- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hot strips

Results for

Hot strips - Import export

PETROPLAST GMBH

Germany

TEAR TAPE/TEAR STRIPS Self-adhesive tear tape and tear strips with a hot-melt coating for food and non-food packaging, for example for cheese triangles, CDs and tobacco products. The tear tape can be supplied in several versions (e.g. printed) as required. Different standard colours and widths can also be delivered directly from stock. Do you have any questions about tear tape? We are here to help and will gladly advise you on the right tear tape for your product. Tear tape/tear strips – the facts: Use for food and non-food packaging Self-adhesive or with a hot-melt coating Also available printed and/or dyed as required Available directly from stock in several standard colours and widths

Request for a quote

DUTCH SCRAP RECYCLING B.V.

Netherlands

Buyers can contact us for obtaining Plastic Scrap in bulk quantity. We have been serving in this domain for a long time. We deliver things within the given period. Punctuality and quality are the keywords of our functionality. We source it from reliable vendors. We assort and test the scrap to make sure that the client gets zero defect material. HDPE milk bottle scrap Hdpe flake HDPE Drum in baled HDPE Regrind LDPE Clear film scrap Pet bottle scrap Pet flakes hot washed Green pet strip scrap PC water bottle scrap PC Water bottle regrind PC CD / DVD METALIZED AND CLEAR SCRAP Bopp film roll scrap pp jumbo back scrap PP super sack scrap PP big rope scrap

Request for a quote

PLASTFIT PVC PROFILE

Turkey

Intufit® strips prevent cold-hot smoke from spreading when they reach a specified temperature during the fire. As Intufit® strips expand 20 times larger than their initial shape during a fire, they provide fire retardant properties. As a result of the self-adhesive applied on steel fire-resistant doors.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

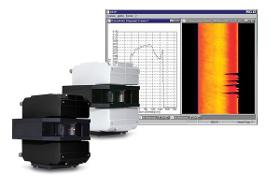

The ES Thermal Imaging System for Sheet Extrusion from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and product. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized applications and industrial environments. The ES Thermal Imaging System is ideal for continuous web applications such as hot strip mills, continuous casting, glass wool production, laminating for both glass and plastics and more. MP Linescanner With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The containers are picked up by the in feed star wheel and transferred to the container table. The container rotation begins when they are positioned between container plates and centering bells. The speed of the feed roller is adjusted to the required label length for continuous web tension. A standard threading unit ensures optimal film feed. In the cutting unit, the labels are precisely cut while a PLC command and servo-motor provide an exact cut-off point. Two narrow strips of hot melt glue the labels together, which are applied by a heated glue roller to the leading and trailing label edges. The label with the glue strip on its leading edge is transferred to the container. This glue strip ensures an exact label positioning and a positive bond. As the container is rotated during label transfer, labels are applied tightly. Gluing of the trailing edge ensures proper bonding. Process: In feed bottle → pre-position →label cutting → gluing → labeling → label by press out → finish

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES : Thickness tolerances according to EN 10051 for nominal widths. WIDTH TOLERANCES: Width tolerances according to EN 10051 for nominal widths Other, closer dimensional tolerances on request. EDGE CAMBER TOLERANCES: Sag tolerances according to EN 10051 for pickled hot-rolled strips will be agreed when placing the order. RIPPLE - LONGITUDINAL FLATNESS: The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm on 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES : Thickness tolerances according to EN 10051 for nominal widths. WIDTH TOLERANCES: Width tolerances according to EN 10051 for nominal widths Other, closer dimensional tolerances on request. EDGE CAMBER TOLERANCES: Sag tolerances according to EN 10051 for pickled hot-rolled strips will be agreed when placing the order. RIPPLE - LONGITUDINAL FLATNESS: The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm on 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES : Thickness tolerances according to EN 10051 for nominal widths. WIDTH TOLERANCES: Width tolerances according to EN 10051 for nominal widths Other, closer dimensional tolerances on request. EDGE CAMBER TOLERANCES: Sag tolerances according to EN 10051 for pickled hot-rolled strips will be agreed when placing the order. RIPPLE - LONGITUDINAL FLATNESS: The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm on 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

FINISHES: SURFACE QUALITY PROPERTIES OF THE COATINGS GALVANISED STEEL according to EN 10142 Check our website for coating mass, coating finish, surface quality and protection surface treatment. If the customer does not require the surfaces to be oiled and/or chemically passivated, this must be clearly indicated when requesting the quote and placing the order. THICKNESS TOLERANCES Thickness tolerances according to EN 10143 for nominal widths. WIDTH TOLERANCES Tolerances on wide strips obtained by longitudinal cutting of a width of less than 600 mm.According to Standard EN 10143 of: w < 125; 125 w < 250; 250 w < 400; 400 w < 600. Other, closer dimensional tolerances under a commercial agreement. SAG TOLERANCES Edge curve tolerances under commercial agreement

Request for a quote

VINCO

Spain

FINISHES: SURFACE QUALITY PROPERTIES OF THE COATINGS GALVANISED STEEL according to EN 10142 Check our website for coating mass, coating finish, surface quality and protection surface treatment. If the customer does not require the surfaces to be oiled and/or chemically passivated, this must be clearly indicated when requesting the quote and placing the order. THICKNESS TOLERANCES Thickness tolerances according to EN 10143 for nominal widths. WIDTH TOLERANCES Tolerances on wide strips obtained by longitudinal cutting of a width of less than 600 mm.According to Standard EN 10143 of: w < 125; 125 w < 250; 250 w < 400; 400 w < 600. Other, closer dimensional tolerances under a commercial agreement. SAG TOLERANCES Edge curve tolerances under commercial agreement

Request for a quote

EUROPONTEX IMPORTAÇÂO & EXPORTAÇÂO

Portugal

- Wide range of steel grades: structural, cold forming, HSLA, etc. - In coils or cut-to-length - Standard os curtomized sizes

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Copper Strips are manufactured from highly conductive and thin thickness. They are windly used in automotive industry; radiators, cable industry, electronic and electrical industries; decorative components and Building industry: roofings.etc. Coper Strips are ideally used in applications where the salt content in the soil is very high, with a width of 5mm to 160mm, Thickness of 0,10mm to 10mm. Copper strips are produced, hot and cold rolling , by extruded OF busbars and they are accordıng with TS EN 1652, DIN EN 1652, DIN EN 13599 also EN 13601

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Copper Strips are manufactured from highly conductive and thin thickness. they offer great resistance to corrosion.They are widly used in automotive industry; radiators, cable industry, electronic and electrical inustries; decorative components and Building inustry: roofings.etc. Coper Strips are ideally used in applications where the salt content in the soil is very high, with a width of 10mm to 160mm, Thickness of 0,20mm to 6mm. Copper strips are produced, hot and cold rolling , by extruded busbars and they are accordıng with TS EN 1652, DIN EN 1652, DIN EN 13599

Request for a quote

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

OBO has reinvented its tried-and-trusted welded cable ladders and optimised them for use in industry. Thanks to their special design and intelligent rungs, they can offer even more installation space and flexible mounting options – for vertical or horizontal installation. Not only the innovative welding of the new rung, for which a patent has been applied, but its well-thought-out hole pattern are also perfectly tailored to the requirements of all kinds of industrial installations. The special feature: The rungs can be filled on both sides using the matching clamp clips. This means that the installation space can be fully exploited, so that frequently the narrower ladders are sufficient, which reduces costs. The range of materials is not forgotten. The ladders are available in strip galvanised, hot-dip galvanised and A2 and A4 rustproof stainless steel versions. In addition, the new ladders can be powder-coated.

Request for a quote

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

RAIL SYSTEMS Rail systems from OBO The robust rail systems are used worldwide together with numerous other OBO products. For example, as suspension for cable support systems, as fastening rails for bracket clips for cable routing or as mounting rails. In addition to different load classes, the rails are of course also available in various widths and with a selection of hole patterns. Depending on the application, the rail range is available in two surfaces: strip galvanized and hot-dip galvanized, as well as in stainless steel grades V2A and V4A. Different load ranges for OBO's rail systems OBO's tried-and-tested rail system is now even more clearly sorted. At a glance, you can now choose from three load ranges: light, medium and heavy. The matching accessories can also be found directly in the selection aids. This makes it easy to choose the right products for the job.

Request for a quote

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

RAIL SYSTEMS Rail systems from OBO The robust rail systems are used worldwide together with numerous other OBO products. For example, as suspension for cable support systems, as fastening rails for bracket clips for cable routing or as mounting rails. In addition to different load classes, the rails are of course also available in various widths and with a selection of hole patterns. Depending on the application, the rail range is available in two surfaces: strip galvanized and hot-dip galvanized, as well as in stainless steel grades V2A and V4A. Different load ranges for OBO's rail systems OBO's tried-and-tested rail system is now even more clearly sorted. At a glance, you can now choose from three load ranges: light, medium and heavy. The matching accessories can also be found directly in the selection aids. This makes it easy to choose the right products for the job.

Request for a quote

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

RAIL SYSTEMS Rail systems from OBO The robust rail systems are used worldwide together with numerous other OBO products. For example, as suspension for cable support systems, as fastening rails for bracket clips for cable routing or as mounting rails. In addition to different load classes, the rails are of course also available in various widths and with a selection of hole patterns. Depending on the application, the rail range is available in two surfaces: strip galvanized and hot-dip galvanized, as well as in stainless steel grades V2A and V4A. Different load ranges for OBO's rail systems OBO's tried-and-tested rail system is now even more clearly sorted. At a glance, you can now choose from three load ranges: light, medium and heavy. The matching accessories can also be found directly in the selection aids. This makes it easy to choose the right products for the job.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

RAIL SYSTEMS Rail systems from OBO The robust rail systems are used worldwide together with numerous other OBO products. For example, as suspension for cable support systems, as fastening rails for bracket clips for cable routing or as mounting rails. In addition to different load classes, the rails are of course also available in various widths and with a selection of hole patterns. Depending on the application, the rail range is available in two surfaces: strip galvanized and hot-dip galvanized, as well as in stainless steel grades V2A and V4A. Different load ranges for OBO's rail systems OBO's tried-and-tested rail system is now even more clearly sorted. At a glance, you can now choose from three load ranges: light, medium and heavy. The matching accessories can also be found directly in the selection aids. This makes it easy to choose the right products for the job.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Hot rolled steel strip is produced from a part of a metal sheet (coil) on a guillotine installation by shearing or hot rolling necessary for the manufacture and production of various flat fastening structures, tools, components and assemblies, while substantially alleviating our labor costs, energy costs and time for the preparatory process, and cutting the sheet. Overall dimensions of a flat workpiece length up to 6 meters, thickness 3 20 mm LLC "Company STALEVAR" can produce hot rolled strip , according to the specified conditions and overall dimensions of the buyer. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

FRIEDR. GUSTAV THEIS KALTWALZWERKE GMBH

Germany

Stainless, acid-resistant, heat-resistant: no wonder that many clients rely on our THENOX® precision steel strips. The premium flat product made of corrosion-proof stainless steels is produced from hot-rolled steel strip in a cold rolling process. In detail: Through the main alloy element, chrome, a protective layer of chrome oxide is formed on the surface of the austenitic, ferritic and martensitic steels: this gives the material a permanent metallic appearance. Even in chemically aggressive substances. Other carefully alloyed elements, such as nickel, molybdenum and titanium, improve the corrosion resistance and – depending on the alloy – give the different types of steel the required technological properties: for instance good deep-drawing, bending or punching capabilities, or increased elasticity values. We roll steel in thicknesses from 0.05 to 1.50 mm with widths from 3 to 650 mm.

EURASIA METAL GMBH

Germany

Production standart : EN 10051 FOR HR MATERIALS - S235 JR, S275 AND S355 QUALITIES EN 10139 FOR CR MATERIALS - DC 01 , ST 12 QUALITIES EN 10025 – 1

Request for a quoteResults for

Hot strips - Import exportNumber of results

22 ProductsCountries

Category

- Industrial cabling (6)

- Steel sheets and strips (6)

- Cold rolled steel strips (2)

- Copper sheets and bands (2)

- Bottling and filling - machinery and equipment (1)

- Fire protection equipment (1)

- Galvanization - steels and metals (1)

- Infrared tubes (1)

- Scrap iron - salvaging and recycling (1)

- Steel & Metals (1)

- Steel, carbon (1)