- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cantilever

Results for

Cantilever - Import export

RACK CONCEPT

Belgium

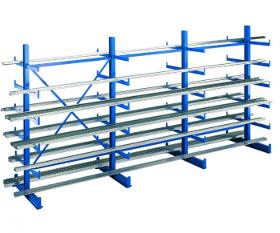

Specially designed for storing materials of great length or varying dimensions, they consist of a structure made up of columns and a series of cantilever arms for depositing the load.

Request for a quote

LIBERTY LLC

Russia

The modern embodiment of traditional forms. Accord console is part of a modular system, which makes this collection extremely flexible. The threaded legs have 3 standard sizes, which allows you to make any piece of furniture within the concept, preserving a visual static unity of forms.

Request for a quote

SCHULTE LAGERTECHNIK

Germany

The K 1000 cantilever racking sets provide you with everything you need for the efficient storage of lightweight items. Thanks to welded-on arms with a load capacity of 200 kg each, this cantilever racking is exceptionally quick to assemble by hand. The K 1000 cantilever racking sets are also available immediately ex stock and are therefore an excellent solution when it comes to setting up and expanding your warehouse. — Placing and removing items using storage and retrieval systems and industrial trucks — Racks available in any length and as single and double-sided variants — Welded-on cantilevers with end stoppers — Maximum load per cantilever: 200 kg — Height: 2000 mm / arm depth: 500 mm / width: 1250 mm — Stable ground anchoring thanks to supplied heavy-duty anchors — RAL 5010 gentian blue

Request for a quote

OHRA-REGALANLAGEN GMBH

Germany

Cantilever racking systems are highly load-bearing storage systems intended for storage of long and/or bulky storage materials. Such goods include timber, wooden boards, metal sheets, sections, beams or steel elements, building materials but also scrap cars and all kinds of heavy loads. Cantilever racking by OHRA is distinguished from standard racks using solid steel sections for all load-bearing elements. Thanks to this slim construction of our racks a high storage capacity can be achieved across a small floor space. There are specific types of cantilever racks for every product and for every industry. They differ based on requirements, height, useable depth, load-bearing capacity or section thickness. All cantilever racking are produced individually according to customer requirements; they are equipped with a high-quality powder coat or hot-dip galvanised for outdoor storage.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

They consist of two steel clamped or monobloc rollers mounted on a single “V”-folded shaft. They have the upper bearing mounting heads with hermetic closure and the lower ones, with protruding shaft, with labyrinth dust protection. The shaft is locked in the housing of the central bracket.The latter, with a base plate fitted with mounting holes, is made of cold-formed steel sheet.They are used in concave belt conveyors that operate, even in bad environmental conditions, at medium-high speed, with medium loads and sizes.

Request for a quote

ONE2ID B.V.

Netherlands

Cantilever rack labels, for the most part, have to be able to withstand challenging conditions. Therefore, labelling cantilever racks, also known as long-item racking, can pose a challenge compared to labelling standard pallet racking shelves and beams. It is not uncommon for warehouses that store long and/or heavy-duty goods to have to deal with a more than average share of dust and dirt. As a result, the type of material you choose for your rack labels should be sturdy and durable. Another point of interest that requires careful consideration when labelling cantilever racks is the placement of the labels on the cantilever arm. The label consultants at ONE2ID are on hand to help you find a suitable solution.

Request for a quote

STORETECH ALJAZIRAH METAL

Turkey

In narrow aisle racking systems, the aisles are narrowed in order to use the storage volume horizontally and more efficiently. Many factors are highly important in choice of narrow aisle racks. These are the type of material to be stacked, the type of forklift to be used, the storage speed and the importance of the storage floor. In the narrow aisle racking system, there are guide rails fixed to the sides of the aisles. Inductively system installed inside the base (electronic tracking system) through the stacking method is made ready for use. Narrow aisle racks have many advantages. Stacked material is the first of these to provide fast and direct access. The fact that the circulation of materials can be done quickly and used to the maximum level from the storage area is among other advantages.

Request for a quote

STORETECH ALJAZIRAH METAL

Turkey

HEAVY DUTY CANTILEVER This storage system is so versatile that different component combinations can be used in various situations. the cantilever arms can be easily adjusted in height. The system comes in blue as standard, but other colors are available on request. For outside installations, external paint is available or a hot dip galvanized solution can be provided where a corrosive environment is present

Request for a quote

STORETECH ALJAZIRAH METAL

Turkey

STORETECH LONGSPAN SHELVING Longspan shelving is designed for warehouses where goods are deposited and removed manually from shelves. This system also make optimal use of warehouse height, as the higher levels can be accessed mechanically by devices that lift the operator to the required height (stacker cranes or order picking forklift trucks) or via gangways located between shelves It is also common practice to set up a mixed warehouse of picking and pallet storage, where the top shelves are used to keep palletised stock reserve and the bottom is intended for picking

Request for a quote

GUANGZHOU HEDA SHELVES CO., LTD

China

Cantilever racks are composed of upright columns, cantilever beams, base and connecting rods. Cantilever rack is suitable for storing long material, annular material, plate, pipe and irregular goods.

Request for a quote

WELTOP MACHINERY

Turks And Caicos Islands

The structure of cantilever centrifugal casting machine is horizontal. It is made up of engine, electric control system, water cooling system, hydraulic ejector mechanism and Safety protection cover. It can be widely used in large diameter sleeve and cylinder castings production. Technical specification name of parameterparameter valuesunit Casting maximum diameterΦ800mm Casting minimum diameterΦ500mm Casting maximum length600mm The maximum load(mold+cating)1tons Speed of mold0~1000rpm Main machine power of motor22kw Hydraulic pump motor power4kw Ejector force100kn Ejector stroke300mm

Request for a quoteResults for

Cantilever - Import exportNumber of results

13 ProductsCountries

Company type

Category

- Shelving, storage (4)

- Racks and bins (1)

- Bar codes - printing machines (1)

- Bearings - ball, needle and roller (1)

- Components and parts for small household appliances (1)

- Cutting - steels and metals (1)

- Cylinders - combustion engines (1)

- Furniture, household (1)

- Office shelving and filing systems (1)

- Storage equipment and systems (1)