- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- lightweight concrete

Results for

Lightweight concrete - Import export

ARTRA LIGHTWEIGHT CONCRETE TECHNOLOGIES

Turkey

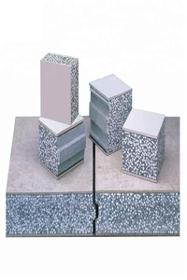

Lightweight Concrete Building Elements ARTRA® CLC Wall Panels Cellular Lightweight Concrete Wall System Cellular Lightweight Concrete is one of the construction materials. less weight has than normal conventional concrete. It can speed up the construction time, easy to install, and is durable. It also has good thermal insulation property, good sound absorption, good fire resistance, and considered as environment-friendly sustainable material produced with the least energy demand. This wall system used for both indoor and outdoor. The surface has been smooth and patching requires only at joint areas. Cellular Lightweight Concrete Wall system consists of the following main parts components; Cement, sand, water and organic foam agent. For example, the CLC Panel size is 250 x 600 x 2700 mm. Weight 64kg / panel The size of the galvanized steel frame is 0.50 x 50 x 35 mm.

Request for a quote

ARTRA LIGHTWEIGHT CONCRETE TECHNOLOGIES

Turkey

POLIFIL: E.P.S Styrofoam granular mortar - concrete admixture It forms a bond between styrofoam granules and cement mortar. It creates air bubbles in the cement mortar accumulated in the gap between the granules and reduces the cement consumption. It provides good strength due to the crystallization in the inner wall of the cement mortar surrounding the air bubbles surface. Prepared with POLİFİL, Styrofoam Granulated concrete Breathable, Does not perspiration, Moisture-proof. It provides long-lasting concrete. Styrofoam Granulated Concrete Concrete Surface No dusting. Concrete, Concrete surface becomes hard and Strength. Styrofoam does not to the surface. There is no need to cover the screed surface with concrete. Ceramic, Tiles, Stone, Parquet Can be easily bonded. Styrofoam Concrete does not collapse under Heavy Load.

Request for a quote

ARTRA LIGHTWEIGHT CONCRETE TECHNOLOGIES

Turkey

GENFİL (Foam Agent) It is a high efficient, organic resin-based foam agent developed for the production of lightweight concrete and lightweight structural elements in the construction sector. The foam material is composed of antibacterial, enzyme-based, active proteins. It is organic, does not harm nature, is not harmful to human health.

Request for a quote

ARTRA LIGHTWEIGHT CONCRETE TECHNOLOGIES

Turkey

In buildings, interior and exterior facades are used. Makes heat insulation. Makes sound insulation. It does not contain water and moisture. New generation wall systems.

Request for a quote

FLEXI LITE CRETE STEEL AND TIMBER FRAME CLADDING BOARD

Turkey

Advantages of EPS Cement Board 1. Lightweight: 350 - 550kg/m³ 2. ECO-friendly: Energy saving, non-toxic, asbestos free. 3. Fast&Quick installation: 2 workers install 150 m2/day(8h) 4. Labor cost saving: fewer workers, and build more fast. 5. Thermal Insulation: Summer cool, Winter warm inside of building, 6. Fire proof: A1 class , 120 minutes 7. Anti-seismic: earthquake resistance can reach to 8 magnitudes. 8. Long life-span: More than 70 years. 9. Water-proof: no drop down stand alone. 10. Voice: Perfect Acoustic insulation and absorption. 11. Transport: High capacity truck&container loading 600 x 1800 x 30mm: 1600 m2 // 60mm: 800m2 // 90mm: 550m2

Request for a quote

MODSTEEL PREFABRICATED MODULAR STEEL STRUCTURES

Turkey

MODSTEEL Ready-made wall panels are a newly invented wall block technique that is easy to use when building prefabricated homes as well as conducting interior space re-shaping in homes or workplaces. It can also be used in sheathing building walls in a safe and almost effortless manner. Our ready-made wall panels do not require lots of workmanship as it can be easily customized and cut into different shapes and sizes. Specifications The main components of the ready-made walls are gypsum board frames from each side that is then filled with expended polystyrene (EPS) a material that increases the insulation level of the wall. We also use a light cemented foam filling instead of traditional concrete in order to have better heat and sound insulation. The walls are totally fire proof even when exposed to direct fire which makes them a very safe choice for homes and places that include children, elderly and valuable material every panel weighs 350kg/m3.

Request for a quote

MODULE-T

Turkey

The cost of construction is much lower than a traditional concrete construction. Assembly is quick. You can erect your prefabricated studiostyle home in a few hours. Maintenance costs are low. The civil engineering costs for the construction are low. It is installed on lightweight concrete (concrete slab or plinth). The prefabricated home structure has an average lifespan of 60 years. The design is performed according to the architectural requirements requested. Our interior architects can assist you with the many options we can offer for your home (custom kitchen, various bathroom options, etc.) Fully insulated house that meets your thermal and sound insulation requirements. Prefabricated construction complying with antiseismic standards. Tailored construction complying with anticyclonic standards, particularly those applicable in the Caribbean countries. Technical assistance with the help of a supervisor or an assembly team to see to the installation of your project.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Standard equipmentwith tilting alu sliding table 1000x800 mm Cutting height 424 mm Cutting length 700 mm Roller diameter 500 mm Saw band length 3720 mm a) for three-phase current 400 V, 50 Hz, motor power 1,3 KW b) or alternating 230 V, 50 Hz, motor power 1,3 KW only saw band, to be selected according to the type of stone material with jack rings and 2 rollers Sound emission Lpa according to DIN 45635, part 1651 on gas concrete and lightweight refractory bricks ...75 dB(A) on Poroton ...................................... 88 dB(A) Size LxWxH: 1000x1000x1800 mm Weight: 130 kg

Request for a quote

ABS SAFETY GMBH

Germany

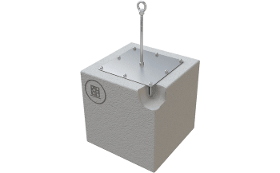

Particularly robust stainless steel anchorage point with a screw-on supporting tube (Ø 42 mm), base plate (200 x 200 mm) and counter plate (100 x 100 mm). This anchor can be installed in a ceiling, on a facade, on a hollow profile or in lightweight concrete to secure 3 individuals. It can also be implemented as a trouble-free end support in a lifeline system. EN 795:2012, A + CEN/TS 16415:2013 Suitable for installation in a ceiling, on a hollow profile or in lightweight concrete Incl. stainless steel installation set Optional: Installation aid ABS-Lock X-DURCH Sleeve

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16 mm) was specially developed with a larger base plate (370 x 370 mm) for installation in lightweight or porous concrete. The 8 anchor rods supplied in the package are cemented permanently into the concrete substructure using special adhesive. EN 795:2012, A + CEN/TS 16415:2013 Porous concrete ≥ P3.3 Add a supporting tube for usage as an end or corner post in a lifeline system Recommended accessories: Special Adhesive WIT-VM-250 Incl. stainless steel installation set

Request for a quote

ARNTZ GMBH + CO. KG

Germany

The universal band saw blade for all construction and insulation materials of small and large dimensions running on brick band saw machines. The new variable tooth pitch ensures notably low-vibration and quiet sawing processes and assures supreme quietness. The results are clean and smooth cuts of the best quality. Thanks to its long blade life and increased durability, our further developed, precision-ground tooth geometry is particularly convincing in hard building materials: • particularly low vibration and quiet • long blade life in especially precise and smooth cuts The specialist for: • Pore or lightweight concrete • Perforated brick • Porous bricks ("Poroton") • Insulation material

Request for a quote

LASPARSAN COMPANY

Turkey

"The LPS-DSC-200 is tailored for use in lightweight concrete spraying jobs, representing an essential addition to your machinery fleet due to its low purchase and operating costs, as well as practical usability. Thanks to its rotor structure that accommodates all commonly used shotcrete concrete, the machine can spray aggregates up to 20mm in size, including gravel, crushed stone, and coarse sand. This machine is ideal for a wide range of applications in shotcrete work, offering practicality and cost-effectiveness in your operations."

Request for a quote

LASPARSAN COMPANY

Turkey

The LPS-DSC-100 is designed for use in lightweight concrete spraying jobs, offering low initial and operating costs along with practical usability, making it an indispensable addition to your machinery fleet. Its rotor structure is capable of handling all types of commonly used shotcrete concrete, allowing the spraying of aggregates up to 12mm in size, including gravel, crushed stone, and coarse sand. The machine is suitable for a wide range of applications in shotcrete work, providing practical usage and cost-effectiveness in your operations."

Request for a quote

LASPARSAN COMPANY

Turkey

The LPS-ASM-100 is an essential machine in your equipment fleet designed specifically for lightweight concrete spraying jobs, boasting a fully pneumatic system. It offers low acquisition and operational costs along with practical usage. With its ergonomic and economic advantages in both infrastructure and superstructure construction, it stands as one of the most preferred machines in the rapidly evolving industry. Particularly in mining structures, it eliminates potential risks of fire and explosions resulting from gas compression using its pneumatic system. Its compact design enables operation in low-ceiling enclosed spaces and narrow areas.

Request for a quote

LASPARSAN COMPANY

Turkey

"The LPS-RSM-500 is a concrete and refractory spraying machine designed for lightweight and precise coating applications, offering low operational costs. With various motor models available, the machine has the capability to spray lightweight shotcrete concretes, refractory concretes, or mixtures prepared for different purposes with aggregate sizes smaller than 12mm. Its enhanced rotor geometry, high-strength steel plates, and meticulously crafted surface plates made of natural rubber ensure dust-free operation, leading to savings in raw materials, labor, electricity, and air. The rotor lubrication system prevents wear on rubber and steel surfaces. Electrical safety is ensured with a waterproof electrical panel. The machine is equipped with a waterproof electrical panel for electrical safety."

Request for a quote

EAB ASSOCIATES

United Kingdom

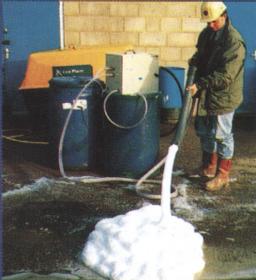

The EABASSOC Foam Generator creates foam from EABASSOC Foaming Agent (or similar), water and compressed air. The foam can then be used for making foamed concrete (also known as cellular lightweight concrete, CLC or aircrete). Specifications: *Throughput of foam 460 litres per minute *Accurate Foaming Agent dosing *Total Repeatability *Adjustable Injection Rate *Mobile (fits in car boot) *Compact - measures only 610 x 450 x 280 mm *Light enough to be easily carried - 24 kg *Requires only an air supply to work, no electrical supply needed *On/Off Timer Switch *Lance for discharging foam into ready mix truck mixer

Request for a quote

EAB ASSOCIATES

United Kingdom

EABASSOC Foaming Agent is a concentrated foaming agent with low dosage rate of 0. 3 - 1.0 litre per m3 of foamed concrete, depending upon the density of the foamed concrete and mineral content of water used to dilute the foaming agent. An EABASSOC Foam Generator (or similar) is required to produce the foam. Foamed concrete, also known as cellular lightweight concrete (CLC) can be made with a density of 400 - 1600 kg/3 and compressive strength of 1 - 15 MPa. Foamed concrete can be used for many applications, such as: * pre-cast blocks and panels * in-situ panels * roof insulation * floor screeds and raising floor levels * planned and emergency void filling * road sub-bases * bridge repair, strengthening and abutments * trench reinstatement * soil stabilisation * land reclamation For more information please contact us.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ARTRA LIGHTWEIGHT CONCRETE TECHNOLOGIES

Turkey

Capacity: 100 LT/ minu. Dimensions: 110X70X80 (u.g.y) Weight Total: 70 kg Tank Capacity: 50 lt System: Air compressor foam nozzle and chassis Total power: 2 KW Energi: 220 W Control: Manuel

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

with expanded clay or with mineral wood fibres The factors that mostly affect the efficiency of acoustic barriers are sound-insulation linked to the masses involved and sound-absorption linked to the porosity and shape of the materials. The noise barrier consists of two layers, one of normal reinforced concrete with a density of 2200-2400 kg/mc, having a supporting function, one of light porous concrete with a density of 900-1100kg/mc. FIP and TECNOACUSTICA offer a noise barrier consisting of a 100mm-thick prefabricated structure of self-stable reinforced concrete and a Greek-fretted facade made of lightweight concrete panels with expanded clay and/or mineral wood fibres for a total thickness of 120mm. The standard length of panels is 292 cm, which permits a typical centre distance of 3 metres. In terms of height, standard measurements of individual panels are 1.5 metres and 2 metres. Panels are fitted onto metal frames that are dimensioned so as to withstand the stress resulting fro

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

Another type of noise barrier solution is the use of typical building materials like concrete. Noise barriers TYPES: 6W64 TECNOWALL green wall TECNOWALL sound-absorbing concrete and lightweight concrete panel expanded clay or mineral wood fibres.

Request for a quote

PASCHAL-WERK G. MAIER GMBH

Germany

The shoring frames TG 60 are made of steel tube of higher strength and are stiffened with 2 small diagonal braces. To transfer tensile forces, every frame is secured by hinged pins, locking pins or bolts to each other. In this way the towers can be assembled on the ground and placed by a crane. The shoring frames TG 60 are designed symmetrically – because of that you don’t have to care about the direction of the diagonal braces.

Request for a quote

PASCHAL-WERK G. MAIER GMBH

Germany

LOGO.alu formwork is light and can be moved by hand, while possessing virtually all characteristics of a large area system. It is suitable for use on building sites where no crane is available.

Request for a quote

PASCHAL-WERK G. MAIER GMBH

Germany

Due to the low weight (30 kg/m²), the NeoR can be moved easily by hand – ideal for construction sites, even without a crane. - Universal fields of application: Foundations, columns, beams, walls - Height offset of the panels can be performed via oblong holes in the panel frame - Well-balanced range of panels - Keybolts as lightweight, friction-locked and cost-effective connecting pieces - Easy attachment of accessories using the hook head principle - The structural height is just 7.5 cm → low storage and transport volume - The flat steel frame guarantees robustness and durability - Fresh concrete pressure capacity of 50 kN/m² - Compatible with all PASCHAL systems Technical Data Panel widths: 90/75/60/45/30/15 cm Panel heights: 150/90 cm Large-size panel: 180 x 300 cm Frame depth: 7,5 cm Plywood: 12 mm birch plywood Max. concrete pressure: 50 kN/m² according DIN 18218 Tolerances of deflection: According DIN 18202, table 3, line 6

Request for a quoteResults for

Lightweight concrete - Import exportNumber of results

24 ProductsCountries

Company type

Category

- Formwork contractors (3)

- Concrete mixers (2)

- Concrete preparing - machinery and equipment (2)

- Insulating panels, asbestos-free (2)

- Acoustic panels (1)

- Building materials (1)

- Concrete constructions (1)

- Concrete, ready-mixed (1)

- Construction Materials (1)

- Construction machinery (1)

- Hand tools, non-power (1)

- Lightweight metal scaffolding (1)

- Mortars and cements, refractory (1)

- Natural resins (1)

- Prefabricated houses (1)

- Sawing machine tools (1)

- Tools, pneumatic (1)