- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial electric furnaces

Results for

Industrial electric furnaces - Import export

REINHARDT GMBH

Germany

Since decades, Reinhardt ovens “Made in Germany” are working day by day all over the world and are estimated by their reliability and long life time. Adapted to your requirements, a Reinhardt oven delivers the best results that are completely designed to your production process. In the temperature range up to 650° Celsius Reinhardt offers the best solutions for almost all requirements, for heating, tempering, drying, hardening, etc. all designed to your space conditions. All heating technologies, from electrical, direct or indirect gas, oil can be applied. Together with the customer, the Reinhardt industrial ovens are integrated into the production flow. In a classical batch oven, hood oven or pass through oven all thermal processes can be applied with the highest accuracy. Requirements such as lifting doors, charging carrier, transport and handling systems can be easily applied.

Request for a quote

BTF

Belgium

Electric or gas-fired furnaces, with dimensions and specificities according to your needs Top quality insulation using fibre materials and lightweight insulation bricks Precisely determined power rating Sturdy, precision construction Door fitted on adjustable hinges and fitted with seal Simple and rapid closing system (locking options) Wound resistances, mounted on porcelain tubes to ensure homogeneous radiation Flue installed in the vault & inspection hatch in the door Temperature control system (programmable controller adapted according to the size of the oven and your cooking)

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

In-line conveyor ovens: Pallets pass through the oven one after the other. Automatic batch ovens: The oven is charged with pallets while kept at a temperature below the gelation temperature. After the last pallet has been loaded, the temperature cycle is started for the whole lot. The oven is emptied in a rapid process after the complete temperature profile has been run through. Stack ovens: Pallets are loaded into the oven. When each row has been filled, all the rows of pallets are lifted up by one level. When one row of pallets has reached the uppermost position of a temperature range, it is pushed into the next temperature zone and from here is lowered down in fixed time cycles and unloaded. Serpentine conveyor ovens: Pallets are loaded into the oven in fixed time cycles and pass through the individual temperature zones.

Request for a quote

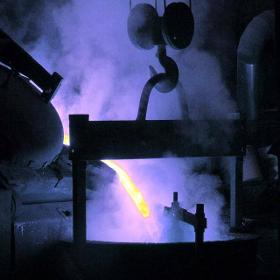

INDUCTION FURNACE SERVICES LIMITED

United Kingdom

Zajmujemy sie naprawami instalacji do wytapiania Inductotherm, usuwaniem wszelakich usterek w jesnostkach mocy VIP. Wykonujemy okresowe przeglady serwisowe. Posiadamy w ofercie szeroki zakres części zamienych. Dojazd do klienta na terenie całej Europy. Krzysztof Kicek Tel. 0044 7726 443392

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRAGMA BUYING SRLS

Italy

hot dip galvanizing plants, we are one of those few companies who engineer and design on their own know how and realize by themselves all components and equipments, making up lines of production. Moreover, we like to underline that we guarantee and assure the maximum of the efficiency for what the assistance after sale is concerning. In this connection and in case you are looking for a Company who can support you in designing of new galvanizing plants or to improve the performance of your existing plant please do not hesitate in contacting us. Our production : • Galvanizing furnace; • Dryers; • Enclosures on the galvanizing furnaces; • Complete enclosures on pretreatment area; • Aspiration and filtering units for galvanizing fumes; • Pretreatment tanks in PP; • Heat exchangers to heat the pretreatment tanks; • Aspiration and neutralization units for acid fumes; • Heat recovery sistems; • Adjustable height jigging stations; https://www.youtube.

Request for a quote

TAMPOPRINT GMBH

Germany

TAMPOPRINT pad printing and fully automatic laser machines meet the highest quality requirements when used in multi-shift operation with high throughput speed. Highest precision of the print image registration on convex, round or flat parts by using the pad printing process, one to multicolor, or by using the ALFALAS® laser marking process goes without saying and meets the high standards for these industrial products. Process monitoring by using the latest camera systems will secure your production. We make markings, scales and decorations possible where other processes reach their limits.

Request for a quote

XIAMEN ARABELT TRADING & CONSULTING CO.,LTD

China

At ARABELT, we simplify this process by offering a comprehensive range of electric power products: - Transformers - Circuit Breakers - Switchgear and Distribution Panels - Electrical Cables and Wires - Electrical Substations - Power Generation Equipment - Energy Storage Solutions - Smart Grid Solutions - Power Quality and Monitoring Equipment - Consultation and Project Management

Request for a quoteResults for

Industrial electric furnaces - Import exportNumber of results

9 Products