- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial milling machines

Results for

Industrial milling machines - Import export

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

FSG INTERNATIONAL MACHINE TOOLS

Italy

Company specialized in 5 Axis Machines Tools used. only hight quality machines from the best brands like DMG MORI, OKUMA, MAZAK, ect.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

- made of steel - with safety housing - desktop machine or stand-alone - incl. CNC control Zero3 - incl. ConstruCAM-3D software - incl. Estlcam software - 16 different sizes available

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Material: SS304 Surface treatment: black anodized Tolerence: N6 and H9 Machining method: cnc turining and milling Usage: Industrial machine

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

The unique construction of spherical roller bearings make them vital for heavy applications. Their performance is consistent even in extreme conditions, as in the case of high-stress environments and / or reduced lubrication. Spherical roller bearings can give a use life equal to twice that of traditional bearings, according to some estimates. Features of spherical roller bearings: ideal for reduced and medium speeds self-aligning and very robust able to bear radial and axial loads in both directions longer use life compared to traditional bearings excellent compensation for misalignments APPLICATIONS: Earth Moving Machinery Agricultural Machinery Fitness machines Steel working machines Marble processing machines Iron and Steel Industry Oil Industry Automatic opening systems Heavy machinery (eg machines for construction and mining) Bottling / filling carousels Steel mills Industrial transmissions Vibrating equipment / machines Vibrating sieves / vibrating screens

Request for a quote

STEEC

France

STEEC is able to carry out milling and micro-milling operations on complex mechanical parts with increasingly finer dimensions and increasingly tighter tolerances. STEEC carries out micro-drilling operations to manufacture not only parts but also very high precision electrodes. That enable all spark erosion micro-drilling and countersinking operations to be performed. Equipped with a stock of high-tech machines and leading edge IT tools, such as the Solidworks software, STEEC is capable of meeting special requirements and providing innovative solutions for each of its customers. The experience gained in other high precision machining technologies has enabled STEEC to develop innovative milling processes that are well recognized in the industrial environment.

Request for a quote

EC PLAZA

South Korea

MIRHO Corporation make an industrial CNC in person in Korea, called G-Aid, also using for education , industry, dental purpose. We are introducing our signature product, Smart Milling Machine G AiD. G AiD is high speed milling machine for more precise machining. It has comparable six features with another CNC. - Control axis : simultaneous 4 Axis - Spindle : Max 30,000RPM 3.6kW - ATC : Tool detect sensor 7ea, Ф6 - Material : Titanium, Industrial Ceramic, Aluminum, Sus, Steel, SiC, Carbon, ALN, Etc. - Motor : AC servo with IP67 absolute system - Working Area : 100*100 mm - Power Requirement : CE, KCs - Weight : 336kg - External Dimensions : 600*780*1800 mm Feature 1 is "Multiple Jig Solution". Features 2 is "Optimized Motion Controller". Features 3 is "Easier User Interface". Features 4 is "High Speed Milling". Features 5 is Automatic Tool Length Measurement". Features 6 is " Optimized Footprint and Low-Cost High Efficiency".

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

WiTEC Basic - the perfect, allrounder machine for the most precise and fastest machining of your sheet materials! Equipped with an FEM optimized machine design, premier precision components, and using powerful Servo Technology, the WiTEC router is capable of achieving top milling speeds and delivering top precision results. Thanks to the combination of Wissner’s innovative and patented hold&press Technology and sophisticated Vacuum System, you can mill even the smallest parts all the way through the finishing cut-out! No need for any adhesive paper or foil, no need for leaving connector tabs, and no deburring or cleaning is necessary! The ready-finished parts will go directly from the machine table to the end customer!

Request for a quote

VIRMER

Netherlands

Wattsan M4S milling machine with 4 spindles is intended for continuous material processing. Working spindles are changed automatically that significantly facilities the operator’s work. Spindles have power of 6 kW and come with an ER-32 collet chuck. Only one spindle can be in operation at a time. The working area is 1300x2500 mm. The processed material is fastened by the vacuum table. Pneumatic stops and a vacuum table make setting of the material on the table fast and accurate and facilitate double-sided or straight-line processing

Request for a quote

VIRMER

Netherlands

CNC wood milling machine WATTSAN M1 1325. Ideal for rapidly starting production. Despite the fact that the model belongs to the CNC wood router machine for beginners, complex products are made with this machine. WHY YOU SHOULD BUY THIS CNC WOOD ROUTER MACHINE 1) Solid cast iron frame ensures reliable and high processing accuracy. 2) It is possible to complete the machine with a 4th rotary axis. 3) Attractive to entrepreneurs starting their business as it is easy to use and quickly pays off. The Shimpo planetary gears enable the machine to process even hard metals with high constant precision. Heat treatment of the frame relieves stress from the metal - this is done in every Wattsan CNC machine designed to process wood. This ensures long-term operation while maintaining the accuracy and rigidity of the structure. Work area = 1300*2500 mm Spindle power = 4,5 kW Controller = DSP A11 Weight = 690 kg Machine size = 2000*3040*1780 mm

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN A1 1325 is a multi-purpose equipment for engraving, cutting and 3D milling sheets of materials. WATTSAN A1 1325 has a grid type working table of 1300×2500×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. A spindle ER-25 with collet has power of 3 kW, water cooling system. The portal moved by step engine controlled by driver Yako 2405. Frame of the machine is welded from steel profiles construction; weight of the machine is 800 kg. Max speed of movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 24 000 rpm. The machine controlled by NC-Studio control system. We can modernize the machine with the following: vacuum table, DSP controller, Syntec control system; chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN М1 1616 belongs to М1 series, that is considered more technically sophisticated than A1 series and has a massive frame. The frame is more stable and allows process more complex parts. The machine is applicable for cutting of wood, MDF, chipboard, acryl, plexiglas, PVC, aluminum, composite. Using WATTSAN М1 1616 you can also perform a 3D milling. WATTSAN М1 1616 has a grid type working table of 1600×1600×300 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. Max speed of movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 18 000 rpm. The machine controlled by NC-Studio control system. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN A1 1616 is a cost efficient, easy-to-use and multi-purpose equipment. The machine performs a cutting and engraving, also WATTSAN A1 1616 can perform a 3D milling. WATTSAN A1 1616 has working area of 1600×1600×200 mm, spindle ER-25 with power of 2.2 kW, water cooling system. The portal is moved by step engine controlled by driver Yako 2405. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 500kg. Max speed of spindle movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 24 000 rpm. The working table has a T-slot grid plate. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN М1 1313 has a grid type working table of 1300×1300×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. The construction includes a spindle ER-25 with collet and power of 2.2 kW, water cooling system. The portal moved by step engine driver Leadshine 860. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 700kg. Max speed of spindle movement along axis is up to 25 000mm/min, max working speed is 15 000mm/min. Spindle rotation speed can reach 24 000 rpm. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VIRMER

Netherlands

WATTSAN M1 6090 machine has a working field of 600×900×200 mm with a slatted table cover. A spindle with an ER-20 collet chuck and a power of 1.5 kW, together with a water cooling system (for stable operation of the machine) are included in the basic package. The body of the machine is a welded structure made of steel profile, the weight of the machine is 500 kg. The maximum movement speed along the axes is 25000 mm/min, the maximum speed in operation is 15000 mm/min. Spindle speed can reach 25000 rpm. The machine is controlled by NcStudio software. To upgrade this machine, we can install: DSP controller.

Request for a quote

VIRMER

Netherlands

CNC wood milling machine WATTSAN A1 6090. Ideal for rapidly starting production. Despite the fact that the model belongs to the CNC wood router machine for beginners, complex products are made with this machine. WHY YOU SHOULD BUY THIS CNC WOOD ROUTER MACHINE 1) Solid cast iron frame ensures reliable and high processing accuracy. 2) It is possible to complete the machine with a 4th rotary axis. 3) Attractive to entrepreneurs starting their business as it is easy to use and quickly pays off.

Request for a quote

VIRMER

Netherlands

WATTSAN 0609 mini Desktop cnc wood milling machine WATTSAN 0609 mini for processing materials on a small area. Ideal for rapidly starting production. Despite the fact that the model belongs to the cnc wood router machine for beginners, complex products are made with this machine. The rigid frame of the machine and cast iron side posts allow the gantry clearance to be increased up to 450 mm, while the Shimpo planetary gears enable the machine to process even hard metals with high constant precision. Heat treatment of the frame relieves stress from the metal. This ensures long-term operation while maintaining the accuracy and rigidity of the whole equipment.

Request for a quote

VIRMER

Netherlands

Desktop cnc wood milling machine WATTSAN 0404 mini for processing materials on a small area. Ideal for rapidly starting production. Despite the fact that the model belongs to the cnc wood router machine for beginners, complex products are made with this machine. WHY YOU SHOULD BUY THIS CNC WOOD ROUTER MACHINE 1) Solid cast iron frame ensures reliable and high processing accuracy. 2) It is possible to complete the machine with a 4th rotary axis. 3) Attractive to entrepreneurs starting their business as it is easy to use and quickly pays off

Request for a quote

VIRMER

Netherlands

WATTSAN M1 2030 wide-format machine has a large working area of 2000×3000 mm with a slatted table top. The design includes a spindle with an ER-25 collet chuck and a power of 6 kW. An air cooling system and a built-in vacuum cleaner for collecting wood chips and dust are also available for an additional fee. The leadshine 860 stepper motor driver is responsible for moving the portal, the machine is controlled by the operator through NcStudio. The body of the machine is a welded structure made of steel profile, the weight of the machine is 1400 kg. The maximum travel speed along the axes is 25 000 mm/min, the maximum travel speed during operation is 15 000 mm/min. The spindle speed reaches 24 000 rpm. If you want a more upgraded machine, we can install: Vacuum table. DSP controller. Syntec control system. chip removal system. manual auto lubrication. more powerful spindle or additional cutting heads. rotary device for processing cylindrical products. tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN М9 1325 has a working area of 2500х1300х200 mm and a T-slot slatted table. The complete set of the machine includes a water-cooled spindle with the power of 7.5 kW and ER-32 collet chuck. The portal is driven by YASKAWA servomotor and steppers. The milling machine is controlled by an operator through Weihong NCStudio control system. Unlike the junior model, this machine supports the automatic tool change option. The machine body is a welded structure made of steel profile; the weight of the machine is 1500 kg. The maximum travel speed along the axes is 50 000 mm/min; the maximum travel speed during operation is 20 000 mm/min. The spindle speed reaches 24 000 rpm. The machine is controlled by NCStudio software. On request, the machine can be equipped with a vacuum table, a DSP-controller, a Syntec control system, an aspiration system, a more powerful spindle or an additional spindle, a rotary device to process cylindrical objects, and a tool sensor.

Request for a quote

AHP PLASTIK MAKINA

Turkey

Different forms of radius notches can be machined according to various Standards.The notches are at different radius and angles. Micrometer notches at 0.01 sensitivity. Continuous machining is possible with electric motors. 1 TS EN ISO 179-1 A type notch knife is given together with the machine. Notch knives for various Standards(optional); ISO 180 Type A, Type B ISO 179 Type A, Type B, Type C

Request for a quote

NURER MAKINA LTD STI

Turkey

CNC Borverk, often referred to as CNC Boring Mill or CNC Boring Machine, is a specialized type of machining equipment used for enlarging or finishing pre-drilled holes with precision and accuracy. Borverk is the Swedish term for boring, reflecting the origin of this machining process. The CNC prefix stands for Computer Numerical Control, indicating that the machine's movements and operations are controlled by a computer program. CNC Borverk machines are commonly used in industries such as aerospace, automotive, oil and gas, and general manufacturing, where the production of large, complex parts with high precision is required. These machines are particularly suited for machining large workpieces that cannot be accommodated by traditional drilling or milling machines.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The portal milling machine FZ40 compact is designed for the machining of hard materials as well as aluminum. The inherently rigid machine structure allows for simultaneous 5-axis high speed machining. This compact machine, with its solid cast base does not require a foundation. The machine table is integrated into the cast baseplate, which allows up to 16 metric tons of table load. Eight mounting elements of the FZ40 compact reduce vibration – the basic requirement for high accuracy and optimum surface quality. The sidewalls are filled with a special dampening concrete mix to further enhance performance. The machine has a fully enclosed working space with a fixed machine table. The structural sound overhead gantry with a reinforced Z-ram make up the moving masses. By adding our new dynamic milling head VH60, Zimmermann has created a powerful performer. The combination of high strength and rigidity, constant moving masses and dynamic drives, will meet the industries high demands.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The FZ33 compact combines a wide range of applications with excellent price/performance ratio and proven Zimmermann technology. Take advantage of these features for economical machining for a wide variety of parts for Aerospace, Automotive, Tool and Die, as well as many specialty applications. The rigid monolithic structure eliminates special foundations and provides a cost-effective and variable installation in small spaces. Focusing on the power spectrum to machine small and medium size parts, Zimmermann sets new standards and guarantees the user an enormous amount of flexibility and value – in other words, a low business risk due to an attractive cost price, stable machine value and thanks to its flexibility ensured added value.

Request for a quote

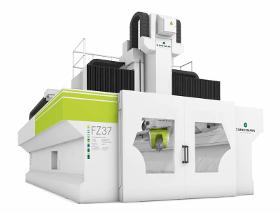

F. ZIMMERMANN GMBH

Germany

Universal metal cutting machine. Designed for highly dynamic machining of different materials. High-speed machining ensures efficient milling results. Advantages: - outstanding price-performance ratio - very broad application spectrum - high-quality universal head for simultaneous machining

Request for a quote

F. ZIMMERMANN GMBH

Germany

With the FZ100 Portal Milling Machine Zimmermann has managed to achieve 6-axis machining using the patented in-house developed M3ABC 3-axis Milling Head. This concept sets new standards in the volume machining of aluminium, composite and model making materials as well as in the High Speed Cutting of steel and cast iron, where conventional 2-axis fork heads with A- and C-axis have long reached their limits in the 5-axis simultaneous machining. Advantages: - Machining four times faster is possible - Perfect quality thanks to the six axes - Highest accuracy possible

Request for a quoteResults for

Industrial milling machines - Import exportNumber of results

34 ProductsCompany type

Category

- Milling - machine tools (28)

- Bearings - ball, needle and roller (1)

- Engraving, industrial - steels and metals (1)

- Machine tools - metal machining (1)

- Machine tools, metal machining - parts and accessories (1)

- Mechanical transmission - components (1)

- Milling - woodworking machinery (1)

- Testing equipment (1)