- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- planetary mixers

Results for

Planetary mixers - Import export

UMMANMAK

Turkey

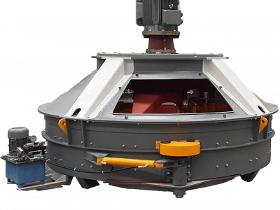

High Homogeneity is indispensable for the quality of concrete. One of the most successful of different types of concrete mixers is planetary mixers. Our Planetary Mixer Model with Capacity Varying Between 0.5 m³ and 1 m³; It is the type of mixer whose drive is above the mixer. It is preferred according to the design and cost of the concrete plant. In addition to having high performance, it has a stylish and aesthetic appearance. It is easy to use and clean. It complies with CE standards.

Request for a quote

ELKON GMBH

Germany

ELKON planetary mixers are designed to perform high mixing performance even for the challenging applications and mostly preferred for producing precast concrete products such as low or zero slump precast concrete, fiber reinforced concrete, self-compacting concrete, etc. They provide the highest homogeneous mixture even in shorter mixing time as the mixer turret is rotating around the mixer center point and in the meantime mixing stars connected to this turret are circumvolving. Advanced Features of ELKON Planetary Mixers High mixing performance even for challenging concrete applications High mixture homogeneity in shorter mixing time High wear-resistant mixer wearing parts Easy maintenance due to wide maintenance gates and bolted type replaceable linings Italian gearbox (COBRA) Low maintenance cost

Request for a quote

ECSMT MACHINERY EQUIPMENTS

Turkey

The planetary flap is featured with traditional design and faster mixing speed. The valve and liner plate are made of wear-resistant high chrome alloy material and have a long service life. It has more blades than the design of other models. Blades and liners are made of high chrome wear-resistant materials with long operating life. Models with 1m3 and above are multiple-motors, thanks to this feature, it provides 30% more efficient and faster production than its equivalents.

Request for a quote

DIRMAK MAKINA SAN. TIC. LTD. ŞTI.

Turkey

We are producer of Planetary mixers from 10 L to 300 L. Main Specifications are floor model or bridge type model which are suitable for all kneading, mixing and whipping operations.Body painted with corrosion resistant electrostatical paint or AISI 304 stainless steel option. Powerful asynchronous motor with electronical speed variator. Water protected planetary system. Stainless steel bowl guard. Water proof button control panel with 60 minutes timer. Bowl position device allows the mixer to switch on only when the bowl and safety cover are properly positioned together.

Request for a quote

ELKON GMBH

Germany

"This is the most preferred model of ELKON Mobile Master Series in terms of capacity.In addition to the different mixer types such as 1500/1000 l. pan, planetary or twin shaft mixer, the integrated build-in 36 ton cement silo is also available upon request to reach the highest mobility. Production capacity of ELKON Mobile Master-60 Mobile Concrete Batching Plant is 50 m³/h. It provides the following advantages to its users - Quick and easy installation (only 1 day) - Cost-effective transportation (the main unit can be transported by one truck trailer) - Maximum mobility with 36 tons capacity integrated cement silo (only for Bear model) - Due to the special design, it can be installed on a confined space - Quick and easy jobsite relocation

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELKON GMBH

Germany

ELKON stationary concrete batching plants are being manufactured since 1980’s. The lowest capacity one in this series is ELKOMIX-60 Stationary Concrete Batching Plant, depending on the application, can be equipped with 1500/1000 l. pan, twin shaft or planetary mixer. Moreover, it can also be manufactured without mixer for dry type concrete production. ELKOMIX-60 Stationary Concrete Batching Plant which has 60 m³/h concrete production capacity is the product of ELKON’s high quality and advanced technology and provides the following advantages to its users - Flexibility in the configuration - High production performance and high productivity - Easy installation due to its modular structure - Variable layout options - Wide operating and maintenance areas - Easy maintenance and low operating costs

Request for a quote

MRM CONCRETE BATCHING PLANTS

Turkey

It is designed for easy and fast installation, economical shipping and high capacity operation. We have never designed anything we produce just to look good. It would be to misjudge an opportunity that has come our way. Instead, we reconsidered the concept of “Optimum Power Plant” and while designing a more efficient and more economical power plant, we did not forget the needs of our customers.

Request for a quote

SICOMA OMG LTD

United Kingdom

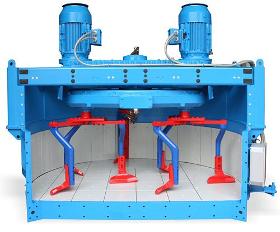

Planetary mixers are the industry standard for the most efficient mixing of all grades of concrete. The three blade ‘egg whisk’ mixing action on each head gives complete coverage of the entire floor of the mixing pan. The blades rotate on an ever-changing axis, as the gearbox spins the blade carrying spider. What makes Sicoma OMG mixers the best? - Range of sizes from50 – 4000 cu litres - Fast and thorough mixes for all types of dry-cast concrete - No dead spots - 30 second mixing time for most concrete mixes - Greater consistency, higher output and stronger mix - Fast and complete discharge - Hard wearing NI-Hard cast-iron liner plates for floors and walls - Optional internal high-pressure washer system to reduce clean-out time - Gearboxes manufactured in-house, double horizontal design is strong and shock resistant, with a horizontal oil bath to give every gear optimum lubrication and cool running. ** Click to read more **

Request for a quoteResults for

Planetary mixers - Import exportNumber of results

9 ProductsCountries

Company type