roller chains. Hollow pin roller chain links have a similar construction to ISO standard roller chains; They consist of pin, bushing and small pulley, so most chains of this type are compatible with the same sprockets as the corresponding standard chains. Since double chain operation is customary in most applications, we can supply these chains paired. The product range includes various versions of this chain type, such as hollow pin roller chains, hollow pin bushed chains or hollow pin roller chains without bushings, as well as various corrosion-resistant surface finishes (galvanized, nickel-plated, stainless). steel)

Request for a quote

ZIMAS ZINCIR VE MAKINA SAN. TIC. A.S

Turkey

This type of chains are self perforated compared to other chains. These chains, designed specifically for their intended use, can be assembled by making a pin connection from the holes of the two opposing chains in order to fulfill the functionality within the system. They are usually chains that work in the transport product or cabinet lifts. These chains are shipped as mutually matched, stretched and marked.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

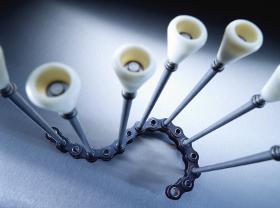

Many ELITE hollow pin chains are constructed to the dimensionsof standard ISO 606. Since customer requirements are so diverse, the ELITE product range has also been adapted to include various versions of this chain type: • Hollow pin roller chains • Hollow pin bush chains • Bushless hollow pin roller chains ELITE highlights: • Available based on the same chains manufactured to ISO 606 or as special chains • All ELITE chain plates 1 are manufactured using processes such as fine blanking and ball-drifting, so a particularly high contact ratio is guaranteed. • Solid, case hardened rollers 2 with good wear resistance • In general, hollow pins 3 made of seamless precision steel tube for improved precision and wear resistance • Many of these chains are supplied pair-matched to ensure exact parallel running, one of the main requirements that these chains must fulfil.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Gearbox lubrication of heavily loaded, relatively slow-running toothed gearing when grease is used instead of oil due to leaks For heavily loaded and impact-loaded drives Chain lubrication, e.g. of hollow-pin chains in the conveyance and transport sector, for exposure to water and steam and at higher operating temperatures Bearing lubrication of friction and rolling bearings in annealing yards and drying systems, manipulators and robots, cooling-bed and conveyor systems, machines in food packing industry, steam sterilisers etc. Advantages and benefits Excellently suited for corrosive operating conditions with high operating temperatures and high pressure and impact loads Economical due to optimised formula Enables wear reduction, decreasing failure times and enabling long-term lubrication Long-acting, highly adhesive, temperature-stable and waterproof, noise-damping, impact and pressure resistant

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of highly stressed and relatively slowly running gears where due to leakage a grease must be used instead of oil For drives under high and shock load Chain lubrication of e.g. hollow pins, chains in the conveyor and transport field, under the influence of water and vapour and at higher operation temperatures Bearing lubrication of roller and plain bearings at annealing furnaces and drying equipments, manipulators and robots, conveyor and cooling systems, machines of preserve industry, steam sterilizers, etc. Advantages and benefits Best use in corrosive operation conditions with high operation temperatures and high pressure and shock load Economically due to optimum formulation Reduces wear and thereby downtime and enables long-term lubrication Ropy, strongly adhesive, temperature and water resistant, noise dampening, high-load and shock absorbing

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Highlights • iwis high precision roller chains: long-lasting, reliable, excellent wear resistance • Special lubrication for can manufacturing: non-drip, high temperature range, approved for use in the food industry • Protection heads: high-temperature and high-performance material. Standard type available, other geometries and materials on request. • Length of transport pins can be adapted to customer specifications • Predefined fracturing points in the pins prevent damage within the lines in case of collision (POChain-P/-S) • Transport pins: easily changed on-site without damaging the chain or removing it from the machine (POChain-P/-S)

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

the context of the ELITE conveyor chain range, iwis suppliesa wide variety of chains according to standards DIN 8165 and DIN 8167, as well as models manufactured according to British Standard with dimensions in inches, and highly diverse special versions. Bush conveyor chains are often used for conveying tasks involving long transport distances at relatively low speeds. Since only a small minority of chains used in the industry are totally compliant with one specific standard, ELITE conveyor chains are custom-made to a specific customer order and consequently fulfil a large number of special requirements. Product range: • Bush conveyor chains according to DIN 8167 – M Series • Carrier chains with rollers according to DIN 8167 – MT Series • Hollow pin chains according to DIN 8168 – MC Series • Hollow pin chains according to DIN 8165 – FVC Series • Scraper chains according to DIN 8165/DIN 8167 • Conveyor chains for the paper industry • Rotary chains

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

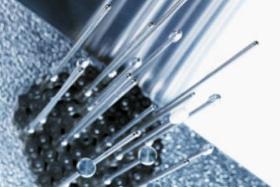

Highlights: • Wide range of products • Dimensions according to ISO 1275 • Versions with small rollers and transport rollers available • All ELITE chain plates 1 are manufactured using processes such as fine blanking and ball-drifting, so a particularly high Product range: • Double pitch roller chains ISO 1275 • Double pitch roller chains with straight plates ISO 1275 • Double pitch hollow pin bushed chains • Double pitch hollow pin roller chains contact ratio is guaranteed. • Solid, case hardened rollers 2 with good wear resistance • ELITE pins 3 are smooth and have an extra hard surface for increased wear resistance

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

iwis high performance chains – roller chains with rust-resistant, easy to change attachments. Exclusively from iwis. Highlights • Transport bars can be changed easily on site using the special iwis tool provided; no need to break the chain or remove it from the machine • Adapter and bars made of highly alloyed, corrosion-resistant steels with good elastic characteristics • iwis standard roller chains with particular wear-resistant SL-pins are used, so longer service life in comparison with hollow pin chains • Transport bars available in required lengths with 1mm graduations • Different shapes for bar ends avaiable – for example nipples made of aluminium or plastic • Freely selectable distance between the bars • 3/4 inch chain also available in curved side design (M 128 ASB) or maintenance free*

Request for a quoteResults for

Hollow pin chains - Import exportNumber of results

10 ProductsCountries

Company type