- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnetic filters

Results for

Magnetic filters - Import export

IDEMAG

Spain

ThisÊmagneticÊsystemÊisÊspeciallyÊdesignedÊforÊtheÊ extractionÊofÊferromagneticÊparticlesÊinÊtheÊflowÊofÊ materialÊthatÊcirculatesÊthroughÊaÊpipe,ÊhopperÊorÊsi- milar,ÊforÊtheÊprotectionÊofÊequipment,ÊthusÊavoidingÊ unnecessaryÊdamageÊsuchÊasÊstoppagesÊforÊrepairsÊ andÊimprovingÊtheÊqualityÊofÊtheÊrawÊmaterial. ThisÊsystemÊcontains,Êinside,ÊaÊmagneticÊcircuit,ÊbuiltÊ withÊmagnetsÊwhichÊcreatesÊaÊpermanentÊmagneticÊ field. WhenÊtheÊmagneticÊgridÊisÊfullÊofÊmetalÊparticles,ÊitÊisÊ necessaryÊtoÊseparateÊthemÊusingÊtheÊmanualÊ cleaningÊsystem.

Request for a quote

STRONG MAGNETS GMBH

Germany

Scope of application Magnetic filter rod (magnetic rod) is mainly used to remove ferromagnetic impurities in powder, granular and liquid or slurry. It is widely used in ceramics, power, mining, plastics, chemical industry, rubber, pharmaceuticals, food, environmental protection, pigments, dyes, electronics, metallurgy and other industries. Working Principle The magnetic rod is made of high quality stainless steel pipe and high B value rare earth alloy NdFeB, and is made by special manufacturing method. The magnetic filter can be assembled on a fixed frame to form a magnetic filter. When the material containing iron passes through, it is attracted by the magnetic rod, and the material containing iron is firmly adsorbed on the wall of the magnetic rod. To ensure the integrity of equipment and product safety. Product features energyfree, pollutionfree, can be installed in any position on the production line with material contact, saving space, easy installation.

Request for a quote

VIRA ISI

Turkey

Magnetic Deaerator and Dirt Separator are used with a single device to dissolve microbubbles, dirt, and air in high performance in heating and cooling installations. Micro smart filter design is the most important element of the system design. Optimum air and microbubble separation and very low flow resistance are available. It also has a high degree of dirt handling. With its magnetic Separator feature, ViraPlus separates the moving metal particles in the installation more effectively and ensures faster cleaning of the installation. It also extends the life of your pump and other connecting equipment by minimizing the damage caused by metal parts to high-efficiency pumps that provide low energy consumption.

Request for a quote

VIRA ISI

Turkey

The ViraClean is a high-efficiency in-line dirt trap, suitable for use on heating and chilled systems. Corrosion is a process that is difficult, if not impossible, to stop once it has begun. Corroded metal becomes dislodged and becomes water-borne debris. This debris, along with other contaminants in the system, clogs heat exchanger channels, fouls filters, and causes excessive wear in circulating pumps. Effective removal of debris is essential for increasing the operational life of the system as a whole.

Request for a quote

VIRA ISI

Turkey

In heating and air conditioning control systems, the circulation of water containing impurities may result in rapid wear and damage to components such as pumps and control valves. It also causes blockages in the heat exchangers, heating elements, and pipes, resulting in a lower thermal efficiency within the system. The dirt separator separates off these dirt particles, collecting them in a large collection chamber, from which they can be removed even while the system is in operation. This device is capable of efficiently removing even the smallest particles, with extremely limited head loss.

Request for a quote

GOUDSMIT MAGNETICS

Netherlands

Magnetic separators filter ferrous and weakly magnetic metals from your product flow. These contaminants can remain in your end product and cause rejection, but can also damage your process machines. Examples of ferrous metals in your production line: rivets, nails and screws of packaging, loosened bolts and nuts, wear of moving parts, rust or corrosion. We offer you a wide range of magnetic separation systems, that are suitable for removing large loosened parts, up to very fine wear particles. And with manually to fully automatic cleaning systems.

Request for a quote

GOUDSMIT MAGNETICS

Netherlands

Magnetic separators filter ferrous and paramagnetic metals from product flows. These contaminations can remain in your end product and cause rejection, but can also damage your process machines. Examples of ferrous contamination in your production line: rivets, nails and screws of packaging, loosened bolts and nuts, wear of moving parts, rust or corrosion. We offer you a wide range of magnetic separation systems, that are suitable for removing large loosened parts, up to very fine wear particles. And with manually to fully automatic cleaning systems.

Request for a quote

GHM MESSTECHNIK GMBH

Germany

Filter inserts 250 to 600 Media temperature up to 150 C Nominal widths DN 15 to DN 80 Red brass/brass materials

Request for a quoteFAUDI GMBH

Germany

Advantages Parallel alignment of multiple magnetic cartridges enables a large filtration area on limited space Low flow speed guarantees long filter life cycle Area of application For the separation of ferritic impurities out of coolants with low requirements on the purity degree. Flow rate Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid without Filtration degree - Medium oil, emulsion and water Filter material magnetic cartridge

Request for a quote

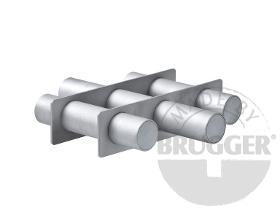

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised sizes

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised sizes

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised sizes

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand. Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised sizes

Request for a quoteFAUDI GMBH

Germany

Advantages Parallel alignment of multiple magnetic separators enables a large flow-rate Extrem durable construction Magnetic rotor up to 1.600 mm width High filtration degree due to optimized design Area of application For the separation of ferritic impurities out of coolants with low requirements on the purity degree, as well as a pre-cleaning step in front of filter systems. Flow rate Various filter sizes and the modular design enable any required flow rate. classification number - Filter aid without Filtration degree - Medium oil and emulsion Filter material magnetic rotor

Request for a quote

TROTEC GMBH

Germany

WATER SEPARATOR WA 4I MULTIQUBEWater separator WA 4i for combination with MultiQube insulation layer dryers The new WA 4i is provided with an integrated micro filter system with low-maintenance magnetic lock filter compartment to take in micro filter cartridges with a threefold filter element. This makes the WA 4i a versatile integral solution with all pre-HEPA filter stages in only one device. Advantage: improved flow-optimized filter technology, quicker setup, decreased material and space requirements – no separate additional micro filter housings required. With respect to insulation drying of surfaces sized up to 40 m², no other model is quite fit to hold a candle to this separator, for despite its ultra-compact dimensions the WA 4i comes fully equipped with numerous practice-oriented detailed solutions, such as a construction yet easier to maintain, TTKwic quick couplings, cable holder, residual water drainage and much more.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center – year of construction: 2007-2008 Product name: MFZ 2-3 Update Used 3-spindle horizontal 4-axis machining center Year of manufacture: 2007-2008 Painted in RAL1002 (sand yellow) or red-white Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (per machine without coolant system and accessories) X-axis travel: 300 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 300 mm Rapid traverse XY Z axis 60,000 mm/min 3 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm Chip conveyor Knoll (scratch belt conveyor in positioning variant across the machine) Knoll KSS system with paper belt filter and magnetic separator Flush gun Complete enclosure Tool storage (3 x 30 tools)

Request for a quote

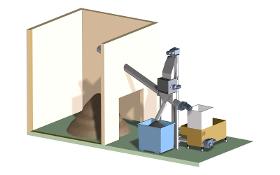

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

The feeding station (hopper) minimizes dust spillage through the blower and filter stand when manually opening and discharging the bag of material into the production line, thus keeping the working environment clean. Vibrator, filter, magnet, vibrating bridge destroyer, material suction equipment and feeding screw are all optional equipment.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Eclipse’s patented magnetic filtration or magnetic separation systems are the ultimate in filtration technology, providing, quality and environmental benefits. The Filtramag is the ultimate in filtration technology, its’ high intensity magnetic cores make it 1005 effective for use with materials which have lower magnetic permeability such as tungsten carbide and cast iron. With a stainless steel construction it is ideal for use in harsh chemical environments and wash systems. Patented design. Easy installation. Unique dual flow technology™ maximises collection capability. Operates at up to 20 bar. Removes both magnetic and non-magnetic contamination. Minimal pressure drop. In-line connections. Ideal for use in harsh chemical environments. The dual chambered design means that fluid is exposed to the high intensity magnets for the maximum time thus ensuring almost 100% of contamination is removed on first pass through the filter. High intensity magnetic cores ensure particle

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Equipment New triple filtration design: coarse filter, fine filter, magnet Filterbag Usable area 730 x 520 mm with load capacity 100 kg Unit out of plastic (PE), no risk of corrosion. Extra easy to maintain - Control box contains the complete control- and pump device. Can be exchanged fast and easy at malfunction. Drain device make the exchange of the bio cleaner easier.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Equipment New triple filtration design: coarse filter, fine filter, magnet Filterbag Usable area 730 x 520 mm with load capacity 100 kg Unit out of plastic (PE), no risk of corrosion. Extra easy to maintain - Control box contains the complete control- and pump device. Can be exchanged fast and easy at malfunction. Drain device make the exchange of the bio cleaner easier.

Request for a quote

GP-MAGNETS

United States

Neodymium Arc Magnet Is An Important Part Of Electric Motors. GP Magnets provides powerful, long lasting and inexpensive arc neodymium magnets for your motors and magnetic assemblies. Material: NdFeB, rare earth NdFeB arc magnets Technology: a new type of sintered NdFeB magnets Process and equipment, such as band casting, HDDR technology. Magnetic properties: A. High coercivity B. (BH)max from 33 to 53 MGOe. C. Maximum operating temperatures up to 230°C. Grades: N33-N52, 33M-48M, 33H-48H, 30SH-45SH, 30UH-38UH, 30EH-35EH Shape: Arc, Tiles, Segment, Disc, Cylinder, Ring, Square, Block, Rod, Cube, Trapezoid and Customized shapes Size: 3mm, 5mm, other sizes can be customized Coating: NI, NICUNI, Zn, NiCU-Gold, copper, Epoxy, NICU-Epoxy, chemical, propylene, etc. Applications: Sensors,motors,filter automobiles,magnetics holders,loudspeakers,wind generators, medical equipments, etc.

Request for a quote

GP-MAGNETS

United States

Neodymium Arc Magnet Is An Important Part Of Electric Motors. GP Magnets provides powerful, long lasting and inexpensive arc neodymium magnets for your motors and magnetic assemblies. Material: NdFeB, rare earth NdFeB arc magnets Technology: a new type of sintered NdFeB magnets Process and equipment, such as band casting, HDDR technology. Magnetic properties: A. High coercivity B. (BH)max from 33 to 53 MGOe. C. Maximum operating temperatures up to 230°C. Grades: N33-N52, 33M-48M, 33H-48H, 30SH-45SH, 30UH-38UH, 30EH-35EH Shape: block, cube, ring or other Size: L x W x H, mm/in. Custom; Max. block length 150mm, max. ring D220mm, min. thickness 0.5mm Max. block length 150mm, max. ring D220mm, min. thickness 0.5mm Coating: NI, NICUNI, Zn, NiCU-Gold, copper, Epoxy, NICU-Epoxy, chemical, propylene, etc. Applications: sensors, motors, rotors, wind turbines/wind turbines, speakers, hooks, magnetic holders, filters, automobiles, etc.

Request for a quote

STEINER GMBH & CO. KG

Germany

Impurities of your transported goods are often problematic and can be also guilty of disorders. They may even cause damage. But do not desperate! Our tried and tested magnetic separators will help you. These magnetic separators take care to filter out foreign substances. Simply and reliably.

Request for a quote

MAKOHATECH

Turkey

sondex serii ,mold manufactor plate heat exchanger

Request for a quote

BLUE KLIMA

Turkey

Plate heat exchangers consist of a number of corrugated plates. The plate pack is mounted between a fixed and movable pressure plate, positioned by an upper and lower carrying bar, and compressed by several tightening bolts. The media involved in the heat exchange process are fed into the plate pack via connections on the fixed and movable pressure plates. The arrangement of the plates creates two separate channel systems, enabling the two media to flow past and between each other without physical contact, leaving the exchanger again via connections in the pressure plates. Plate with different patterns can be mixed in the heat exchanger in order to achieve optimum efficiency at a given pressure drop.

Request for a quoteResults for

Magnetic filters - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Magnets (10)

- Magnetic equipment (3)

- Central heating systems (2)

- Metal detectors (2)

- Screen filters (2)

- Boilers, domestic (1)

- Chemical industry - machinery and equipment (1)

- Expanded metal plates (1)

- Filtering equipment and supplies (1)

- Foods, precooked and gourmet (1)

- Heat exchangers (1)

- Mechanical engineering - custom work (1)

- Tumble dryers and spin dryers, industrial (1)