- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- labelling machine scales

Results for

Labelling machine scales - Import export

VIA PAPER PC

Greece

Self-adhesive labels for barcode and scales machines.

Request for a quote

FERPLAST SNC

Italy

The TRITONE labeller was made by dividing it into modules, so as to allow use in both horizontal and vertical positions and easy integration into the packaging lines. The control is entrusted to a microprocessor, which manages the pre-separation in mm. and regulates the speed from 0 to 30 mt. min. TECHNICAL FEATURES Stepper motor with variable speed from 5 to 30 mt./min. Maximum label width mm. 100 Minimum label width mm. 20 Maximum label length mm. 300 (higher on request) Minimum label length mm. 20 Label application delay via electronic setting Label application precision mm. 0.5 Label reel with internal diameter mm. 40-76, external mm. 300 max Rewinding roller for silicon paper recovery Variable reading photocell for label stop REFLEX photocell for product detection End of roll alarm (optional) Electronic control unit Switch Stroke counter with zero setting Protection fuses Potentiometer for speed adjustment of labeling head Power supply 220 V 50 Hz. Dimensions mm.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Automatic Wet glue labeling machine is suitable for different round shape bottles/jars/cans/tubes. The machine through double-head design,to achieve rapid labeling or double-sided labeling of cylindrical products; Features: 1.Stick label quality is high,can adjust filament stripes,label flat,no whrinkes,no warping,improve packaging grade; 2.The vacuum labeling along with belt ensures the label stick on the bottle smothly; 3.Adopt enclosed transmission box,fully mechanical transmission,use adhesive to attach various cylinder labels,stable and reliable; 4.The equipment can be used alone,can also be configured with production lines; 5.High degree of automation,paper feeding,glue,labeling,cladding label automatic completion,improve labeling efficiency; 6.It adopts photoelectricity to check the bottles to achieve no bottle no labeling.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-RL Vertical round bottle labeling machine is a self adhesive labeling machine design for round bottle labeling with single label pasting. It is original technology from Italy, high speed labeling and stable.The whole machine frame is adapt 304 stainless steel,servo motor driven the labeling head, PLC control,frequency speed adjust.The labeler can equip with a date coder for printing date, LOT number, also bar code.The detection function is as an option, such as automatically rejection for missing label,automatic warning on missing label, automatic rejection for no date printing etc.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The top labeling machine is the self adhesive labeling machine for pasting labels on top of the products, such as boxes, pouch, caps,lipsticks, or any flat surface of the products. This type of labeler is flexiable, and can bu customized fixing on the exited production line, and easy to move to other place. if change the labeling head direction, then it can be a side labeling machine.With touch screen control panel,make it easier and quicker to adjust various parameter,improve the labeling accuracy and working efficiengy. Label detection electric eye, product detection electric eye and optical fiber amplified adopts famous brands such as Germany SICK, Japan PANASONIC, Germany LEUZE (For transparent sticker) etc

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Process: In feed bottle → pre-position →label cutting → gluing → labeling → label by press out → finish Hot melt OPP glue labeling machine is widely used for different material of container . The label cost is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is the most economical models in cost to make mass production and intergrated operating. The equipment has massively used modularization design concept to make it easy and simple for users to change the bottles. Whether from the replacement of star wheel, guide plate or manual speed adjustment to automatic speed control, for example changing the label is only needed to change the program, the products concept of that the equipment is designed for users is embodied in everywhere.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

it is widely application for the container pasting with two front and back labels, it is one type of self adhesive labeling machine, single and double side labeling is option, using for round container, square and flat container, also carton, boxes ,ect. It is automatic controlled by PLC easy operating. It can change specifications easily. It adopts servo motor, achieved closed loop control low malfunction rate. High efficiency. Double sides labeler we also call it as front and back labeling machine, for it is pasting two labels front and back. Advantages: 1. PLC CONTROL, Automatically check the length of labels 2. Equipped with warning device of insufficient labels, broken labels 3. No bottle, no labeling 4. No labels, no labeling 5.Servo motor control, stable labeling

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

This fully automatic sleeve labeling machine is suitable for various kinds of bottles,like round bottles, square bottles,oval bottles,etc.This machine can automatically feed and cut film,and it can sleeve labels precisely,greatly saving labor and improving work efficiency.The machine can be widely used for beverage bottles,cosmetic bottles,shampoo bottles,etc. The touch screen control panel makes the working parameter is visual,the precise adjustment can be easily achieved according to operation Equipped with high quality electric eye,It can pull film automatically,it is more convenient and easier to operate the machine. The bottle separating component can help to separate bottle and adjust bottles distance,ensure the bottle can be labeled in order,improve the labeling effect. Rotary knobs are designed for adjusting the position of different mechanisms, make sure the machine can sleeve label precisely.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

This fully automatic sleeve labeling machine is suitable for various kinds of bottles,like round bottles, square bottles,oval bottles,etc.This machine can automatically feed and cut film,and it can sleeve labels precisely,greatly saving labor and improving work efficiency.The machine can be widely used for beverage bottles,cosmetic bottles,shampoo bottles,etc. The touch screen control panel makes the working parameter is visual,the precise adjustment can be easily achieved according to operation Equipped with high quality electric eye,It can pull film automatically,it is more convenient and easier to operate the machine. The bottle separating component can help to separate bottle and adjust bottles distance,ensure the bottle can be labeled in order,improve the labeling effect. Rotary knobs are designed for adjusting the position of different mechanisms, make sure the machine can sleeve label precisely.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-HL Automatic horizontal Labeling machine is designed for the vial bottles and container such as ampoul, blood tubes. It adopts horizontal transmission and horizontal labeling to increase stability and improve labeling efficiency. The label can be printed with the production date, batch number and spray bar code. It can be equipped with inkjet printer to the conveyor belt, which can print the production date, batch number, bar code and other information on the product before or after labeling. Automatic horizontal round bottle labeling machine is suitable for labeling on the circumferential surface of round bottles, can be labeled single label and double label, the spacing between the front and back double standards can be flexibly adjusted, such as gel water round bottle, food round can and other labels, widely used in cosmetics, food, medicine, disinfectant water and other industries

Request for a quote

CDA

France

The Ninon Down, an automatic linear labeller, is specifically designed to apply a single label to the bottom of various product shapes, including square, cylindrical, conical, or oval items (bottles, jars, vials, etc.). Equipped with a timing system, it ensures rapid, precise, and efficient product labelling, accommodating a speed of up to 80 products per minute. The Ninon Down stands out for its user-friendly design and control through an intuitive touch screen. Thanks to its versatile application, this linear automatic labeller can be adapted to various sectors, including: Cosmetics and hygiene (soap, shower gel, shampoo, etc.), Food processing (condiments, oil, vinegar, vegetable and fruit jars, etc.), Paint and varnish (buckets, pots, cans, etc.), Chemicals (cleaning products, household items, solvents, detergents, etc.).

Request for a quote

CDA

France

CDA’s Ninon Side facilitates automatic adhesive labelling on the ribs of square, rectangular, and oval products. Equipped with parallel side labelling stations, the Ninon Side simultaneously applies two labels at a speed of up to 60 products per minute. This linear adhesive labelling machine is versatile and suitable for various sectors of activity: Cosmetics and hygiene (shampoo, shower gel, soap, cream, body oil, etc.), Food industry (vinegar, oil, sauce, fruit juice, syrup, honey, jam, marmalade, mustard, spices, etc.), Chemistry (detergent, solvent, household products, motor oil, etc.), Paint and varnish (pots, drum, etc.).

Request for a quote

CDA

France

The CDA Ninon Konic is an automatic linear labelling machine designed to apply up to three labels to all conical products, including jars, bottles, cans, and buckets, at a speed of up to 40 products per minute. This linear labelling machine easily accommodates various formats of conical products in a straightforward and efficient manner, eliminating the need for material changes. The Ninon Konic from CDA finds applications across diverse industries, such as cosmetics (perfume, cream, skincare, soap), food processing (sauce, jam, marmalade, honey, fruit juice, mustard, olive oil, vinegar), chemistry (cleaning and household products, detergents, solvents, motor oil), and paint and varnish (pots, buckets, cans). This machine seamlessly integrates into a comprehensive packaging line.

Request for a quote

CDA

France

CDA's Ninon 1500/2500 is an automatic labelling machine designed for applying up to four labels to a wide array of cylindrical products, including bottles, jars, buckets, cans, tins, and vials. Tailored for medium and large-scale productions, the Ninon 1500/2500 employs a timing system to ensure swift, precise, and efficient product labelling, achieving speeds of up to 50 products per minute. The inclusion of a product accumulation table at the conveyor exit enhances operator convenience. Versatile in its applications, the Ninon 1500/2500 can be used independently or integrated after an automatic filler or capper. It seamlessly fits into complete packaging lines.

Request for a quote

CDA

France

The CDA Essential represents an automatic labelling solution specifically crafted for the wine industry. Tailored to meet the demands of wine bottle labelling, this machine adeptly applies up to two labels – a front label and a back label – using the precise 3-point labelling technique. Furthermore, the CDA Essential offers the capability to crimp both metal and PVC capsules. With an efficient pacing system in place, the labelling process is swift, enabling the labelling of up to 800 bottles per hour. This labelling machine stands out for its user-friendly design and swift adaptability, requiring no additional equipment for accommodating various bottle sizes, ranging from half bottles to Magnums. Facilitating ease of operation, an intuitive touch screen simplifies the adjustment settings for seamless functionality.

Request for a quote

CDA

France

CDA's Solo 1500/2500 comprises automatic labelers designed to apply a single label to a diverse range of cylindrical products, including bottles, jars, buckets, cans, and flasks. Primarily designed for medium and large-scale productions, the Solo labeler features a spacing system to ensure consistent spacing between labeled products. Utilizing a 3-point technique at the labeling station, it delivers fast, precise, and efficient application of pressure-sensitive labels. The Solo labeler can achieve speeds of up to 50 products per minute, dependent on the product and label formats. This automatic labelling machine from the Solo 1500/2500 range offers versatility, making it suitable for standalone use or integration into existing complete packaging lines. It can also be seamlessly incorporated after an automatic filler or a capper/screwer.

Request for a quote

CDA

France

CDA's Cap System is a versatile machine designed for dispensing and crimping capsules or foils, catering to various bottle formats. This high-speed automatic crimping machine boasts an impressive capacity, reaching up to 2500 bottles per hour, depending on the chosen options and product format. Equipped with a conveyor, a capsule dispenser, and one or two crimpers as needed, the Cap System incorporates an intuitive touch screen for seamless machine management and configuration. With its user-friendly design, the CDA Cap System seamlessly integrates into diverse production lines and pairs effortlessly with CDA automatic labelling machines.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CDA

France

The CDA Lea machine stands as an automatic labelling solution meticulously crafted for the wine industry. This specialized machine adeptly applies up to four labels (front label, back label, neck label, and medal) to wine bottles and facilitates the crimping of metal and/or PVC capsules. With a pacing system in place, the Lea machine ensures swift and efficient bottle labelling, boasting a capacity of up to 2000 bottles per hour. Noteworthy for its user-friendly operation and seamless adaptability, this automatic labelling machine can swiftly adjust to various wine bottle sizes, ranging from half-bottles to Magnum, without requiring additional equipment. Ideal for integration into bottling lines, the CDA Lea machine is a versatile choice for the wine industry.

Request for a quote

CDA

France

CDA's Flat Ninette is a semi-automatic adhesive labeling machine designed for precise and efficient labeling of a wide range of square, flat, and rectangular products such as bottles, jars, cartons, cans, and shower gels. Capable of labeling up to 8 products per minute depending on the format, our semi-automatic flat surface labeler stands out for its user-friendly operation and excellent value for money. The Flat Ninette is applicable across various industries, including food and beverage, cosmetics, chemicals, paint, and more.

Request for a quote

CDA

France

The CDA Regionale stands out as a dedicated linear automatic labelling machine meticulously crafted for the wine industry. Its precision is assured by a timing system, ensuring swift and accurate labelling with a capacity of up to 1500 bottles per hour. Designed for the unique requirements of the wine sector, this automatic linear adhesive labelling machine is adept at applying up to four labels (main label, counter-label, neck label, and medal) to wine bottles. Additionally, it facilitates the crimping of both metal and PVC capsules. The Regionale is acclaimed for its user-friendly operation and its seamless adaptability to various wine bottle formats, including half-bottles, 75 cl bottles, magnums, and more. Its effortless integration into both existing and future bottling lines makes it an ideal choice for wineries.

Request for a quote

CDA

France

The CDA R1000/R1500 Mixed Range offers an automatic adhesive labelling solution designed to accommodate both still and sparkling wine bottles, including champagne and sparkling wine, on a single machine. This automatic linear labeller showcases the capability to apply up to four labels (main label, back label, medal, neck label), along with the crimping of aluminum/tin and heat-shrinkable capsules, as well as foils. Renowned for its versatility, this linear automatic labelling machine is a perfect match for various types of still wine bottles (Bordeaux, Côte de Bourgogne, Alsace, Côte du Rhône, etc.), as well as diverse Champagne and sparkling wine bottles (Champagne, sparkling, cremant, etc.), spanning a range of volumes (25 cl, 37.5 cl, 50 cl, 75 cl, magnum, etc.). Switching between bottle sizes (from 1/2 to magnum) is seamlessly achieved without requiring additional equipment.

Request for a quote

CDA

France

The CDA R1000 Foils stands out as an automatic linear labelling machine meticulously crafted for Champagne bottles and sparkling wines. This automatic linear adhesive labelling machine excels at applying up to four labels (main label, back label, medal, and neck label) on Champagne bottles and sparkling wines, along with the added capability of crimping foils. Capable of labelling and crimping up to 800 bottles per hour, the R1000 Foils earns praise for its precision in labelling, user-friendly operation, and swift adaptability. This automatic linear labelling machine is ideally suited for bottles of various types (Champagne, CAVA, sparkling wine, etc.) and volumes (37.5 cl – 75 cl – Magnum – etc.). Effortless integration into both future and existing bottling lines further enhances the appeal of this versatile labelling machine.

Request for a quote

CDA

France

CDA's R1000/R1500 series encompasses automatic linear labelling machines specifically tailored for the wine industry. These machines are equipped to affix up to four labels—main label, back label, medal, and neck label—onto wine bottles, providing the added functionality of crimping metal or PVC capsules. With a commendable level of labelling precision across wine bottle sizes, the R1000/R1500 labelling machines boast a labeling capacity of up to 1500 bottles per hour. Setting themselves apart with user-friendly features, these machines in the R1000/R1500 series demonstrate seamless adaptability to diverse bottle formats (25 cl, 37.5 cl half bottle, 75 cl bottle, magnum, etc.) without the need for additional equipment. An automatic linear labeller from the CDA R1000/R1500 series can be effortlessly integrated into a comprehensive bottling line.

Request for a quote

CDA

France

The CDA Stick stands out as a flexible standalone machine designed for the precise application of adhesive labels onto diverse containers such as cartons, boxes, cans, rectangular bottles, buckets, and BIBs. For seamless integration into existing conveyor systems, the labelling head of the Stick is adaptable and can be easily incorporated using an adjustable support. This support ensures convenient adjustments in both height and depth through a crank handle. Moreover, the Stick provides the option of mounting on a height-adjustable stainless steel frame, enhancing its adaptability. You can configure the machine with one or two labelling heads based on your specific requirements. To enhance its versatility, the Stick offers a swivel head for top labeling applications. Its user-friendly control system features a touch screen interface, ensuring effortless operation.

Request for a quote

CDA

France

The CDA Ninette Auto stands as an ultra-compact semi-automatic adhesive labeling machine designed for applying up to two labels on various cylindrical products, including bottles, vials, jars, buckets, and more. Featuring a production rate of up to 600 products per hour, this semi-automatic labeler is controlled through an intuitive touch screen. Ideal for very small businesses and SMEs seeking a labeling solution for their modest productions, the Ninette Auto is versatile and adaptable to a wide range of cylindrical products in diverse sectors. These sectors include viticulture (wine bottles: half-bottles 37.5 cl, bottles 75 cl, magnum, etc.), cosmetics (cream, perfume, liquid soap, etc.), food (fruit juices, condiments, honey, jam, sauce, etc.), chemistry (household products, maintenance products, motor oil, detergent, solvent, etc.), and paint and varnish (pots, cans, etc.).

Request for a quote

CDA

France

The CDA Ninette 2 stands out as an efficient semi-automatic labeling machine designed to apply two adhesive labels simultaneously on cylindrical products. Boasting an impressive speed of up to 600 bottles per hour, the Ninette 2 is a versatile solution suitable for a diverse range of industries. Whether you operate in the wine and spirits sector, brewing industry, food and beverage production, or cosmetics, this labeller excels at handling various product formats, including wine bottles, beer bottles, cans, jars, pots, and more. A notable advantage of the Ninette 2 lies in its exceptional versatility. It accommodates products of different compositions, such as glass, PET, and PVC, without necessitating material changes. This flexibility ensures a smooth integration into your existing production line, streamlining your operations. The Ninette 2 addresses the needs of small businesses and SMEs seeking a labelling solution for their small-scale productions.

Request for a quote

CDA

France

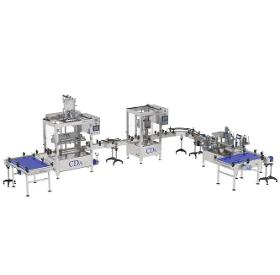

The complete line for small products integrates three crucial phases of packaging: filling, screwing, and labeling. Ideal for small-scale productions with outputs reaching up to 15 products per minute (900 products per hour), this configuration caters to cylindrical products within the 5ml to 250ml range. Suited for various industries, including pharmaceuticals, cosmetics, food, and e-liquids, this comprehensive line ensures efficiency and versatility.

Request for a quote

CDA

France

In our lineup of equipment, the K-Line S takes the spotlight as an enclosed linear filler, celebrated for its user-friendly interface and easy adjustability. Renowned for its exceptional versatility, this machine is highly regarded for its efficient cleanability. With the K-Line S, achieving a filling capacity of up to 3,000 liters per hour is possible while maintaining an accuracy of +/- 0.5% of the dosed volume. Integrated into the production flow using a linear conveyor (or a curved/U-shaped design, depending on your workshop layout), the VS2000 capping machine effortlessly handles the automatic feeding and capping of a diverse range of closures. The final phase of the packaging line is seamlessly executed by the Ninon Mix labeller, which can also be configured for cartoning upon request. The Ninon Mix stands out for its impressive versatility, capable of applying up to 5 self-adhesive labels.

Request for a quote

CDA

France

The K-Line S stands out as an enclosed linear filling machine, appreciated not only for its user-friendly nature and self-cleaning capabilities but also for its remarkable versatility. Tailored to the specific characteristics of your products, we employ the appropriate dosing system—be it volumetric, flowmetric, centrifugal dosing, among others. Remarkably, the K-Line S achieves a filling capacity of up to 3,000 liters per hour while maintaining a high level of accuracy at +/- 0.5%. Complementing this, the VS1000 capper, seamlessly integrated with a linear conveyor (or curved to suit your workshop layout), is also fully enclosed. This capping powerhouse accommodates an extensive range of caps, leveraging an electric screwdriver-operated capping system ideal for various cap types, including gun caps, spray caps, dropper caps, and more. To complete the packaging line, the Ninon Mix labelling machine takes center stage.

Request for a quoteResults for

Labelling machine scales - Import exportNumber of results

71 ProductsCountries

Company type