- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial furnaces and ovens

Results for

Industrial furnaces and ovens - Import export

BTF

Belgium

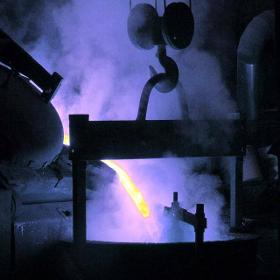

Industrial furnaces BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, …

Request for a quote

BTF

Belgium

BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, … Furthermore, BTF designs and manufactures furnaces for performing fire resistance testing in approved laboratories, for the certification of materials. These furnaces must provide rates of temperature rise complying with the ISO standards.

Request for a quote

BTF

Belgium

Industrial furnaces BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, …

Request for a quote

BTF

Belgium

Industrial furnaces BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, …

Request for a quote

BTF

Belgium

Industrial furnaces BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, …

Request for a quote

BTF

Belgium

Industrial furnaces BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, …

Request for a quote

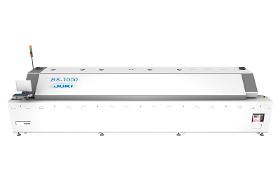

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven With its 10 heating zones and 2 cooling zones JUKI’s RS 1000 helps create even ambitious profiles and improve towards a high throughput of printed circuit boards respectively. Top flexibility is therefore guaranteed for future applications as well. In spite of a higher count of heating zones, the energy consumption is low.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven JUKI’s RS 600 6 zone reflow soldering oven is the space saving and inexpensive solution for the numerous standard SMT soldering tasks. Taking up a small amount of floor space and having low energy consumption, the machine has all the advantages of a larger reflow soldering oven such as perfect thermal properties as well as comprehensive equipment including useful features.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven JUKI’s RS 800 8 zone reflow soldering oven embodies the best compromise between cost and effectiveness, floor space and energy consumption. With its 8 zones even complex soldering profiles can be constructed. 2 cooling zones ensure a suitable cooling down of the printed circuit boards after the soldering process.

Request for a quote

THERSER (UK) LTD

United Kingdom

Industrial furnaces and ovens form a significant part of Therser UK’s global business. Therser’s skilled and experienced engineering team combined with Therser’s many years’ experience in supplying a range of furnaces to customers around the world who operate in a variety of industries, ensure that you can be confident of the operational and quality benefits a Therser furnace provides, along with our renowned commitment to after sales services such as maintenance and repair services and the supply of a full range electrical, mechanical and insulation spares and replacement parts. Therser UK have successfully supplied furnaces and ovens around the world for applications including Heat Treatment, Aerospace, Foundry and Fabrication. We are also well equipped to develop thermal solutions for new and emerging technologies in close partnership with our customers from the whole industrial spectrum.

Request for a quote

REINHARDT GMBH

Germany

Since decades, Reinhardt ovens “Made in Germany” are working day by day all over the world and are estimated by their reliability and long life time. Adapted to your requirements, a Reinhardt oven delivers the best results that are completely designed to your production process. In the temperature range up to 650° Celsius Reinhardt offers the best solutions for almost all requirements, for heating, tempering, drying, hardening, etc. all designed to your space conditions. All heating technologies, from electrical, direct or indirect gas, oil can be applied. Together with the customer, the Reinhardt industrial ovens are integrated into the production flow. In a classical batch oven, hood oven or pass through oven all thermal processes can be applied with the highest accuracy. Requirements such as lifting doors, charging carrier, transport and handling systems can be easily applied.

Request for a quote

BTF

Belgium

Electric or gas-fired furnaces, with dimensions and specificities according to your needs Top quality insulation using fibre materials and lightweight insulation bricks Precisely determined power rating Sturdy, precision construction Door fitted on adjustable hinges and fitted with seal Simple and rapid closing system (locking options) Wound resistances, mounted on porcelain tubes to ensure homogeneous radiation Flue installed in the vault & inspection hatch in the door Temperature control system (programmable controller adapted according to the size of the oven and your cooking)

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

In-line conveyor ovens: Pallets pass through the oven one after the other. Automatic batch ovens: The oven is charged with pallets while kept at a temperature below the gelation temperature. After the last pallet has been loaded, the temperature cycle is started for the whole lot. The oven is emptied in a rapid process after the complete temperature profile has been run through. Stack ovens: Pallets are loaded into the oven. When each row has been filled, all the rows of pallets are lifted up by one level. When one row of pallets has reached the uppermost position of a temperature range, it is pushed into the next temperature zone and from here is lowered down in fixed time cycles and unloaded. Serpentine conveyor ovens: Pallets are loaded into the oven in fixed time cycles and pass through the individual temperature zones.

Request for a quote

INDUCTION FURNACE SERVICES LIMITED

United Kingdom

Zajmujemy sie naprawami instalacji do wytapiania Inductotherm, usuwaniem wszelakich usterek w jesnostkach mocy VIP. Wykonujemy okresowe przeglady serwisowe. Posiadamy w ofercie szeroki zakres części zamienych. Dojazd do klienta na terenie całej Europy. Krzysztof Kicek Tel. 0044 7726 443392

Request for a quote

PRAGMA BUYING SRLS

Italy

hot dip galvanizing plants, we are one of those few companies who engineer and design on their own know how and realize by themselves all components and equipments, making up lines of production. Moreover, we like to underline that we guarantee and assure the maximum of the efficiency for what the assistance after sale is concerning. In this connection and in case you are looking for a Company who can support you in designing of new galvanizing plants or to improve the performance of your existing plant please do not hesitate in contacting us. Our production : • Galvanizing furnace; • Dryers; • Enclosures on the galvanizing furnaces; • Complete enclosures on pretreatment area; • Aspiration and filtering units for galvanizing fumes; • Pretreatment tanks in PP; • Heat exchangers to heat the pretreatment tanks; • Aspiration and neutralization units for acid fumes; • Heat recovery sistems; • Adjustable height jigging stations; https://www.youtube.

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Tunnel type ovens are convection ovens which allows to electrostatic powder coated work pieces to be cured usually around at 180-200°C in 10 minutes, are used in the powder coating systems. Curing oven length is calculated according to the conveyor speed in order to achieve polymerization and curing of the work piece quantities per shift. The powder coating ovens are designed by us according to the shape, quantity and weight of the product to be cured. These ovens are conveyorised, product inlet and outlets are opened designed accordint to the biggest work piece sizes. Oven can be designed as a tunnel, U, S or W-shaped according to the biggestt work piece and the work shop sizes. Electricity, liquid or gas fuel is used for heating up the ovens.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Industrial furnaces and ovens - Import exportNumber of results

18 ProductsCompany type