- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- continuous forms

Results for

Continuous forms - Import export

PRINTING HOUSE SPRECOGRAF

Poland

We make self-copying pads, self-copying forms, waiter's pads, continuous printing on computer folds.

Request for a quote

UMMANMAK

Turkey

Asphalt plants create the hot mix material by mixing different types of aggregate, bitumen and filler. The advantage of our continuous type asphalt plants is production high quality asphalt, because of very sensitive dosing with accordance to recipe accepted in your country. - Number of different aggregates : 4-5-6 - Mobility : Stationary and Mobile type - Capacity offered : 80 - 120 - 160 tph - Hot asphalt storage bunker : optional - Bitumen tanks : you can purchase from us, as well as from domestic market - Aftersale Service : can be provided from Turkey and Algeria - Operation System language : English - Russian - Turkish - French You can contact us any time. We can speak in English, Russian, Turkish, French and Arabic to make you feel comfortable.

Request for a quote

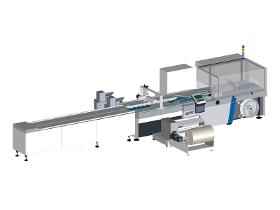

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Paper or film? Stay flexible! A single machine can now deliver both film and paper packaging applications. The continuous Form Fill and Seal Machines paper X hybrid are designed for packaging goods in paper or film. A simple changeover ensures you are ready for the new product and the new packaging material. Whether using a chain infeed or infeed conveyor, the machines stand apart through their continuous packaging process – without stop-and-go – maximising efficiencies by ensuring there is no downtime when sealing or glueing. Our paper packaging solutions are available in different versions, depending on how flexible you need to be: - the basic model paper X features paper packaging with overlap on top - the paper X hybrid features paper and film packaging with overlap on top - the paper X hybrid advance features paper and film packaging with overlap on top and side seal

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The continuous Form Fill and Seal machines servo X 800 are the most flexible and powerful of film packaging machines in the large-format segment – and all this with maximum modularity. The machines can be configured individually and thus meet all requirements. They are designed for packaging large-format products with a width of up to 800 mm and a length from 150 mm. Whether chain infeed or infeed conveyor, the machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled. Depending on customer requirements, these packaging machines are equipped with different control systems.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The continuous Form Fill and Seal machines of the servo X series are available in five performance ranges and numerous variants. They cover the broadest possible range of horizontal film packaging applications for various industries – and all this with maximum modularity. The machines can be configured individually and thus meet all requirements for the desired performance or type of packaging. Depending on the machine variant, several packaging styles can be flexibly produced with one machine. Whether chain infeed or infeed conveyor, servo X machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ILK IHRACAT AS.

Turkey

Slabs produced by continuous casting method form hot rolled coil sheets with thicknesses ranging from 1.40 - 25.00 mm after special heating processes. These products are used as raw materials in many industrial sectors such as Pipe-Profile, Building Industry, Machinery Manufacturing, Industrial Shelf/Storage Solutions, Shipbuilding, and Agricultural Machinery. Product Specifications: S235JR, S235J2, S235J0 S275JR, S275J2, S275J0 S355JR, S355J2, S355J0 Advantages Offers diversity with a wide range of thicknesses. Slabs produced by continuous casting method reach high performance with special heat treatments. It provides the opportunity to use as a reliable raw material in various industrial sectors. Hot Rolled Steel Coil (HRC) is a versatile solution that meets various needs in the industry. This product, which stands out with its high quality and wide range of uses, is ideal for creating a reliable basis for your projects.

Request for a quote

GABELLA MACCHINE SPA

Italy

Cut-to-length lines for T-shaped panels Slitting and recoiling lines with automatic separators positioning Dedicated plants for pre-painted,? film-coated or other special materials (stucco-design, mesh, ground surfaces…) Special lines for panels production, with punching, shearing, roll-forming and bending Continuous punching lines Spool recoiling lines De-burring lines Combined lines with partial cut, where a part of the strip is recoiled for future use Machines for mass production or very flexible plants for small productions Cut-to-length and recoiling lines, with coils packaging stations. Customized and very enhanced productions, which integrate the sheet-metal processing with rotating turret punching (possibility of up to 24 different tools? a time, even in “multitools” solutions) or fiber laser cut.

Request for a quote

TEKNOVA PRINTING AND CHEMICAL INDUSTRY TRADE

Turkey

The SLB T-Form is self-adhesive blanket, designed for general Continuous – Business Forms application and provides excellent printing qualities; the blanket is compatible with UV and conventional inks. PROPERTIES The blanket can be easily adhered / removed from different substrates, metal cylinder or blanket, and easily repositioned after initial mounting. Once tightly clung, it provides excellent stability at high press speeds and resists most press chemicals. No residual adhesive remains on the press cylinder after blanket removal. APPLICATION Conventional Hybrid * The information on this technical data sheet is based on our general experience. The tests are carried out under controlled

Request for a quote

TEKNOVA PRINTING AND CHEMICAL INDUSTRY TRADE

Turkey

The Advantage is a revolution in the development of offset printing blankets for the printing industry. The characteristics of its unique construction, which is based on the cord carcass, brings outstanding advantages up to 30% saving in comparison with standard offset printing blankets in the printing process. Specially formulated for UV curing inks on sheetfed presses, continuous forms presses and dry offset applications PROPERTIES Specially formulated, image visible red surface. EPDM polymer responsible for high resistance to swelling against non-aggressive UV drying inks and cleaning agents. Ghosting/embossing from previous jobs is eliminated. Not recommended for use with daylight fluorescent inks and metal-pigmented inks. Its unique compressible design reduces surface smashes and markings created by rigid substrates such as; metals, plastics and boards. Almost no sinking or stretching giving the blanket exceptional dimensional stability.

Request for a quote

SPEEDO LTD

Bulgaria

The barrier is made of hot-dip galvanized steel tubing. The legs are fixed to the body. It consists of a body, the frame of which is made of a tube with a 32mm diameter and a grid, formed by vertical bars with an 8mm diameter. At one end of the grid are welded hooks, and at the other there are loops which are used to attach the barriers to one another until the desired length is achieved. The legs are the continuation of the tubes which form the body, which ensures the stability of the barrier. The barriers are delivered arranged in a package and fastened with a metal strap. As an additional service, light reflecting panels can be mounted on the barriers, as long as they are provided by the client.

Request for a quote

SPEEDO LTD

Bulgaria

The barrier is made of hot-dip galvanized steel tubing. The legs are fixed to the body. It consists of a body, the frame of which is made of a tube with a 32mm diameter and a grid, formed by vertical bars with an 8mm diameter. At one end of the grid are welded hooks, and at the other there are loops which are used to attach the barriers to one another until the desired length is achieved. The legs are the continuation of the tubes which form the body, which ensures the stability of the barrier. The barriers are delivered arranged in a package and fastened with a metal strap. As an additional service, light reflecting panels can be mounted on the barriers, as long as they are provided by the client.

Request for a quote

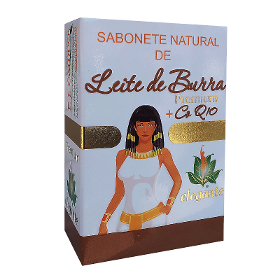

F.J.CAMPOS

Portugal

FJCAMPOS as a soap manufacturer is counting on the quality of its products as they are made with 100% vegetable ingredients, they are animal friendly and as well as being elegantly produced they are packaged by hand. The company currently has about 29 of its own brand soaps available. Donkey Milk is rich in milk proteins, vitamins A and E, calcium and minerals, it has restorative and renewing properties, contributing to the elasticity and vitality of the skin, which results in a younger and more beautiful skin. Donkey milk has proteins that, in addition to moisturizing, help to form a continuous film on the surface of the skin, which causes smooth skin. The Q10 Coenzyme, is a strong antioxidant that protects the skin from aging, and helps eliminate spots and wrinkles.

Request for a quote

ECKOLD GMBH & CO. KG

Germany

ECKOLD Kraftformer KF 170 PD - Universal forming machine for stretching, shrinking, reforming, curving, planishing, flattening, doming, straightening, punching, notching and clinching. The Kraftformer KF 170 PD with pneumatic drive is the most compact of all ECKOLD Kraftformers. The machine is designed for single or continuous stroke operation for forming steel sheets with a thickness of up to 2 mm. Operated in single stroke mode, the KF 170 PD is the ideal machine for reworking and adjusting tasks. It can be used for punching, notching and clinching. In continuous mode, the KF 170 PD allows for fast and easy forming. In single stroke mode, it caters for precision hole punching, clinching and reworking! For our Kraftformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Max. forming capacity Steel 400 N/mm²: 2.0 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.5 mm Contact us for a customised offer, tools included!

Request for a quote

PRINTING HOUSE OPTYS

Czech Rep.

The CONCEPTA and PERFECT Rotatek rotary machines can print paper from roll to roll, roll to sheets, or from roll to continuous form (zic zak). Pilot holes or loading holes, embossing, perforations (both longitudinal and transverse) and numbering can be added to products printed in our rotary machines. Technical specifications 9 colours cylinder circumferences of 24" and 25" offset and flexo are combined in one single pass through the machine min / max width of the printable material 210 mm / 500 mm min / max weight printable paper 53 g/m2 / 200 g/m2 UV drying for immediate further processing iris printing

Request for a quote

JELIGHT COMPANY

Croatia

The UVO method is a photo-sensitized oxidation process in which the contaminant molecules of photo resists, resins, human skin oils, cleaning solvent residues, silicone oils, and flux are excited and/or dissociated by the absorption of short-wavelength UV radiation. Atomic oxygen is simultaneously generated when molecular oxygen is dissociated by 184.9 nm and ozone by 253.7 nm uv. The 253.7 nm UV radiation is absorbed by most hydrocarbons and also by ozone. The products of this excitation of contaminant molecules react with atomic oxygen to form simpler, volatile molecules which desorbs from the surface. Therefore, when both UV wavelengths are present atomic oxygen is continuously generated, and ozone is continually formed and destroyed. By placing properly pre-cleaned samples within five millimeters of ozone producing UV source, such as the low pressure mercury vapor grid lamp in the UVO-Cleaner ®, near atomically clean surfaces can be achieved in less than one minute.

Request for a quoteResults for

Continuous forms - Import exportNumber of results

16 ProductsCountries

Company type

Category

- Sealing and wrapping - machinery and equipment (3)

- Varnishes (2)

- Bridges, metal (1)

- Construction - Machines & Equipment (1)

- Continuous printing (1)

- Detergents and soaps - professional (1)

- Forming - steels and metals (1)

- Laboratory equipment and instruments (1)

- Metals - Machines & Equipment (1)

- Offset printing machinery (1)

- Paper, self-copy (1)

- Sealing rings (1)

- Steel, carbon (1)

- Steel, tool (1)