- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- iron foundry

Results for

Iron foundry - Import export

AKROMAK METAL DIŞ TIC. LTD. ŞTI.

Turkey

Our core competence is the export of castings. We are able to choose the most suitable manufacturer for your needs. Not only cheap prices, but also the guarantee of the required quality are taken into account.

Request for a quote

VOSSE SP. Z O.O.

Poland

Our last realization - elements of conveyor belt.

Request for a quote

CRAFTMACH ENGINEERED SOLUTIONS INC.

Canada

Pressure Die/ Gravity/Sand/ Investment Casting CraftMach Engineered Solutions Inc. is supplying Grey Iron, Aluminium, Carbon steel, Stainless steel, Ductile Iron, Nickel, Brass, Magnesium, Zinc, Copper and other material Casting parts from 1 lb to 150 lbs from one to 300,000 pcs. We have capacity to produce Die, Gravity and Investment casting parts with capability of making mould, testing, heat treatment, painting and assembly capacity for your casting parts. We are specialized in supplying of complex and intricate shaped castings. We are providing cost effective and innovative solutions to OEM customers in the Automotive Sector, Power Transmission & Insulator Manufactures, Manufacturers of Compressor, Pumps and Valves and Material Handling Equipment. CraftMach Engineered Solutions Inc helps its customers in overcoming their competitors cost challenges by re-engineering the component so that it is a lighter castings, less machining required with guaranteed quality and unbeatable cost.

Request for a quote

BIRMINGHAM INDUSTRIES (UK, INDIA)

United Kingdom

Our A grade maize starch meets the highest standards and is a versatile product that can be applied across a variety of industries such as: •Textiles (sizing, finishing, printing) • Paper and cardboard • Glues and Adhesives • Rubber and foam • Paint fillers and putty • Cosmetics • Detergents • Aluminium and Cast-Iron Foundries • Fireworks • Dry battery cell This multifunctional product can be modified to your needs and our sales team would be more than happy to help you find the starch that fits your industrial requirements.

KUTES METAL

Turkey

-Group 1 Moulding Line : Brand : Georg Fischer Type : Impact Standard IM-S-1 otomatik yatay kalıplama hattı Dimensions : 800 x 600 x 250/250mm Capacity: 120 mold / hour Pooring Unit: Inductotherm Visipour P3 Otomatik Tundish Sand Unit : Georg Fischer Conveyor Systems: Georg Fischer Shakeout: Jöst -Group 2 Moulding Line : Brand : HWS (Heinrich Wagner Sinto) Model : Seiatsu EFA-SD otomatik yatay kalıplama hattı Dimensions : 900 x 700 x 300/300mm Capacity: 120 mold / hour Pooring Unit: HWS Otomatik döküm potası Sand Mixer: Eirich RV24 - 3000 Lt - 78 m3 mold sand / hour Sand Control Unit: QualiMaster AT1 Conveyor Systems: VHV Belt Conveyor, Jöst Vibra Conveyor Stakout : Jöst Cooling Tunnel : Jöst

Request for a quote

KUTES METAL

Turkey

4 pieces of 3 tons capacity Dual-Track Inductotherm Induction Furnace 4 pieces of 5 tons capacity Dual-Track Inductotherm Induction Furnace

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

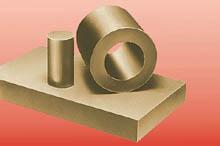

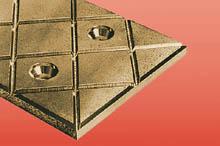

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INSERTEC- INGENIERÍA Y SERVICIOS TÉCNICOS, S.A

Spain

Solutions and engineering services for the design of refractory linings with a focus on equipment performance and efficiency. We work to achieve the highest level of quality with an environmental, health and safety project in both our refractory masses and our prefabricated parts. We offer refractories and precast shapes for a wide range of industrial sectors: Iron foundry Steel foundry Aluminum foundry Cement plants Frites and enamels Heat treatment Steel works Non-ferrous foundry Glass Industry

Request for a quote

UVENTS VENTILATION SYSTEMS

Turkey

Since the impellers are made of aluminium as areas of usage gas plants and acidic places preferred. Aspiration of smoke, iron foundry, cement plants, and paper mills Aspiration of moist and dusty air Industrial buildings, animal farms, greenhouses, garages, sport centers, and parks etc.

Request for a quote

YOUNG FOUNDRY - ANATOLIA CASTING

Turkey

Casting iron products, foundry, manhole, gratings, ductile cast iron tree gratings, cast iron castings, contract manufacturing of cast iron casting, outsource for cast iron casting, subcontractor for cast iron casting, drain covers, Casting Channel, polymer Channel, Ductile Iron U Channel Grid for Rainwater System, Ductile Iron Gully Grating, Ductile Iron Channel Grating Water Grates, Cast Iron Sewer Grating for Sewerage System, Ductile Iron Drain Grid, Ductile iron gratings, Ductile Iron Grate and Frame, Cast Iron Drainage Grid EN124, Rain grate, Ductile Iron Locking Grid, sewer cover, DCI Manhole Cover, Ductile Iron Manhole Cover,Square Manhole Cover,Cast Iron Manhole Cover En124 F900 E600 D400 C250 B125 A15, Access Covers, Gully Grates, Kerb Drainage, Surface Boxes, molding etc hs code 732599

Request for a quoteResults for

Iron foundry - Import exportNumber of results

21 ProductsCategory