- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air guns

Results for

Air guns - Import export

ARUBIS

Belgium

In addition to the range of industrial plugs, Plugtite has developed a range of nozzle adaptors to be used during maintenance of hydraulic lines and channels. Resistance to most oils and chemicals Temperature range from -25°C up to 90°C Does not shrink, leak or discolor Resistant to sunlight for greater shelf life Does not split/crack or deteriorate Easy to use. Insert, squeeze, press home and apply air-gun The compressed rubber ensures a tight fit By using the plugtite rubber nozzle adaptor in conjunction with an air gun it prevents splash-back of any oils, chemicals, liquids, or other debris from the channel /tube/pipe whilst cleaning under high pressure, thereby protecting both the user and the environment in and around the equipment from contamination, and, at the same time ensures that all the air pressure is directed into the channel ensuring a stronger pressure for improved performance.

PLUGTITE

Belgium

Our latest tool for use during the maintenance of hydraulic and other industrial equipment. Small (5.8mm - 30.2mm) Large (14mm - 46mm) Resistance to most oils and chemicals Temperature range from -25°C up to 90°C Does not shrink, leak or discolor Resistant to sunlight for greater shelf life Does not split/crack or deteriorate Easy to use. Insert, squeeze, press home and apply air-gun The compressed rubber ensures a tight fit

ADTECH POLYMER ENGINEERING

United Kingdom

Fluoroplastic roll covers eliminate sticky build-up problems with metal and rubber rollers used in hot or cold applications. We offer heat shrinkable FEP and PFA roll covers in 0.5mm thickness, and standard and custom sizes. Our non-stick roller coatings are available for self-application using a simple hot air gun. Alternatively, we can fit the roll covers in our works or at your premises. For more information, visit the adtech.co.uk website or contact us: t: +44 (0)1285 762000 e: sales@adtech.co.uk

Request for a quote

SEIDEL INDUSTRIAL EQUIPMENT CO., LTD.

China

The Semi-Automatic Cleaning Machine is designed for fully automatic robot manufacturing lines. This machine features an automatic opening and closing door. The workpiece to be cleaned from oil, coolant, chips, and other residues is loaded and unloaded by a robot. The cleaning process is semi-automatic. Inside the processing chamber, is placed an air gun as well as a spray gun. The workpiece table can easily be turned by hand to reach all areas of the workpiece. This machine performs soft cleaning by circulating the cleaning fluid in the process tank and rinsing and drying the workpiece. Select from a range of different programs to provide the best cleaning results.

Request for a quote

LVD

Belgium

Our Compact Tower (CT-P) loads, unloads and stores raw materials, skeletons and finished parts for automated production. The CT-P system creates a flexible manufacturing cell able to operate unmanned around the clock for top productivity. A space-saving design enhances optimal material flow for uninterrupted processing of punched parts. Pallet construction is designed for compact set up and convenient forklift manipulation. KEY FEATURES 6 or 10-pallet configuration Pallet construction designed for compact set up and convenient forklift manipulation Intuitive touch screen graphical user interface Spreading magnet, air gun and peeling cylinder sheet separation devices Integrated or retrofitted to specified models Includes autoload interface PRODUCTIVITY-ENHANCING OPTIONS Integrated or retrofitted to specified models MODELS Available for VX, V, M and PX Series punch presses Specifications Available models 2500 x 1250 mm and 3048 x 1524 mm Handles sheet weights up to 100 kg

Request for a quote

SEIDEL INDUSTRIAL EQUIPMENT CO., LTD.

China

The Semi-Automatic Cleaning Machine is designed for fully automatic robot manufacturing lines. This machine features an automatic opening and closing door. The workpiece to be cleaned from oil, coolant, chips, and other residues is loaded and unloaded by a robot. The cleaning process is semi-automatic. Inside the processing chamber, is placed an air gun as well as a spray gun. The workpiece table can easily be turned by hand to reach all areas of the workpiece. This machine performs soft cleaning by circulating the cleaning fluid in the process tank and rinsing and drying the workpiece. Select from a range of different programs to provide the best cleaning results.

Request for a quote

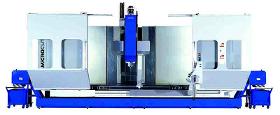

BUFFALO MACHINERY CO., LTD.

Taiwan R.O.C.

TC series is characterized by high speed and superior precision machining. With the design of powerful drivers, moving column and rigid construction, the model is suitable for heavy cuttings with perfect surface roughness. The superior tooling system design features 300mm tool length availability, easy tool loading, servo driver for fast and accuracy tool selection, and extremely large loading capacity. Besides, the machine is equipped well protected guarding for safety. Standard accessories ISO 40 belt spindle(10000rpm) Chip auger CTS system with high pressure 20 bar pump CTS system with high pressure 70 bar pump Water gun Coolant through spindle with high pressure pump Heat exchanger Optional accessories Oil skimmer Safety module Air conditioner Coolant gun Optical scales for 3 axes Automatic door 4th axis preparation (wiring only)

Request for a quote

SIMCO-ION EUROPE

Netherlands

This gun is electrically safe and shockless. The emitter point is coupled capacitively to the high voltage. Thanks to its rugged design this gun is ideal for heavy-duty industrial applications. The airflow is controlled by the trigger. It comes standard with 3 metres of metalshielded cable. One or two guns can be connected to one power unit. Features - Working distance: 300 mm max. - It comes standard with 3 metres cable, 6 or 9 meter is also possible - Ideal for heavy-duty industrial applications

Request for a quote

SIMCO-ION EUROPE

Netherlands

Simco-Ion's Top Gun III is developed for light industrial applications. A high ion production attend to an optimal neutralisation of static charges. High blow-off force and low air consumption provide high-efficiency cleaning. A filter at the exit of the gun ensures that the air is clean. The gun body is lightweight and durable. It features a light-touch trigger, making it comfortable even for extended use. All functionality is built into the gun, including a flowcontrol valve, and a two-level LED which indicates if the gun is in ''stand by'' mode and if high voltage is currently active. Both the gun and cable are static dissipative. A hanger is provided for easy mounting. One gun can be connected to one power unit. Top Gun Side Kick The Top Gun Sidekick offers handsfree operation. A foot pedal controls both ionization and airflow. The Top Gun Side kick includes a flexible mount feature with a bracket for flexible positioning.

Request for a quote

SIMCO-ION EUROPE

Netherlands

The Cobra ionizing air gun is excellently suited for heavy-duty industrial applications. It has a lightweight durable gun body made of highimpact plastic. The airflow is controlled by the trigger. The air flow is amplified by a minimum factor of 6 : 1 by drawing in ambient air through the rear. The high-voltage point integrated aerodynamically in the gun body cleans itself during use. The gun comes standard with 6 metres of cable. Two guns at most can be connected to a single power unit. - Working distance: 600 mm max. - It comes standard with 6 metres cable, 12 metre is also possible - Ideal for heavy-duty industrial applications - The emitter pin is cleaned during use

Request for a quote

SIMCO-ION EUROPE

Netherlands

The Cleanflex Easy ionising air gun can be used for cleaning and neutralising surfaces. It’s unique features, not seen in any other ionising guns, make it very versatile to use. Ergonomic, hand or pull down, less air consumption, low noise, better blow-off force. - 24V DC input voltage and integrated ionisation power unit The Cleanflex Easy has a 24V input voltage, easily connect by a standardised M12 connector. No cumbersome high voltage cable and big transformer unit as seen in traditional ionisation guns. - Lightweight A Durable plastic housing and a well-constructed weight distribution make it a well balanced comfortable gun to use. - Ergonomic design The grip has been designed to suit women’s as well as man’s hands and has a soft grip and grip fixation making it very easy to hold without any muscle tension. - Full hand trigger (no RSI strain on one finger) The air flow is controlled with a full hand trigger, making operation very comfortable.

Request for a quote

ABS SAFETY GMBH

Germany

This shrink tubing is specially designed for anchorage points (Ø 16 mm) and supports that have been reinforced using a supporting tube (Ø 42 mm). It is available in 3 different lengths (300, 600 and 1200 mm) and can be individually shortened. When you heat the tubing up using a hot air gun it shrinks to fit snugly around your sealant collar and anchor. Extension for ABS LockSeal sealant collars Designed for Ø 16 mm posts Available in 3 different lengths: 300, 600 and 1200 mm Simply shorten the tubing to the required length

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Professional Air Operated Grease Gun For 400 gr. Cartridges or 500 gr. Bulk Fill, Filler Nipple/Air Release Valve. Continuous flow with trigger held open. Unique 360 degree swivel head for ease of use. 40:1 Ratio. Air supply recommended.

Request for a quote

PNEUFLEX PNEUMATIC CO., LTD

China

Pneuflex air blow guns (air dust guns, pneumatic blow guns, metal air blow guns, air blower), including metal air blow guns and metal air blow guns, which are often used to clean the dust , water and crumb.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION ACK 420 is designed for the strait or angular cutting operations of the large size of profiles made of PVC and aluminum materials by means of Ø 420 mm of saw blade. HDL 300 It is computerized heavy duty lenghtstop which helps to cut the profiles precisely in the required measurements. ACK 420 General Features Two-hand safety operation Location points at 75°,60°,45°,30°,22.5°,15°,0°, both left and right Pivoting range from -75° left to +75° right infinitely adjustable Hydro-pneumatic saw feed Adjustable back fence for most effective use of the saw blade Adjustable saw blade feeding speed Manually opening safety guard Interior LED lighting STANDARD ACCSSORIES Equipped with saw blade Ø 420 mm Manuel MKN 300 end-stops (3 m) 2 x vertical clamps Spray saw blade lubrication system (ACK 420S) Air gun OPTIONAL ACCESSORIES Laser marker set for 90° of cutting operation Pneumatically working top guard Additional saw blade Ø 420 mm 2x horizontal clamp

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Mold Making Machine; 40" x 26" x 25" (1016 x 660 x 635 mm), 40 taper, 30 hp (22.4 kW) vector drive, 12,000 rpm, inline direct-drive, side-mount tool changer, 710 ipm (18.0 m/min) rapids, automatic chip auger, remote jog handle, automatic air gun, high-speed machining, Ethernet interface, macros, coordinate rotation & scaling, programmable coolant nozzle, power-failure detection module, 1 GB program memory, 15" color LCD monitor, USB port, memory lock keyswitch, rigid tapping and 55-gallon (208 liter) flood coolant system. VM-3 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YILMAZ MACHINE

Turkey

VK 420 is designed for the precise V cutting and 90° end notching operations with minimal off cut size on aluminum and PVC profiles. Machine is constructed to minimize the off cut size Hydro-pneumatic V sawing head infinitely adjustable according to the profile Manual adjustable of back fence working in T slot mechanism Double hand safety operation External adjustment of hydro-pneumatic saw blade feeding 90 degree of notching operation (optional) STANDARD ACCESSORIES • 2 x T.C.T saw blades, Ø 420 mm • 2 x Horizontal pneumatic clamps • Service spanner • Air gun • Spray saw blade lubrication system

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Mold Making Machine; 30" x 20" x 20" (762 x 508 x 508 mm), 40 taper, 30 hp (22.4 kW) vector drive, 12,000 rpm, inline direct-drive, side-mount tool changer, 710 ipm (18.0 m/min) rapids, automatic chip auger, remote jog handle, automatic air gun, high-speed machining, Ethernet interface, macros, coordinate rotation & scaling, programmable coolant nozzle, power-failure detection module, 1 GB program memory, 15" color LCD monitor, USB port, memory lock keyswitch, rigid tapping and 55-gallon (208 liter) flood coolant system. VM-2 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION It is used for the processing of slots for locks, drilling handles, hinges, espagnolette holes and opening water drain slot on PVC and aluminum profiles up to 3 mm of thickness. Opening locks, drilling handles, hinges, espagnolette holes etc. on PVC and aluminum profiles Cast aluminum structure Corrosion proof bearing shaft Robust machine stand constructed from steel sheet Electroplated copy template Two pcs of tracer pins Ø5 router bit included Clamping capacity : W max.:130, W min.:10, H max:130, H min.: 20 mm STANDARD ACCESSORIES • Ø5 mm of router bit • Air gun • 2x left and right profile stops • 2x pneumatic horizontal clamps • Spray tool lubrication system OPTIONAL ACCESSORIES • Additional router bits • Special copy templates • MA 240 centering apparatus • MKN 150 roller conveyor TECHNICAL SPECIFICATIONS 750W 400V 50~60 Hz / 550W 230V 50 Hz x:270 y:110 z:130 mm 14000 D/dak. RPM W:64 L:80 H:149 cm. 110kg. 72 kg.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION It is used for the processing of slots for locks, drilling handles, triple, hinges, espagnolette holes and opening water drain slot on PVC and aluminum profiles Copy fitting operates manually and the figures on the template are machined at 1:1 ratio The aluminum profiles up to 3 mm of wall thickness can be machined with a strong spindle motor The cutting fluid controlled with a joystick is sprayed to the milling spot Slots in varied lengths and widths can be opened without using the copy milling template The length of the water drain slot is adjustable on the template Copy milling motor is directly controlled via joystick Reference stops at 2 sides of the milling machine Standard equipped with inlet-outlet conveyor Ergonomic hand control unit On the horizontal axis there is triple hole drilling mechanism Pneumatically working water slot opening system STANDARD ACCESSORIES Ø 5mmx L :80mm of router bit Air gun 2 x profile stops both left and right

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION It is used for the processing of slots for locks, drilling handles, hinges, espagnolette holes and opening water drain slot on aluminum profiles up to 3 mm of thickness. Copy fitting operates manually and the figures on the template are machined at 1:1 ratio The aluminum profiles up to 3 mm of wall thickness can be machined with a strong spindle motor The cutting fluid controlled with a joystick is sprayed to the milling spot Slots in varied lengths and widths can be opened without using the copy milling template The length of the water drain slot is adjustable on the template Copy milling motor is directly controlled via joystick Reference stops at 2 sides of the milling machine Standard equipped with inlet-outlet conveyor Ergonomic hand control unit STANDARD ACCESSORIES • Ø 5mmx L :80mm of router bit • Air gun • 2 x profile stops both left and right • Spray tool lubrication system • 2x horizontal clamps OPTIONAL ACCESSORIES • Additional router bits

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION The machine which works with motor–belt mechanism, ideal for the serial end milling operations on aluminum and PVC profiles precisely. High quality end milling operations by means of the adjustable motor speed thanks to the inverter and potentiometer. Practical change of cutter provides ease of operation Fixing the workpiece firmly and at square by means of the vertical clamps and adjustable horizontal supports Safety operations with safety guard Cutter storage location in front of the machine Robust machine stand and support arms in front of the machine to provide end milling of profiles up to 2.5 meters Practical cutter adjustment by means of the gap parts Max. end milling profile height (H): 210mm Max. end milling stroke (W) : 615 mm Max. saw blade diameter: Ø185 mm Max. tool height : 150 mm STANDARD ACCESSORIES • 12x pneumatic vertical clamps with adjustable pressure valve • 6 x adjustable horizontal supports • Air gun

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION CA 603 Single Corner Cleaning Machines are used for striping of bottom and top surfaces and cleaning outer corners of 90° PVC cleaning profiles. High quality stripping and cleaning operations by means of the hydro-pneumatic system Profile processing capability up to 180 mm of height Practical change of cutter provides ease of operation Fixing the workpiece firmly by means of the vertical and horizontal clamps Stops automatically after stripping and cleaning operation PLC operation system Centering system to fit the profiles properly on the setsquare Robust machine stand Pneumatic tool fixing and releasing system Stripping blade levels are adjustable according to laminated and un laminated profiles Processing capability of 2 different PVC profile 4 different cutter set can be mounted on a modul (CA 603) STANDARD ACCESSORIES Air gun OPTIONAL ACCESSORIES Corner cleaning cutters Videolar TECHNICAL SPECIFICATIONS 1200Wx 2~3 400V AC 50-60 Hz. 3000 D/dak RPM

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION After welding clean up down and corner sides of 90º PVC Profiles after welding. High quality stripping and cleaning operations by means of the hydro-pneumatic system Profile processing capability up to 180 mm of height Practical change of cutter provides ease of operation Fixing the workpiece firmly by means of the vertical and horizontal clamps PLC operation system Centering system to fit the profiles properly on the setsquare Robust machine stand Stripping blade levels are adjustable according to laminated and un laminated profiles Pneumatic tool fixing and releasing system Single or multi cleaning operations can be processed Automatic start up feature when profile placed on the table Stops automatically after stripping and cleaning operation STANDARD ACCESSORIES Air gun OPTIONAL ACCESSORIES Corner cleaning cutters Videolar TECHNICAL SPECIFICATIONS 1200 Wx3 400V AC 50~60 Hz 3000 D/dak RPM D: 215 d: 32 mm. 36 Lt/dak. 6~8 Bar 92x 101x 143 cm 249 kg. 198 kg.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION DC 421 MS is designed for the strait or angular cutting operations of large size of profiles made of aluminum and PVC materials by means of double head sawing units equipped with Ø 420 mm of saw blades. Two-hand run safety operation Manual adjustment of intermediate tilting angles from 90° to 45° inwards Hydro-pneumatic saw blade feed Cutting accuracy +/- 0.2 mm Manual positioning of cutting units Solid steel construction of the body Conveyor & 2 x pneumatic profile supports Automatically closing safety guards Horizontal pneumatic material clamps to ensure optimum material fixing STANDARD ACCESSORIES • Equiped with Ø 420 mm of saw blades • Roller conveyor & 2 x manual profile supports • 4 x horizontal clamps • Air gun • Spray saw blade lubrication system OPTIONAL ACCESSORIES • Profile Length Stop for cutting short pieces (DKN 70 with digital unit, DKN 71 with ruler) • Machine with the length of 5m and 6m • VCE 1570 Chip vacuum extractor

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION CK 412 is an automatic saw blade machine which is ideal for cutting operations of the PVC glazing beads at 45°. Adjustable saw blade feeding speed Pneumatic saw feed by pushing button Equipped with 2x pneumatic vertical clamps Automatic return to start point of the process Twin blade design 8 glazing beads can be cut simultaneously using single mold without problems STANDARD ACCESSORIES 1x Ø 200 and 1x Ø 103 mm saw blades KN 152 roller conveyor Air gun OPTIONAL ACCESSORIES Clamping device for special glazing beads Additional saw blades Digital Roller Conveyor with Automatic Stop (SKN 301) SKN 300, SKN 450,SKN 600 conveyor SKN 301, SKN 451, SKN 601 conveyor Videolar TECHNICAL SPECIFICATIONS 1200 W x2 400V AC 50~60 Hz 3.000 D/dak. RPM D1:103 mm D2:200 mm d:30-32 mm 6~8 Bar 35 Lt. / dak. 54x113x124 cm 168 kg 134 kg

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION ACK 700 is designed for the strait or angular cutting operations of the large size of profiles made of aluminum materials by means of Ø 700 mm of saw blade. Two-hand run safety operation Location points at 75°,60°,45°,30°,22.5°,15°,0° both left and right Pivoting range from -75° left to +75° right infinitely adjustable Hydro-pneumatic saw feed Adjustable saw blade feeding speed Interior LED lighting Pneumatically opening safety guard Safety locking switches on top guard and front doors Double acting clamps for operator safety STANDARD ACCESSORIES • Equipped with saw blade Ø 700 mm& 4 Kw motor • Spray saw blade lubrication system • MKN 301 roller conveyor (3 m) • 2 x vertical and 2 x horizontal clamps • Air gun OPTIONAL ACCESSORIES • Additional saw blade Ø 700 mm • VCE 1570 Chip vacuum extractor • SKN 300-450-600 conveyor • DKN 302-452-602 conveyor • Laser marker set for 90 ° of cutting operation TECHNICAL SPECIFICATIONS 4kW - 3P 400 V 50~60 Hz

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION ACK 550 is designed for the strait or angular cutting operations of the large size of profiles made of aluminum materials by means of Ø 550 mm of saw blade. Two-hand run safety operation Location points at 75°,60°,45°,30°,22.5°,15°,0° both left and right Pivoting range from -75° left to +75° right infinitely adjustable Hydro-pneumatic saw feed Adjustable saw blade feeding speed Interior LED lighting Pneumatically opening safety guard STANDARD ACCESSORIES • Equipped with saw blade Ø 550 mm • Spray saw blade lubrication system • MKN 301 roller conveyor (3 m) • 2 x vertical and 1 x horizontal clamps • Air gun OPTIONAL ACCESSORIES • Additional saw blade Ø 550 mm • VCE 1570 Chip vacuum extractor • SKN 300-450-600 conveyor • DKN 302-452-602 conveyor • 1 x horizontal clamps • Laser marker set for 90 ° of cutting operation Videolar TECHNICAL SPECIFICATIONS 4kW - 3P 50~60 Hz 400 V 2400 D/Dak. RPM D: 550 mm d:30 mm 6~8 Bar 160 Lt/dak. 106x131x156 cm 419 kg 373 kg

Request for a quoteResults for

Air guns - Import exportNumber of results

36 ProductsCountries

Company type

Category

- Ionisation equipment - air (4)

- Electrical & Electronic Components (3)

- Paint spray guns and accessories (3)

- Rubber products (2)

- Automation - systems and equipment (1)

- Cleaning machines, industrial (1)

- Cutting - machine tools (1)

- Electronics - import-export (1)

- Greasing equipment (1)

- Hoses, pipes and tubes - plastic (1)

- Laser - cutting and welding machines (1)

- Milling - machine tools (1)

- Nailguns, pneumatic (1)

- Nails and tacks (1)

- Stapling and nailing - machinery and equipment (1)

- Sterilisation and disinfection - medical equipment (1)

- Surface treatment - machinery and equipment (1)

- Vehicle maintenance products (1)