- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hydraulic regulating equipment

Results for

Hydraulic regulating equipment - Import export

CEC YUH BAW CO., LTD.

Taiwan R.O.C.

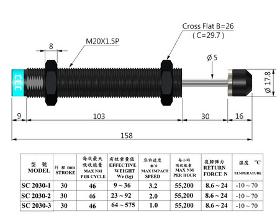

Non-adjustable shock absorber, thread M 20 pitch 1.5 mm, stroke 30 mm.

Request for a quote

CEC YUH BAW CO., LTD.

Taiwan R.O.C.

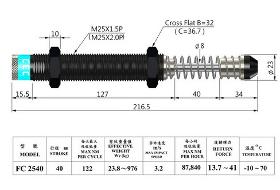

Thread M 25, pitch 1.5 ( 2.0 ) mm, stroke 40 mm.

Request for a quote

AHP PLASTIK MAKINA

Turkey

maximum accuracy, a long service life and a userfriendly system, combined with flexibility Highprecision pressure regulation, selectively regulated input pressure in each Line All metal components that come in contact with the medium is brass ans SS304 Quick system calibration easily by the operator and calibration data saved in the controller modules Convenient operation, evaluation of results and clear visualization via Labview and windows based software Operator access to all important settings from the front panel Each station can be individually isolated from the supply pressure for service purposes PLC based control of the pressure channels Pressure gauge for checking each line actual pressure

Request for a quote

EISELE GMBH

Germany

- Whitworth pipe thread- Chambered O-ring - Sealing NBR - Material brass nickel-plated - Temperature range -4 to 176 °F (-20 to +80 °C) - Working pressure range -14 to 232 psi (-0.95 to 16 bar) - Swiveling, but not designed for steady motion of the tube

Request for a quote

EISELE GMBH

Germany

- Whitworth pipe thread- Chambered O-ring - Sealing NBR - Material brass nickel-plated - Temperature range -4 to 176 °F (-20 to +80 °C) - Working pressure range -14 to 232 psi (-0.95 to 16 bar) - Swiveling, but not designed for steady motion of the tube

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TITAN MACHINERY

United Kingdom

Hydraulic station manufacturing refers to the process of designing, assembling, and producing hydraulic power units or stations. These units are essential components of hydraulic systems used in various industrial applications, including manufacturing, construction, agriculture, and more. Hydraulic stations provide the necessary power and pressure to drive hydraulic machinery, such as cylinders, motors, and valves. The manufacturing process of hydraulic stations involves several key steps: Design and Engineering: The process begins with the design and engineering of the hydraulic station. This includes specifying the required flow rate, pressure, and functionality based on the application's needs. Engineers create detailed schematics and plans for the hydraulic station. Component Selection: Manufacturers carefully select hydraulic components such as pumps, motors, reservoirs, valves, filters, and hoses based on the system's specifications. The chosen components should be durable.

Request for a quote

TECHNOPARK IMPULSE LLC

Russia

Impulse vibratory compactor attachments for backhoe loaders and excavators are designed for soil compaction during the construction and repair of roads, buildings and special facilities. Impulse V-Series hydraulic compactors embody the best modern solutions. Reliable and affordable: Impulse compactors have a straight upper body, a modified shock absorber shape with an angle of 90 ° and a redesigned vibration damper unit using a one-piece eccentric with an integral attachment to the compaction plate. Thanks to innovations, productivity has increased by 20% compared to the previous generation of compactors. Considering the affordable price and minimal service costs, Impulse compactors are the best solution in their market segment

Request for a quote

KONTAKT LLC

Ukraine

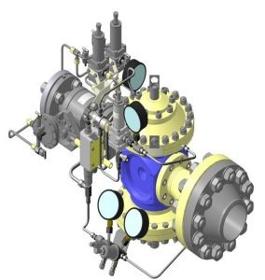

The gas pressure regulator of the RTBK type is designed for automatic regulation of gas pressure “after itself” at the facilities of high pressure gas pipelines, such as gas distribution stations, gas treatment and dehydration plants, gas fields, compressor stations, etc. The operating medium is natural gas and other gases that are not aggressive to regulator materials. Inlet working pressure: from 12 to 100 bar Output working pressure: from 1 to 12 bar Depending on the order, the modular regulator of the RTBK type can include the following elements: General-purpose body based on which the modular type regulator is built. Active module. Monitor module. Built-in shut-off valve. Shut-off valve as a separate element connected in series with the regulator body. Noise reduction module. And other technical combinations of modules and components. More information on our website.

Request for a quote

WEINLICH GMBH & CO. KG

Germany

The MP Computer is a comfortable, comprehensive and easy-to-handle evaluation, display and control unit for different types of engine test beds. Its clear and ergonomic arrangement fascilitates the work with the test bed. Desired loads can be adjusted quickly and easily. Specialists are not required. Many optional additional functions increase enlarge the comfort of the MP Computer. Maintaining permanent accuracy of torque measurement is facilitated by a semi-automatic calibration routine. Existing engine/motor test beds can be modernized by an MP Computer. Examples of optional additional functions: - Automatic gravimetric determination of the specific fuel consumption. - Several possibilities of output and documentation of measured values. - Acquisition of non-electric and electric measuring values on combustion engines, electric machines, etc. - Special functions required by certain measuring tasks.

Request for a quoteResults for

Hydraulic regulating equipment - Import exportNumber of results

10 ProductsCompany type