- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packaging machine

Results for

Packaging machine - Import export

BELGOMILK IA SA

Greece

The cup falls Feeding station Aluminum placing (preset cap) Waterproofing Dating Carrier’s exit Automatic date placement The cup filling machine has three photocells A photocell to check the filling whether there is any cup or not. Thanks to this photocell system, the machine will not lose the product. If there are no cups, then the machine will not proceed with filling. The photocell control for the aluminum lids, whether there is cup or not, thanks to this system if there is no cup then the machine will not waste the aluminum lids. The photocell control for sealing, thanks to this system it checks whether there are aluminum lids on the cups or not, if there are no lids on the cups then the machine will not reach the sealing unit and the machine stops.. Additional options are possible in the yogurt filling sealing machine Flow filter unit-ΗΕΡΑ Second filling station for filling multiple products Adjustment of placement between cap and cap

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The perfect thermoformer for packing your sliced products Whatever you slice – wePACK: Right from the start, the development of the wePACK was focused intently on the requirements of our customers. The result is a packaging machine which is consistently geared to slicing applications and which delivers maximum output, as well as ease of operation and servicing. Thanks to its hygienic design and a high level of automation, the wePACK guarantees maximum food safety. From product preparation to quality checked primary packaging, we offer everything from a single source. This unique situation takes the integration of slicers, automation, packaging and end-of-line equipment to a new level. Weber combines strong single components to even stronger complete line solutions. The boundaries between individual components disappear, so that the complete slicing line merges into one unit. NEW: Optimized software for the integration of infeeding systems

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

With the servo X e-com you are ideally equipped to meet the demands of film packaging for the e-commerce, mail order and logistics sectors. Whether dealing with the direct dispatch of individual goods, packing groups of products or meeting the complex requirements of returned goods packaging for example, the servo X e-com packs goods with a minimum use of film and automatically adjusts the film bags with four sealed sides to the product's length as standard. To support the precise fitting of shipping bags, the servo X e-com fit model also adjusts the bag size to the product's width so that the machines fully automatically adjust to varying product sizes during the packaging process. Furthermore, packaging with upper and lower film enables a greater scope for branding, for example with two-tone shipping bags. Additional options include the ability to add an easy-opening perforation to the bags as well as inserting a double-sided adhesive tape for resealing a bag for returns.

Request for a quote

SOLLEX AB

Sweden

Ceramic coated injector blade in stainless steel for plastic film manufacturing. The fine structure enables the coating to protect the edge as long as possible. Ceramic coating is therefore advantageously used to cut white plastics. The injector blade with a thickness of 0.25 mm is a strong and small blade with high durability. For finer and thinner cuts, Sollex recommends ceramic coated industrial razor blade (2-013-K). Suitable for: White plastic film with a high percentage of chalk Dimensions: 38 x 8 x 0.25mm Grinding: Single edge Two sided Single bevel

Request for a quote

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

Maximum automation – for the 38 – 160 mm calibre range at up to 160 cycles per minute in continuous mode The FCA 160 offers unrivalled versatility combined with highest automation. It closes collagen casings up to 90 mm, fibrous casings up to 120 mm and plastic casings up to 160 mm (depending on the material thickness). Subject to technical modifications.

Request for a quote

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

25 % productivity increase – Automatic Clipping/Hanging Machine for looped products (sausage, cheese) The FCHL ensures continuous production and therefore an increased output rate. The automatic double-clipper with integrated hanging line efficiently combines four processes in a way which saves on manpower: clipping with simultaneous looping, hanging the loop and positioning (suspension) on the smoke stick. Subject to technical modifications.

Request for a quote

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

Gain in efficiency – sealing and clipping with one machine The TSCA Automatic Sealing/Clipping Machine processes flat film from a roll into a ready-to-fill tube which is securely closed by the integral clipping unit. All commonly used films, coated or uncoated, as well as laminates can be processed. The film rolls used can be up to 3,000 metres long. Subject to technical modifications.

Request for a quote

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

Air-free slack filling – calibres up to 200 mm The ICA is the ideal machine for large calibres and moulded products up to a calibre of 200 mm. Fibrous, collagen and plastic casings can be processed. The innovative iris separator makes the ICA ideal for the production of large volumes like slicer products, moulded ham, even those made of whole muscles. Subject to technical modifications.

Request for a quote

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

Entrance into FCA class – for a range of calibres from 38 to 160 mm and up to 125 cycles per minute in continuous mode The FCA 80 is a robust entry-level machine with simple functions that is easy to operate. With four different spreadings the clipping machine offers maximum flexibility. The automatic double-clipper FCA 80 closes collagen casings up to 80 mm, fibrous casings up to 100 mm and plastic casings up to 160 mm (depending on the material thickness). Subject to technical modifications.

Request for a quote

WECKERLE MACHINES

Germany

Lipstick Filling and Processing Line The L 1800 is a sustainable and economical solution to serve all types of manufacturers of cosmetic products. The very compact L 1800 is able to produce up to 1.800 lipsticks per hour in 24/7 operation. Furthermore, the machine can be upgraded very cost-efficient for producing top filled products such as lipgloss, making it our most compact multi-functional machine available. Features: Weckerle Soft Mold Lipstick Molding Technology, Ergonomically comfortable machine with simple and intuitive handling, Small footprint enables highly efficient use of workspace, Innovative quality inspection camera

Request for a quote

OPTIMA LIFE SCIENCE GMBH

Germany

- Modularity: Quick change and addition of modules - Scalability: Machine can be extended from an entry level machine to a fully-automated production line - Intermittent motion: Lab machine - Continuous motion: Pilot plant production - Continuous motion, multiple lanes: Large volume production Applications - Product development - Manufacturing of product samples - Clinical tests - Market launch - Production Perfect for new products and business areas - Covers small and medium production needs

OPTIMA CONSUMER GMBH

Germany

Filling - Filling systems coordinated to the product - Freely programmable filling nozzle movement and filling speed for below/over or bottom-up filling Containers - Container classification using a portioning device - Container transport using pucks for flexible production and fast conversion - Container transport without pucks possible - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport - Very gentle processing of the containers - Processing different container shapes Design - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Running direction of the machine from left to right - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system

OPTIMA CONSUMER GMBH

Germany

Containers - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification using a rotary feeder - Container transport using pucks for flexible production and fast conversion - Container transport without pucks possible - Cycled container transport - Very gentle processing of the containers - Processing different container shapes Shapes -User-friendly, fast and primarily tool-free format change Design - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Secure and sturdy mechanical system Drive - Drive via wear-free servomotors Manufacture/Closing - Positioning the caps manually for semi-automatic processes - Closing systems coordinated to the product

RIDZEWSKI GMBH

Germany

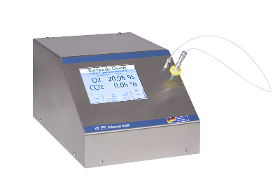

The EPC Spot is our measuring device for a random check of the gas levels of O2/CO2 in packaging or packaging machines. A sample is taken by a special needle. Due to the small amount of gas the analyser needs for the measurement, blister packs or ampoules can also be tested. As a user, you can enter several limit values for different products in the device. The result is then additionally visualised in red or green. All measurements are stored in the device and can be further processed in various ways. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quote

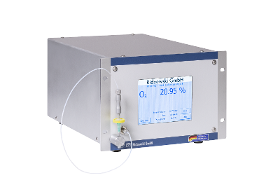

RIDZEWSKI GMBH

Germany

The EPC VM is our measuring device for monitoring O2/CO2 in packaging machines. In addition to continuous measurement of the gas atmosphere, spot measurement of individual packages is also possible. The functionality is the same as with our Zr-Ox EPC spot analyser. Once set, the analyser can also control the gassing of the machine. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels

Request for a quote

REISOPACK S.L.

Spain

Easy to use. The machine can be placed beside the stacked pallet, avoiding the need to move the load. Swappable batteries. - Own manufacturing and technology using highest quality components. - Aluminium head set and tension roller treated ensures long life of the machine. - Tension electronically adjustable through a magnetic clutch to get the strongest tension without any physical effort. - Dual power supply system: To network and with batteries. Removable and interchangeable batteries. - Strapping height manually adjustable without effort. Allows strap from 17 cm. from the floor up to 2 m. - It helps putting edge protectors while first strapping and easy transportation to the place of operation. - Brake lever to prevent unwanted movements. - Bobbin holder located on the base to facilitate bobbin change operation. - Market leader in semiautomatic strapping in fruit and vegetable sector since 1994.

Request for a quote

REISOPACK S.L.

Spain

High performance automatic strapping machine. Very fast. Maximum reliability. - Designed and manufactured using highest quality components. - Aluminium head set and tension roller treated ensures long life of the machine. - Tension electronically adjustable through a magnetic clutch to get the strongest tension without any physical effort. - Electronic control of the tension, heating, cutting and length of the strap. - Adjustment of the cooling after sealing to get better sealing quality, especially for hard packages (wood, iron, etc).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

REISOPACK S.L.

Spain

Automatic horizontal strapping machine with lateral displacement. Ideal option to take a leap in productivity in your business. - Own manufacturing and technology using highest quality components. - Compression system in the arch compacts load and guides the strap to the correct position. - Mechanical tension adjustable through a holding strap system to get the highest tension. - Aluminium head Reisopack 1900 long lasting. - Approximate production higher than 50 pallet per hour. - Security system under the arch with reverse engine. - Touchscreen control 5'6 inch TFT LCD. - Able to store up to 10 different strapping programs. - Automatic corners applicator system.

Request for a quote

REISOPACK S.L.

Spain

Automatic horizontal strapping machine with lateral displacement. Ideal option to take a leap in productivity in your business. - Own manufacturing and technology using highest quality components. - Compression system in the arch compacts load and guides the strap to the correct position. - Mechanical tension adjustable through a holding strap system to get the highest tension. - Aluminium head Reisopack 1900 long lasting. - Approximate production higher than 50 pallet per hour. - Security system under the arch with reverse engine. - Visual signaling errors. - Touchscreen control 5'6 inch TFT LCD. - Able to store up to 10 different strapping programs.

Request for a quote

REISOPACK S.L.

Spain

Automatic horizontal strapping machine with corners applicator system, easy and comfortable to program. Can be integrated into fully automated lines. - Own manufacturing and technology using highest quality components. - Compression system in the arch compacts load and guides the strap to the correct position. - Mechanical tension adjustable through a holding strap system to get the highest tension. - Aluminium head Reisopack 1900 long lasting. - Approximate production higher than 50 pallet per hour. - Security system under the arch with reverse engine. - Visual signaling errors. - Touchscreen control 5'6 inch TFT LCD. - Able to store up to 10 different strapping programs. - Automatic corners applicator system.

Request for a quote

REISOPACK S.L.

Spain

Useful system, simple and easy to program. Suitable for use in fully automated lines. - Own manufacturing and technology using highest quality components. - Compression system in the arch compacts load and guides the strap to the correct position. - Mechanical tension adjustable through a holding strap system to get the highest tension. - Aluminium head Reisopack 1900 long lasting. - Approximate production higher than 60 pallet per hour. - Security system under the arch with reverse engine. - Visual signaling errors. - Touchscreen control 5'6 inch TFT LCD. - Able to store up to 10 different strapping programs. - Can be integrated into a fully automated line.

Request for a quote

PACKFEEDER

Spain

Either due to the container having handles, serigraphs or simply geometries that make it asymmetrical, the Packfeeder modules provide fast and effective solution to the feeding requirements. The main benefits of the Packfeeder orientation system are: - Simple and efficient operation. - Little additional space required, keeping the feeding and unscrambling of packages unit very compact. - Great ergonomics in its use and maintenance thanks to the modularity in line concept. - Ability to feed packages on a belt or inserted into pucks. - Proven effectiveness in any asymmetric geometry that requires feeding.

Request for a quote

PACKFEEDER

Spain

This module adapts the Packfeeder feeder to a packaging line that uses pucks to transport products. The main benefits of the Packfeeder puck system are: - Easy-to-operate and efficient design. - Little additional space is required, ensuring that the puck feeder assembly stays extremely compact. - Outstanding ergonomics during use and maintenance thanks to the in-line modularity concept. - It is the simplest puck loading system on the market. - Works with both closed and open pucks in any shape and size. - Guarantees that 100% of the pucks are full after passing through the feeder with no additional sensors needed. - System adaptable to existing puck production lines.

Request for a quote

PACKING TECHNOLOGIES LLC

Ukraine

Power, Wt/Hz – 220/50 Installed capacity, кW – 1,5 Pneumatic Supply, atm./l.m. – 250/4 Dimensions (not more than), mm – 1800/900/1100 Weight ( not more than ), kg - 250 Packaging dimensions, mm – 50-150/50-150 Output (max), packs per hour - 2 000

Request for a quote

PACKING TECHNOLOGIES LLC

Ukraine

Voltage, V/Hz – 220/50 Installed power, кW – 1,5 Pneumatic Supply, atm./l.m. – 150/4 Dimensions (not more than), mm – 2200/900/700 Weight ( not more than ), kg - 210 Packaging dimensions, mm – 20-150/17-50 Output (max), packs per hour - 12 000

Request for a quote

MAKOSAN MAKINA

Turkey

Flow Pack Packaging Machine Quatro - 300 - 2S .B

Request for a quote

FERPLAST SNC

Italy

PRATIKA 55 SMART: AUTOMATIC THERMORETRAIBLE PACKAGING MACHINE WITH INCORPORATED TUNNEL The new model of automatic shrink-wrapping machine Pratika 55 Smart comes from a careful attention to the needs, with the aim of offering a technologically advanced but flexible and extremely compact product. The included tunnel, revolutionary in the world of automatic machines, responds to the needs of space, but above all to reduce the labor costs to a minimum, thanks to the patented "come back" option to a single operator. Enhanced by a strong mechanical and electronic technological content, the new Pratika 55 Smart represents a perfect synthesis of reliability, versatility and safety, which once again evolves the way to conceive the compact automatic operation shrinkwrappers.

Request for a quote

FERPLAST SNC

Italy

BSL 5045 SEMIAUTOMATIC ANGULAR PACKAGING MACHINES Angular packaging machines with manual or automatic closing of the sealing bar and motorized product unloading belt. They can be combined with a retraction tunnel. FEATURES: - Sealing blade in NI-CR with non-stick coating - Control of the welding time to avoid overheating - Conveyor belt adjustable in height by handwheel - Double magnet for high closing force - Reel holder sliding on ball bearing guides, useful width mm. 550 - Return of the sealing bar controlled by a gas spring (for the 5045 L manual version) - Pneumatic device (compressed air) for closing and opening the sealing bar (for the BSL 5045 LA semi-automatic version) The BSL 5045 LA model is equipped with a maintained action dual control (the two buttons must be held down until the bars are completely closed).

Request for a quoteResults for

Packaging machine - Import exportNumber of results

236 ProductsCountries

Company type

Category

- Packing and packaging - machinery and equipment (56)

- Food industry packaging machinery (30)

- Food packaging (25)

- Paper and cardboard manufacturing - machinery and equipment (15)

- Wrapping machines (14)

- Packaging (12)

- Food industry - machinery and equipment (10)

- Hats and caps (8)

- Bag filling machinery and equipment (7)

- Metal packaging machine (7)

- Sealing and wrapping - machinery and equipment (7)

- Strapping, metal (7)

- Bakery and confectionery industry - machinery and equipment (6)

- Food Industry - Machines & Equipment (5)

- Package sealing machinery (5)

- Cartoning machinery (4)

- Cosmetics industry - machinery and equipment (3)

- Plastic packaging (3)

- Custom packaging (2)

- Anti-corrosion products, chemical (2)