- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- roller transport

Results for

Roller transport - Import export

BRUNO UNGER GMBH & CO KG

Germany

Nip rings, transport rollers, cutting rings, with and without coating

Request for a quote

NERI MAKINA MÜHENDISLIK SANAYI VE TICARET LTD. ŞTI.

Turkey

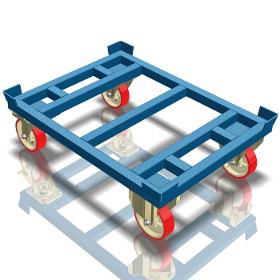

Pallet dolly (Tugger trains) have a robust welded steel construction and are equipped with 4 catch corners. The surface of the trolleys is galvanized or powder-coated, has permanent surface protection and is impact and scratch resistant Swivel and fixed castors: polyurethane tires, hubs with deep groove ball bearings, brakes on the swivel castors, in accordance with the European standard EN 1757-3. Housing galvanized. Standard wheels for medium loads. Quiet running, spring-loaded drawbar.

Request for a quote

PARSMEGA MAKINA

Turkey

It enables the broken and crushed product in the rollers to be transported to the sieve and other machines. It absorbs the broken or crushed product through steel pipes and distributes it to cyclones and ecluses. Consists of outer body and fan part. The outer body has a snail structure. The internal fan is designed with paddles according to capacity. It is mounted coupled to the engine located on the outer body. The fan inside the body rotates at high speed and provides air suction and pressure. Since the fan is specially balanced, it does not cause vibration or noise. In addition, since the outer body is placed on the main chassis on special rubber wedges, it does not cause vibration on the chassis.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

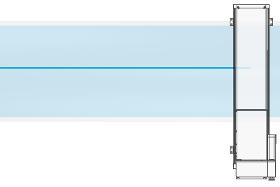

The transfer vehicle is used for transporting cargo horizontally on a single level. The individual loading units are moved on and off the racking by interconnecting the integrated roller conveyor with external roller decks. As well as transporting ULDs which take up the entire surface of the roller deck, it is possible to transfer two containers simultaneously. Flow plane: Horizontal Flow direction: Unidirectional Functions: Transporting, storing and retrieving ULDs Operating modes: Fully automated, semi-automated, maintenance Benefits: A safe way to transport ULDs with care IATA-compliant transportation of ULDs

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

The roller deck is used to transport ULDs and pallets in a single direction on a horizontal plane and is combined with other elements to create an overall system. Flow plane: Horizontal Flow direction: Unidirectional Functions: Buffering and transporting ULDs Operating modes: Manual and powered Feature: Non-slip walkways between the rollers

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Powerful derinding machine for large and small pieces of cheese. In addition to an ideal cutting width, the Weber Cheese Skinner offers product-specific height adjustment of the blade, meaning that natural and plastic rinds can be optimally removed. Maximum product yield is guaranteed. Advantages Powerful and with a compact footprint A special cheese transport roller and perfectly adjusted blades for optimal processing results Ideal cutting width for powerful derinding of large and small pieces of cheese Bolted blade with blade protection in cleaning position Unique geared brake motor with quick stop Options: special voltages

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

Fast, safe, reliable, economical. This is what distinguishes our standard and flat lift platforms. High quality and availability of LAWECO lift platforms are only two reasons why your investment will always pay off long term. In addition, LAWECO offers particularly high safety standards which, in this form, cannot be taken for granted.

Request for a quote

NORELEM FRANCE

France

Bearing flanges and fastening pieces PAGF. Bolts steel. Black. Bolts electro zincplated. Two bearing flanges combined with a D50 type I aluminium profile tube (10050) form a feed roller (loadbearing roller). The bearing flanges are simply pressed into the aluminium profile tube. These can be used for many conveyance tasks. The bearing flanges have ball bearings and springloaded fastening spigots which enable transport rollers to be retrofitted into existing structures. A roller conveyor is created when several transport rollers are mounted in series. Two bearing flanges are required for a transport roller.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of slow-running rolling and friction bearings, rollers, transport chains or sliding surfaces on kiln trolleys, bakery machines, drying tunnels, foundry machines, boiler firing systems, plastics processing machines for welding and soldering machines etc. Advantages and benefits Highly effective due to optimum temperature-stable silicone grease formula Excellently suited for grease lubricating points subject to high-temperature loading Broad range of uses outside normal grease performance areas

Request for a quote

MICRO-EPSILON

Germany

The thicknessGAUGE O.IMS is used for stable thickness measurement of coating on separator film. The system is designed as a compact O-frame and uses a white light interferometer that traverses over the battery film. Thanks to the innovative technology, the thickness measurement is contactless from only one side. Two transport rollers stabilize the film belt.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

One for many purposes: Powerful skinning machine for large and small cuts of beef, veal, pork, turkey, horse and game. The Skinner AMS 533 offers an ideal cutting width for processing large cuts, such as beef topside. Advantages Powerful for the highest yield from the smallest installation area Product-specific optional transport rollers and speciallycoordinated blades provide the highest possible yield Ideal cutting width for powerful skinning of large and small cuts Blade guard in cleaning position Gear brake motor with quick stop Product-specific tension rollers Newly-developed compressed air transport roller cleaning,resulting in consistent skinning results Options: Body lever switch Quick release lock for tool-free blade changes Special rollers Skinning procedure protection Special tension rollers

Request for a quote

GSW SCHWABE AG

Germany

with counterweight secure pick up and transportation of coils, rollers, rings, bushings an so forth easy handling through counterweight balance safety nib available on request without additional charge

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Combination machine for thick and thin: The AMS 533 TWIN skinning machine is particularly suited to processing cuts with thick tendonsand skin, such as pork loin, pork silverside, beef or veal silverside and boiled beef fillet. Advantages Removal of tendons and skin with one machine TWIN transport rollers and specially coordinated blades providethe highest possible yields Ideal cutting width for powerful skinning and tendon removal inlarge and small cuts Effort-saving work table design due to ergonomicmachine assembly Blade guard in cleaning position Gear brake motor with quick stop Product-specific precision adjustment Options: Quick-clamp blade holder for tool-less blade changing Body lever switch Skinning procedure protection Skinning gloves Special tension rollers

Request for a quote

GSW SCHWABE AG

Germany

with its compact design using a structural aluminum profile, conveyor system is ideally suited for continuous duty applications in multiple shift environments. using the benefits of modular construction, this conveyor can be readily integrated into new or existing equipment or be used as a freestanding conveyor for bulk handling and loading aplpications. inclination smoothly adjustable steplessly fourwheel drive, 2 steering wheels with parking brake 13 collector rollers, height 20 mm transport cover PUeven, 2 layers, to be used at temperatures from 30 120°C, oiland grease resistant, antistatic funnel (attachment), aluminium anodized drop area pivotable clip/aluminiumclosed bar system suitable for materials to be conveyed from a thickness of 2 mm on for lower thicknesses of materials to be conveyed, allaround corrugated material edges made from celloflex. This reduces the usable width of the material by approx. 70 mm

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The smart solution: Fully-automatic defatting machine ASD 460 enables removal of fat layers from loins and cutlets in predefined strengths. Advantages Fully-automatic recognition of the fat strength using Weber camera technology, with programmable controlled movementalong longitudinal profile Continuous work process Sensor-controlled electronic spring for perfect pressure application Uniform fat layers Considerable minimisation of reworking (trimming) Back bacon instead of small trimming cuts Clearly improved product image for cooking after slicing Product-specific blade holders Combinable with pre-installed derinder Options: Special Weber transport rollers Product-specific blade holders Product-specific pressure devices for products withand without bones Fixed or adjustable guide plates for supply and output belts

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication of most different materials sliding on resp. rubbing against each other like metals, wood, ceramics, rubber as well as paintable plastics For packing machines, sliding areas in the plastics and textile industry, rollers and chutes in the transport range, etc. Non-stick coating of all kinds of sealings and sealing areas to avoid sticking, squeaking of soft on hard materials (e.g. rubber on glass), for water-repellent impregnation of absorbing materials or as separating film for casting resin applications Advantages and benefits Thin, tack-free separating film with very good adhesive properties on prepared surfaces Best suitability for low-friction lubrication of all kind of materials in contact Colourless and odour-free antifriction coating with non-stick properties

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Up to 11000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for10.000pcs/hour) 6 pocket stainless steel dough carrier tray 278 pieces active tray 1668 active pockets Removable and washable UHMWPE mesh pockets 2″roller chain for tray transport Main frame is stainless steel tube. Total power 1.5 kW.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 7000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 4 pieces 50mm diameter pistons Changable outer drum for different weights 4 rows outlet belts. Automatic oil lubrication Variable speed controlsfor main drive and rounding unit Flour duster Dough bunker capacity is 140 kg Safety switches on doors Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 4000pcs/hour) 4 pockets stainless steel dough carrier tray 146 pieces active tray 584 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chain for tray transport Main frame is stainless steel tube Total power 1.1 kW Easy Access for maintenance Safety switches on doors

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Full power in any position The universal machines from BEHRINGER can handle any job that is needed. Perfect to slicing through sectional steel as well as solids in metal and comparable plastics at almost any optional angle. With precise cuts, individually adjustable for bidirectional mitre cuts between 90° and 45°, and optionally even for acute angles of 30°. Semi-automatic variants In the BEHRINGER semi-automatic models, the material is positioned by eye, for instance with the aid of a linelaser. This procedure is recommended for frequently changing cut-off length and when the sections are marked on the material already. Automation Where larger cut-off lengths are required, we recommend the use of a measurement device for precise positioning of the material. Used in conjunction with infeed and outfeed peripheral devices such as roller conveyors and transverse transport devices, the degree of automation can be increased to achieve added streamlining effects.

Request for a quote

MOSCA GMBH

Germany

• SoniXs Ultrasonic sealing unit in standard-6 version • 4 swivel castors, 2 of them are lockable • Strap end detection with ejection of remaining strap • Easy accessibility and tool-free dismantling of strap path components • Easy operation over digital display in the control panel • CE marking inclusive conformity declaration • Extremely low energy consumption [MC] • Flexible foot pedal for manual strap release • Tool-free dismantling of the table plate [TRC] • Potential-free contacts to upstream and downstream machines • Selector switch for single, double or multiple strapping • Infinitely adjustable conveyor speed from 0.1 to 1.0 m/s • Optimization of the strapping processes by machine adaptation to defined package dimensions • Electromechanically driven aluminium rollers ensure an optimal product transport • Tool-free dismantling of roller system • Pneumatic hold-down device with manual prepositioning • Bundle positioning via time

Request for a quote

MOSCA GMBH

Germany

Ultrasonic sealing system with electronic self-calibration High-end Standard 6 sealing unit Dispenser variably mountable Intuitive user guidance via colored touch panel Electromechanically driven aluminum rollers ensure an optimal product transport Continuously adjustable conveyor speed from 0.2to 1.0m/s Bundle positioning via increments by metrical input of the strapping positions Open design without protective coverings - CE marking inclusive conformity declaration Infeed side guidance Extremely low energy consumption

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

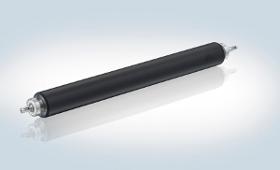

The smallest needle rollers transport veneers in edge banding machines. Our largest needle rollers are over 4 meters long and can only be shown here in cut-out.

Request for a quote

UNIL LUBRICANTS

Belgium

Grease HT 300 is a grease based on bentone, suitable for use at very high temperatures with peaks up to 250°C. Due to the unique additive package, this grease is remarkably resistant to high pressure, which offers protection under heavy loads. Benefits For use on all machines (except fast-moving bearings) under high temperatures (with peaks up to 250°C), such as in drying furnaces and ovens, transport chain rollers, … Excellent adhesive properties. Not soluble in water.

Request for a quote

PROXOMED® MEDIZINTECHNIK GMBH

Germany

Technical data Dimensions (L/W/H) 210/80/136 cm Total weight 200 kg kardiomed Reha Mill S Item no. 10081300 Incline angle 0 to 25% (0 to 14°) , integrated chipcard system kardiomed Reha Mill S Item no. 10036900 Incline angle 0 to 25% (0 to 14°) Equipment Integrated chip card system Safety stop Running surface 150 x 50 cm Step height 16 cm Incline angle 0 to 24% (0 to 13.5°) Transport rollers 3 to 131 sec. (from 0 to max.) Training programmes Quick start, time training, pulse training, calorie training, hill training, random training, interval training, distance training Options Polar Sender Set T 31, uncoded Polar Sender Set, T 31, coded proxotrain software + IPN Test Suite

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

Transport and drive rollers must provide precise transport of the print media in the digital printing process. This is especially true for wide format inkjet printers. Tracking lines, artifacts on the printout, or paper feeding failures are not accepted by the end-user. Our transport rollers are subject to the highest quality standards in respect to: Perfect, defect-free surfaces Precisely defined surface roughness High friction stability over life Tight tolerances in all dimensions

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The boards to be coated are fed to the raw-board-handling section where they are separated to allow their surfaces to be cleaned. Features, function A forklift truck is used to place the board stacks on to a roller table from where roller conveyors or horizontal transfer carriages equipped with roller conveyors transport them to one of the two separating station's places. A suction carriage removes the top board from the stack and places it on a conveyor that takes it to the surface-cleaning machine. Advantages The two redundant stacking places allow the short-cycle press to be supplied without interruption. They make it possible to feed new stacks of boards without the need to shut the machine down

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

DAMBACH roller conveyors consist of a stable frame with rollers bolted in place. The rollers are driven by an easily serviced tangential chain drive with tensioning unit housed in a drive enclosure. The entire drivetrain is enclosed for safety and to prevent tampering. Flanged wheels rotate with the rollers to help transport goods carefully. The frame is height-adjustable. DAMBACH chain conveyors consist of self-supporting chain strands mounted on a rigid frame. The number of strands can be varied to suit the application. Duplex chains with straight side plates guarantee careful transport of your goods on an optimised support surface. Chains are supported on low-friction slide rails and can be individually tensioned. All chain strands are driven via a common driveshaft fully enclosed for safety. The mounting frames bolted to the main frames are height-adjustable. High throughput rates Travelling speed up to 0.5 m/s and acceleration up to 0.8 m/s² Max. 1500 kg per storage position

Request for a quoteResults for

Roller transport - Import exportNumber of results

43 ProductsCompany type

Category

- Bakery and confectionery industry - machinery and equipment (3)

- Meat processing machines (3)

- Goods handling systems, continuous (2)

- Machine tools, metal shaping - parts and accessories (2)

- Packing and packaging - machinery and equipment (2)

- Palletising machinery (2)

- Silicones (2)

- Carpentry - machinery and equipment (1)

- Connectors, pneumatic (1)

- Conveyor systems (1)

- Food Industry - Machines & Equipment (1)

- Mechanical transmission systems and components (1)

- Oils, cooking - machinery and equipment (1)

- Printing - supplies (1)

- Rotogravure (1)

- Sandblasting equipment (1)

- Sawing machine tools (1)

- Sensors (1)

- Sterilisation and disinfection - medical equipment (1)

- Storage equipment and systems (1)