- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- in-mould labelling (iml)

Results for

In-mould labelling (iml) - Import export

DECAPAC

Belgium

In Mould Labeling is a decoration method where the packaging and the label merge together during the injection moulding process. This way, illustrations and information can be applied to plastic packaging. The result is a decoration with outstanding picture quality which is inseparable from the packaging. IML is the solution to make your products stand out !

Request for a quote

PLASTOBREIZ & PLASTOLOIR

France

Our design team researched how you could cover your thermoformed packaging using sleeve technology or a heat-shrinkable sleeve. The sleeve provides your packaging with an elegant and sophisticated visual effect, as well as a 360° communication area. This technology applies to specific container shapes and is an alternative to IML (in-mould labelling).

Request for a quote

TEMAS GROUP EXPORT PARTNERS

Turkey

Soft cheese Chocolate cream Hazelnut spread Yogurt Our company, Ice Cream, operates as a solution partner for its customers in various sectors. The company specializes in customer-specific product design, IML (In Mould Labelling) design, and mould making, and strives to ensure maximum customer satisfaction through its professional team’s commitment to quality without any compromises. In addition to these sectors, it also provides customers with alternative solutions to support their R&D studies.

Request for a quote

MARSI GROUP D.O.O.

Slovenia

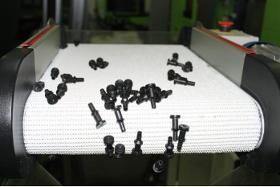

MASS PRODUCTION OF PLASTIC PARTS Our equipment enables us to develop and produce high quality plastic parts. We have many years of experience with mass production of plastic parts – we produce batches up to 100 Mio pcs per year. Fully automated manufacturing process enables us to produce high quality products, without complaints. IML INJECTION MOLDING IML (In Mold Labeling) is an injection molding technology that automatically inserts labels (special foils) into the injection molding tool. The IML injection molding method is extremely effective when the customer wants to create a high aesthetic appearance/appeal of the product at optimal cost. 2K INJECTION MOLDING 2K injection molding is two-components injection molding performed by rotary tool. The future of injection molding of composite plastic products lies in two-components injection molding. We offer injection molding on Krauss Maffei 2K machine with clamping force of 200t, 3x 120 rotary table and SEPRO robot.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIMCO-ION EUROPE

Netherlands

The IML Spider is a versatile electrode for direct charging for IML applications. It consists of a IML Spiderblock with built-in resistors to prevent accidental sparking. The IML Spider Block has 8 output ports, withresistors per port, for connection of up to 8 flexible charging electrodes. An additional output port isprovided for daisy chaining complementary IML Spider Blocks. All connection ports are equipped with quick connect plugs. Electrodes are available in lengths of 300 and 500 mm and a special 500 mm long one that can be tailored during installation by use of a special tool. Interconnection cables are available in lengths of 0,5 , 1 , 2 and 3 metres. Connection cable for use with the CM type generator are standard 2 , 5 and 10 metres long. The IML Spider can be used for IML applications in conjunction with IML generators with a maximum output of 18 kV.

Request for a quote

SIMCO-ION EUROPE

Netherlands

The CMME is a small profile footprint charging generator specially designed for IML applications. The unit has fully integrated high voltage parts and only needs a 24V DC supply. The housing is compact, robust and only weighs 480 grams which makes it perfect for end of arm mounting in IML pick and placehandling systems. It can easily withstand the high G-forces occurring during the IML process. The CMME has a unique (patented) cyle OK feature. A signal will become active when the label(s) have accumulated enough electrostatic charge indicating that the charging is finished. This signal can be used by the machine interface to decide to stop charging. A second stage in the cycle OK signal will indicate that the charge on the mandrell has dropped below asafe level to start moving the mandrell out of the mould.This innovative feature completely eliminates the guess work and experimental setup for each individualIML application, and when changing product or label.

Request for a quoteResults for

In-mould labelling (iml) - Import exportNumber of results

8 ProductsCompany type