- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coating machinery

Results for

Coating machinery - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Vacuum metalizing coater for plastic, glass, ceramic, stainless steel, metal etc. The coating experts of your own company. Full set solution for the coating production. We can help you to enter the pvd coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements. We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production. Easy to implement. To many people unfamiliar with the process, pvd coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. We developed a turnkey coating process that makes a pvd coating centre easy to implement. A complete coating process consists of several steps: stripping ; pre-treatment; quality control; cleaning & drying; fixturing&visual inspection; pvd coat ;quality control & thickness measurement etc

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

We use this vacuum degasser to clean all kinds of products before do the coating. This degas chamber is venting the gas,air and other impurities through putting in the heated N2. This vacuum degasser will greatly shorten the vacuum time, reduce the oxygen corrosion, protect the machine and prolong the life time of the equipment. It enhances the adhesion of the film in the products.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Shoes Heel Vacuum Coating Machine/Shoe Heel Metallizing Plant/shoe Heel Metallization Machinery

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Mid-frequency magnetron sputtering technology has gradually become the mainstream of sputtering coating technology. Coating: Multi-function metal coating, composite membrane, transparent conductive coating, Increase return to shoot coating, electromagnetic shielding coating, decorative coating, etc. Power supply: DC magnetron sputtering power supply, MF sputtering power supply, high pressure ion bombard power supply. Target: DC magnetron sputtering target, MF twin targets, planner target, cylinder target. Vacuum chamber structure: Vertical signal door, Vertical double doors. Pump system: Molecule pump (diffusion pump)+Roots pump+ Holding pump(optional: turbo pump, poly cold system) Air system: Mass flow controller (1-4road) Ultimate vacuum: 6x10-4pa (no-loading, clean chamber) Pumping time: No-loading from air to 5x10-3pa<13mins Workplace motion mode: 6 axis/8axis/9axis public and self-rotation

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

hollow cathode ion coating equipment

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Jewelry ion spray chrome Coating machine/jewelry pvd vacuum coating equipment,pvd plating machine

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Contactless application ▪ Suitable for lubricants, greases, anaerobic and other adhesives ▪ Materials with low as well as high viscosity applicable ▪ vipro-SPIN feeded by ViscoTec 3RD3 or 3RD4 dispenser ▪ Four different spinning heads available ▪ Continuous spraying ▪ Easy integrateable to different control unit systems due to open end cable

Request for a quote

PLANSEE SE

Austria

Molybdenum sputtering targets are used for the manufacture of thin-film transistors used in TFT-LCD screens. Targets from Plansee are maximum dense, highly pure and show a homegenous microstructure. Therefore higher sputtering speeds, minimized particle formation during the process and homogenous layers are guaranteed. Available molybdenum alloys: MoTa, MoNb, MoNa, MoW You can choose between our single and multi-piece planar targets. Planar targets are available for all commonly used systems as well as to specific customer needs. Rotary targets are available too.

Request for a quote

NET D.O.O.

Slovenia

Professional, accurate and aesthetically pleasing flocking of different types of materials, size and colors, on surface of your choosing. Flocking is the application of small pieces of fibers (the so-called flakes), with the help of the electrostatic surface on which we have previously applied special glue. All of the contents are water based and pose no threat to the environment. The end product is a soft protective coat, pleasant to touch, that comes in a color of your choice and if exposed to higher temperatures the coating protects the user from harm (for example it protects against burns, from coming in contact with hot metal). Advantages: - the final product is protected and feels soft to touch, - flakes can be applied to most materials, we mainly flock metal parts that come in different shapes and sizes, - flakes come in different colors.

Request for a quote

NET D.O.O.

Slovenia

With the most modern equipment, extensive knowledge and years of experience, we offer superior powder coating service. Powder coating is an application of the paint in the form of a powder to the surface of the workpiece or metal. Because it is a so-called dry powder coating, the adhesive is not applied, but rather the coat itself takes its place. Electrostatic gun is used to apply the powder, which is then exposed in a furnace at high temperatures, melting the coat and when cooled down, we have a smooth homogeneous surface, which is solid and robust. Powder coating is mainly used on metal products, since it has to be exposed to certain higher temperatures. We are high in demand of coating steel products, aluminum products and stainless steel material, but other metals are also suitable for powder coating.

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Our company provides design, manufacturing and installation of turn-key customer based.powder coating solutions.

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Automatized solutions for powder coating and liquid painting

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Design, manufacturing and installations of customized and product based industrial painting line solutions

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

The powder coating booth is designed for easy and fast color changes during the operation. Different than the conventional powder coating booth systems, it have on it additional systems in order to make the booth fast cleanable. As the most important problem at the conveyorised powder coating systems is color changing time, this powder booth model is the most efficient solution. ADVANTAGES Fast and easy color change; Efficiency 97-98%

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Tunnel type ovens are convection ovens which allows to electrostatic powder coated work pieces to be cured usually around at 180-200°C in 10 minutes, are used in the powder coating systems. Curing oven length is calculated according to the conveyor speed in order to achieve polymerization and curing of the work piece quantities per shift. The powder coating ovens are designed by us according to the shape, quantity and weight of the product to be cured. These ovens are conveyorised, product inlet and outlets are opened designed accordint to the biggest work piece sizes. Oven can be designed as a tunnel, U, S or W-shaped according to the biggestt work piece and the work shop sizes. Electricity, liquid or gas fuel is used for heating up the ovens.

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Simple and efficient machines, designed for electrostatic powder coating applications with frequently color change within the day. Powder suction is directly from powder coating box that maintains easily fast color change. The equipment is movable, the body consists of a console and a chassis with a vibration table where powder box can be placed. Powder suction is achieved using a conductive pipe that maintains perfect fluidization inside the powder box and a powder injector above it. Powder coating equipment is CE certificated and conforms to the European Norms.

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

The oven is specially designed for the transfer process that works with the sublimation principle to give wood, marble or special effects to the outer surface of aluminum profiles and sheets. The pattern on a polyester film is transferred to the outer surface of the previously base powder coated aluminum profiles or sheets using vacuum application and heat. Wood effect transfer system consists of a trolley with special vacuum heads, a vacuum pump system, sublimation oven with circulation system and fully PLC control system.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ONCEL CNC MAKINE

Turkey

JAMB MORTAR COATING MACHINE can cover all facade coverings and rafters from 30 to 560 mm width. Assembly and disassembly of the mold is easy. 70 kg capacity mortar reservoir cleaning is very simple

Request for a quote

ENDUSTRI GM

Turkey

ENDÜSTRİ GM Dust Collection Systems are designed for all kinds of applications and appeal to many sectors. By using it in closed areas, in dense dusty environments, it ensures that the environment is made dust-free and thus, the surface is seen more clearly and thus, the surface quality is increased. At the same time, environmentally friendly machines filter the dust in the environment and throw it cleanly into the atmosphere.

Request for a quote

ENDUSTRI GM

Turkey

ENDÜSTRI-GM Vacuum Machine is a machine that contributes a lot to the business. During the sandblasting, it collects the granules falling back to the ground, separates the granules it collects, filters the dust and throws it cleanly into the atmosphere. It makes the cleaned granules ready for sanding again. This transformation makes a significant financial contribution to the business in terms of man / hour and granule cost.

Request for a quote

MASCHINENBAU BARDOWICK GMBH

Germany

The powder coating machine EPC is designed for the powder coating of cables, hoses and profiles up to a max. diameter of 150 mm and line speeds of up to 1,500 m/min. Our filter cleaning system already patented in 2004 ensures 100% dust-free machine environment. Maschinenbau Bardowick GmbH (formerly DCM Maschinenbau GmbH Lüneburg) has been the world’s leading manufacturer of these powdering machines for decades. Numerous customer-specific special requirements have been developed and implemented by us. The Advantages of the Powder Coating Machine EPC Safe adhesive forces on the product by using electrostatic powder guns with up to 100 kV. 100 % dust-free machine environment Optional fine dosing for powdering with minimum quantities High efficiency at simple operation, The Powder Coating Machine EPC at a glance Cable Powdering with Highest Quality The application of talcum and other powders as separating agents between the individual layers of the cable is no trivial task nowadays.

Request for a quote

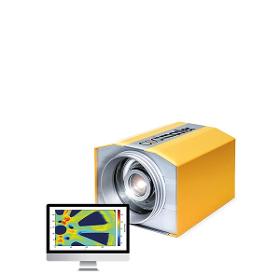

COATMASTER

Switzerland

Decrease setup time for your process. Save material. Document continuously.

Request for a quote

COATMASTER

Switzerland

Just pick it up and start measuring. This handheld is the most innovative one in terms of contactless coating thickness measurement. Would you like to measure the coating thickness early in the process in order to save material and avoid coating mistakes? Then the coatmaster Flex is the right measurement device for you. Optimize your process and get your coatmaster Flex now. If you are not completely satisfied within the first 30 days after delivery, you can return it free of charge.The coatmaster technology (ATO) allows the thickness of the coating to be measured immediately after application. The technology operates contactless and non-destructive without dangerous emissions and is suitable for coating metal, paper, rubber, ceramics, glass, plastic and wood surfaces.

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

Coated track plates for use in crawler tracks for construction machinery. The extremely wear-resistant polyurethane Intec E provides the necessary mechanical properties for use in the crawler and protects the floor from the high machine weight. Up to 1.5 m length possible!

Request for a quoteResults for

Coating machinery - Import exportNumber of results

25 ProductsCompany type