- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnetic powder

Results for

Magnetic powder - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

The characteristics of Samarium Cobalt Magnet •Very high magnetic properties with good stability •High magnetic performance - up to about 32MGOe •Superior resistance to high temperature, Curie temperature of majority is over 800°C •Excellent corrosion resistance capability, no coating is needed for surface protection

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

YX series Alnico Magnetic Powder, bonded alnico powders are suitable for making various bonded alnico magnets. They have good compatibility with different kinds of composite size, such powders have high filling capacity. The strict quality control system of our plant ensures that the quality is stable and consistent. Applications •Alnico Powder for sintered Magnets. •Alnico Powder for Bonded Magnets. •Purity convergence Magnet. •Beam Arrangement Magnet. •Magnetic bearings and braking magnet in watt-hour meters. •Telephone receivers. •Small sized motors for special purposes.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Strontium Dry Pressing Ferrite Magnetic compound are suitable for producing magnets by dry pressing. Strontium ferrite material features better magnetic property than barium ferrite material in the area of remanence induction intensity, coercivity and magnetic hysteresis loss. Strontium compound have been added proper quantity of binders and lubricants and pass through 120 mesh sieve,so as binders to be uniformly distributed for better orientation. We could supply the compound in both spray dried or vibration granulated form.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

There are 6 types of dry pressing ferrite powder for customers: YXC-C1, YXC-C2T, YXC-C3T, YXC-C1, YXC-C2. The procedure summaries for making magnet are as follows: •The necessary secondary additives have been added into the powder during the grinding process. Customers only need to add proper quantity of binders and lubricants. The powder must pass through 120 mesh sieve before pressing, so as binders to be uniformly distributed for better orientaton •Please take care of the cleaning of the equipments. Any other materials and impurity should mot be mixed into the powder •During pressing, the pressure required is ≥5000N/cm2, and the magnetic field density is >7000 Oe(560KA/m) •The sintering temperature for reference is between 1220 °C and 1270 °C. Please note that the proper sintering temperature should be defined in accordance with the status of the sintered sample pill

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

YX Wet Pressing Strontium Ferrite Magnetic Powder Specifications YX series wet pressing strontium ferrite magnetic powders have been designed to produce all grades of hard ferrites. The users can produce high quality magnets by adding the provided additives into the powders. Our highly automatic instruments and strict quality control system ensure that the quality is stable and reliable

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

CHARACTERISTICS •Design and manufacturing of orientation moulds were carried out •Having high dimensional precision and impact-resistance •Capable of forming products with inlay •The injection moulding parts are suitable for forming products with various shapes and thin walls •Multi polar magnetization can be carried out as per customer's requirements APPLICATIONS •Different kind of micro-special motor •Different kind of fan motor •Different kind of DC motor •Synchronization electric motor •House electric apparatus •Ice chipper electric motor •Hand-operated electric generator •Automobile motor •Time gauge •Instruments for auto

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

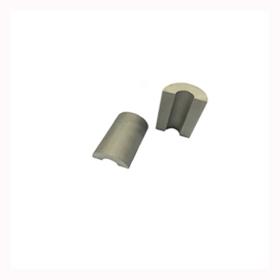

Features: Made of ground sintered SmCo magnet Powder is mixed with resin and molded like NdFeB bonded magnet No need to be coated because it is difficult to erode and oxidize High-BH (maximum) High-Br and Hc with high-operating temperature, low-temperature coefficient, counter-demagnetization, decay resistance Main products cover SmCo5 and Sm2Co17 magnets, samarium cobalt powder, various assemblies and more OEM orders are welcomed Applications: Widely used in motors, watches, transducers, instruments, positional detectors, generators, radars and more High quality, competitive price, best service

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Features: Made of ground sintered SmCo magnet Powder is mixed with resin and molded like NdFeB bonded magnet No need to be coated because it is difficult to erode and oxidize High-BH (maximum) High-Br and Hc with high-operating temperature, low-temperature coefficient, counter-demagnetization and decay resistance Main products cover SmCo5 and Sm2Co17 magnets, samarium cobalt powder, various assemblies and more OEM orders are welcome Applications: Widely used in motors, watches, transducers, instruments, positional detectors, generators, radars and more

Request for a quote

N&H TECHNOLOGY GMBH

Germany

Powder technology has a long history in various sectors such as the chemical, food, pharmaceutical and metal industries. Measuring the physical properties of powder is very difficult and each industry uses different assessment methods. The PD-600 powder measuring system is the further development of the PD-51. It can determine the physical properties of powder via resistivity. Powder materials of carbon products: Materials used for rechargeable battery electrodes, condensers and resistance material and insulating electronics / cokes / graphite / carbon black / carbon fiber / nano carbon, etc. Metal powder: Materials used for battery electrodes, thin film materials such as copper powder or ITO powder, for circuit board materials, for example conductive paste and electro conductive paint. Others: Thermoplastic powder, Printer toner, Magnetic material such as ferrite, food material, pharmaceutical related and automobile parts.

Request for a quote

MAGTROL

Switzerland

DESCRIPTION The Torque Powder Brakes (TPBSeries) are ideal for applications operating in the low speed range or middle to-high torque range. These magnetic powder brakes provide full torque at zero speed and are convection or air cooled, allowing power ratings up to 900W (2100W with air cooling). APPLICATIONS These units are suited for tension control applications, such as wire winding, foil, film, and tape tension control. Mounted on test benches, TPB Series - Torque Powder Brakes allow performance and reliability testing on driving elements such as electric motors, hand-held power tools, geared motors, reduction gears, and hydraulic transmission systems. Other applications include load simulation for life testing on electric motors, actuators, gearboxes, power steering, and many other rotating devices and assemblies.

Request for a quote

STRONG MAGNETS GMBH

Germany

Magnetic separator is one of the most widely used and versatile machines in the industry. It is used to remove iron powder from the reused powder granules. Magnetic separators are widely used in resource recovery, wood industry, mining, kiln industry, chemistry, food and other workshops. The magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with particle size less than 3mm. It is also used for iron removal of coal, nonmetallic ore, building materials and other materials. The magnetic system of the magnetic separator is made of high quality ferrite material or rare earth magnets. The average magnetic induction intensity of the barrel surface is 100600 mT.

Request for a quote

FLEXIBLE MAGNET (CHINA) CO., LTD.

Hong Kong

Flexible Magnet is made by high quality ferrite magnet powder and thermoplastics, This product is lead from using strontium ferrite. It do not contain any heavy metal or hazardous chemicals. This type of magnet has the best flexibility characteristics of any permanent magnetic materials. It can be easily folded and twisted without damaging the magnetic property of the magnet. It also has excellent machanibility and can be easily drilled, punched, scissor cut, knift cut and die cut. Dimension: Material is available in Isotropic and Anisotropic grade Material is available in cut sheets and rolls We can die cut the material to any shapes or sizes according to your requirement Length Width Thickness Isotropic Roll Srandard 15M/30M/60M 620MM/1000MM 0.4MM/0.5MM/0.75M Max. 500M 1200MM 0.3MM-3MM sheet Srandard 500MM/1000MM 620MM/1000MM 0.4MM/0.5MM/0.75M Anisotropic Roll Srandard 10MM/15MM 620MM/1000MM 1.0MM/1.5MM/2.0M sheet Srandard 10MM/15MM 620MM/1000MM 1.0MM/1.5MM/2.0M Customized dimensions are also available upon request Magnetic Property: MAGNETIC ENERGY REMANENCE COERFIVE FORCE INTRINSIC COERCIVE FORCE (BH)MAX BR HCB HCJ MGOE KJ/M3 KGS MT KOE KA/M KOE KA/M ISOTOPIC 0.45-0.72 4.0-6.0 1.5-1.8 150-180 1.2-1.5 95-115 1.9-2.1 150-159 ANISOTROPIC 1.2-1.7 10.1-13 2.2-2.6 220-260 2.0-2.3 170-180 2.4-3.5 190-280 Physical Properties: Working temperature: -15 o to 160 oF (-26o-70o C) Hardness: Shore D40 Multi-pole spacing: 12.7 poles per inch Flexibility: At 68 oF, can be coiled to a 1/2” (12.7mm) radius without cracking. Application: Fridge Magnet Magnetic Car Sign Shelf/File Labels Signage Manu Boards Stationary Educational aids Games/Toys Business Card And many more…

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Stainless steel powder 410L is a magnetic grade of stainless steel exhibiting fair corrosion resistance and decent high temperature sintering response as well as good green strength and high compressibility. 410 Steel powder is a magnetic grade of stainless steel. An excellent candidate for automotive sensor ring and mirror mount applications, P410L exhibits fair corrosion resistance and a decent high temperature sintering response. Major performance features of this stainless steel include green strength and high compressibility. Carbon Additions: Fractions of graphite can be admixed for increase hardenability in 410 SS powder. Ferritic stainless steel powdered metallurgy (P/M) technology is specified for longer-term performance and reliability. Good atmospheric and saline corrosion resistance, hot oxidation resistance and elevated temperature yield strength, at the most economical costs are key reasons for using 400 series stainless steel

Request for a quoteResults for

Magnetic powder - Import exportNumber of results

14 ProductsCompany type