- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless-steel strip

Results for

Stainless-steel strip - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Standard: ASTM, AISI, DIN, EN, GB, JIS, SUS Length: as your request Width: 1000-1280mm Place of Origin: China Type: CoilCircle,Sheet Application: Construction., Bending, Shaping, Drawing Certification: ISO Processing Service: Cutting Technical Treatment: Cold Rolled Surface: BA, 2B, 2D, HL, #4, SB Edge: Mill-Edge or Slit-Edge Tolerance: ±0.02mm Supply Ability: 10000 Metric Ton/Metric Tons per Month 410 stainless steel Packaging Details: Standard export packing Lead time: 15-30days Payment term: T/T,L/C etc. Port of shippment: Xiamen,China

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Precision re-rolled stainless steel strip products can be engineered to specific customer requirements with exceptionally short lead times. Based on our longstanding expertise, we can manufacture stainless steel strip to precise custom sizes, ultra-thin gauges and tightly controlled mechanical properties with any surface finish. We also work closely with Hamilton Precision Metals, part of AMETEK Specialty Metal Products, to produce stainless steel foils down to 1.5 microns (.000060”) thickness. Standard Alloys We manufacture stainless steel strip in a variety of chemical and mechanical properties, expertly engineered to your exacting specifications. High performance stainless steel strip material includes: Austenitic: 300 series Martensitic: 400 series Ferritic: 400 series PH Grades 17-7PH®, 17-4PH® Additional options available on request

Request for a quote

STAINLESS BAND LTD

United Kingdom

Our aluminium boxed banding is available from stock in widths from 12.70mm (1/2”) to 25.00mm (1”) wide and thickness 0.30mm (0.012”) to 0.50mm (0.020”) Standard grade 1050 HH other grades are available at request. Coils can be supplied as standard 2kg rolls or as boxed banding with safe edges. Supplied on wooden pallets and shrink-wrapped. Maximum pallet weight 1500kg. A full export service is available for worldwide supply. Aluminium wing seals in 12.70mm (1/2”), 19.05mm (3/4”) and 25.00mm (1”) sizes are also available, and are compatible with aluminium or stainless steel banding. Certificates of conformity, showing the exact chemical composition of the material are supplied with each delivery.

Request for a quote

STAINLESS BAND LTD

United Kingdom

At Stainless Band we have the capacity to polish material in coil form or blanks in various grades including AISI 304-S15- 1.4301 EN 10088-2/ASTM A240. We can offer the following finishes from 120 to 320 Grit as well as standard 2B or BA finished. Material can be made into blanks with lengths from 100mm to 3000mm long. Standard thicknesses 0.10ms from m - 4.00. and widths from 2.50mm to 1500mm maximum. Our standard tolerance is EN ISO 9445:2006 but others are available. We can provide coating films, PE and PVC surface protection. Finishes can range from smooth and slightly reflective through course, medium, fine and bright and reflective.

Request for a quote

STAINLESS BAND LTD

United Kingdom

Customers who use narrow width strip can increase productivity with oscillated wound coils as large as 1000kgs. The benefit of this larger wound coil is that the coil needs to be changed less frequently and therefore reduces downtime. Common uses for oscillated wound is the building industry and automotive sector, this process has been proven to increase machine output by 40% on pressing lines. Our oscillating wound is available in thicknesses 0.40-3.00mm with a width to 3.00-80mm. With a coil weight of 100kgs or coil OD 1,000,00mm and pack width optional 200/350mm. Our stainless steel oscillating wound is WAK edge dressed on wooden spools. The inside diameter is 406, 508 flash butt welding method with reannealing. The welding method is 90 degree TIG-skew tolling, seam smoothened. Marking is in accordance to client specification.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Quality First, Customer Satisfaction are our goal

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Stainless Steel Foil is the most widely used decorative materials

Request for a quote

WUS WILHELM UNGEHEUER SÖHNE GMBH

Germany

Gutter supports, semi - circular and box section, dimensions 200 mm / 25x5 up to 500 mm / 30x8 3.6" / 0.98"x0.2" up to 10" / 1.18"x0.31" Some versions available with Stainless Steel metal strips, short and long Available surfaces: Hot dip galvanized Galvanized and powder - coated Solid copper We would be very pleased to support you with all your individual questions and suggestions regarding WUS. Give us a ring or leave a message indicating the information you need. We will contact you as quickly as possible. Your WUS team

Request for a quote

WUS WILHELM UNGEHEUER SÖHNE GMBH

Germany

Gutter supports, semi - circular and box section, dimensions 200 mm / 25x4 up to 500 mm / 40x5 3.6" / 0.98"x0.16" up to 10" / 1.57"x0.2" Short version available with 2 metal strips or one metal strip and one nozzle Version with 2 metal strips can be equipped with stainless steel metal strips or in longer version Available surfaces: Hot dip galvanized Galvanized and powder - coated Solid copper Stainless Steel AlSI 304 (1.4301) We would be very pleased to support you with all your individual questions and suggestions regarding WUS. Give us a ring or leave a message indicating the information you need. We will contact you as quickly as possible. Your WUS team

Request for a quote

BILLI DICHTUNGSTECHNIK GMBH

Germany

In order to be able to meet the individual requirements of our customers, we offer various types of spiral wound gaskets: For example, you can choose between standard versions with a smooth surface and various special models. All articles are based on a stainless steel strip and high-quality filling materials such as graphite and PTFE, which underlines the excellent quality standard. The spiral wound gaskets of billi are characterized by a constant elasticity during hot-cold cycles. Classical applications in the chemical industry include all types of gas lines, directional valves and pumps. Furthermore, spiral wound gaskets are the optimal solutions for pressure vessel openings in steam systems as well as low and high pressure in nuclear power plants. For the best possible functionality of spiral wound gaskets, the careful considered choice of model is of central importance: the versions with centering ring, for example, assures an ideal fit between the bolts.

Request for a quote

FLEXOMAT GMBH

Germany

The term metal bellows refers to a structure that is composed of one or more stainless steel sleeves fitted into one another and is rendered elastic by the introduction of parallel corrugations. Metal bellows can be arranged to complete combinations of metal bellows (expansion joints). Thus, every specific requirement can be met. As raw material for the sleeve production, stainless steel strips or sheets with a thickness of 0.15 - 3 mm in the standard grades are used: 1.4541 / AISI 321 1.4571 / AISI 316Ti 1.4404 / AISI 316L 1.4307 / AISI 304L material with high chemical resistance and temperature resistance: 1.4435 / AISI 316L 1.4539 / AL 904L 1.4878 / AISI 321H 1.4828 / AISI 309 1.4462 / AISI 318 LN 1.4410 / AISI F53 or additional special materials: 1.4876 / Incoloy 800HT 2.4858 / Incoloy 825 2.4856 / Inconel 625 2.4816 / Inconel 600 2.4610 / Hastelloy C-4 2.4819 / Hastelloy C-276 2.4602 / Hastelloy C-22 3.7035 / Tit

Request for a quote

FLEXOMAT GMBH

Germany

The term metal bellows refers to a structure that is composed of one or more stainless steel sleeves fitted into one another and is rendered elastic by the introduction of parallel corrugations. Metal bellows can be arranged to complete combinations of metal bellows (expansion joints). Thus, every specific requirement can be met. As raw material for the sleeve production, stainless steel strips or sheets with a thickness of 0.15 - 3 mm in the standard grades are used: 1.4541 / AISI 321 1.4571 / AISI 316Ti 1.4404 / AISI 316L 1.4307 / AISI 304L material with high chemical resistance and temperature resistance: 1.4435 / AISI 316L 1.4539 / AL 904L 1.4878 / AISI 321H 1.4828 / AISI 309 1.4462 / AISI 318 LN 1.4410 / AISI F53 or additional special materials: 1.4876 / Incoloy 800HT 2.4858 / Incoloy 825 2.4856 / Inconel 625 2.4816 / Inconel 600 2.4610 / Hastelloy C-4 2.4819 / Hastelloy C-276 2.4602 / Hastelloy C-22 3.7035 / Tit

Request for a quote

FLEXOMAT GMBH

Germany

The term metal bellows refers to a structure that is composed of one or more stainless steel sleeves fitted into one another and is rendered elastic by the introduction of parallel corrugations. Metal bellows can be arranged to complete combinations of metal bellows (expansion joints). Thus, every specific requirement can be met. As raw material for the sleeve production, stainless steel strips or sheets with a thickness of 0.15 - 3 mm in the standard grades are used: 1.4541 / AISI 321 1.4571 / AISI 316Ti 1.4404 / AISI 316L 1.4307 / AISI 304L material with high chemical resistance and temperature resistance: 1.4435 / AISI 316L 1.4539 / AL 904L 1.4878 / AISI 321H 1.4828 / AISI 309 1.4462 / AISI 318 LN 1.4410 / AISI F53 or additional special materials: 1.4876 / Incoloy 800HT 2.4858 / Incoloy 825 2.4856 / Inconel 625 2.4816 / Inconel 600 2.4610 / Hastelloy C-4 2.4819 / Hastelloy C-276 2.4602 / Hastelloy C-22 3.7035 / Tit

Request for a quote

KULLEN-KOTI GMBH

Germany

Kullen-Koti roller brushes 302 are indeed unique and easy-to-handle: you only purchase the roller brush core once and easily refill it yourself with the corresponding strip brushes after wear. And besides, it is a very economical brush system. The ruged construction allows problem-free operation also in adverse conditions. Roller brushes type 302 consit of a tubular steel or stainless steel core and exchangeable strip brushes which are mounted in axial direction around the circumference. The brush core can be supplied either with journals or with arbor hole for mounting on the existing primary shaft. With the roller brush type 302 (mS) the strip brushes are fixed in side flanges. With type 302 (oS) the strip brushes are fixed directly on the tubular core with clamping plates. Fill configuration to choose: bent in axial direction, left-hand or right-hand pitch or in chevron pattern i. e. left hand and right-hand pitch starting at the centre. Strip brushes needed around the...

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Our stainless steel filaments are available in Grades 316 & 304, in many diameters and crimp.....

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Stainless steel backing strip can be filled in any materials: Polymers, wire, natural fibres, rubber, rubber inserts, animal hair or any mixtures of these products. They are available in 5mm, 8mm & 10mm stainless steel backing strip with filament lengths to suit the application. 3mtr lengths only. Aluminium or stainless steel holders are available.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ILK IHRACAT AS.

Turkey

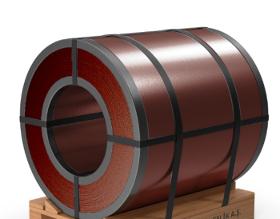

Zinc-coated galvanized sheets are transformed into painted sheets with various color options through a special surface painting process. Products offered in colors such as RAL9002, RAL3009, RAL7016 are coated with protective film and topcoat paint to achieve a perfect appearance. Technology and Durability Together: The steel sheet surface is reinforced with primer paint and PET film coating processes. The thick PVC-based topcoat offers high flexibility, scratch resistance and styling properties. Plastisol can be safely used indoors and outdoors in roofing, cladding and gutter systems. Areas of Use: Pre-painted sheets are preferred in many sectors from furniture to construction. It combines aesthetics and durability by being used in roll, sheet, trapezoidal, corrugated and embossed shapes. Aesthetics and Protection: Various colors of PPGI add an aesthetic touch to your projects. It also offers a long-lasting and durable material thanks to its zinc coating and protective film.

Request for a quote

EVTERPA COSMETIC & CO LTD

Bulgaria

Men's razor with 3 blades and 1 moisturizing strip - For a comfortable, precise and safe shave with sensitive skin. 3 pieces of fine blades made of stainless steel. Moisturizing strip for easy shaving without the risk of injury and irritation. Ergonomic handle with special coating for a stable grip.

Request for a quote

FATH GMBH

Germany

Handles in various designs and dimensions: — ergonomic design and finger protection — electrostatically discharging — with/without bore and cover caps Front handle, handle, bridge handle, machine handle, comfort handle Material selection: — Plastic PA glass fibre reinforced, black — Plastic PA glass-ball reinforced, black System handle Material selection end piedes: — Plastic PA glass-ball reinforced, black Material selection tubes: — Carbon fibre, glossy finish — Aluminium, anodised — stainless steel — Steel plastik covered Strip handle Material selection handle strip: — Aluminium Material selection cover caps: — PA glass-fibre reinforced plastic Other sizes, other colors on request

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

S20910 stainless steel provides a combination of good corrosion resistance and strength not found in any other commercial material available in its price range. This austenitic stainless steel has corrosion resistance greater than that provided by types 316 and 316L, plus approximately twice the yield strength at room temperature in the annealed condition. In addition S20910 stainless steel has very good mechanical properties at both elevated and sub-zero temperatures a well as outstanding cryogenic properties. And, unlike many austenitic stainless steels, 22-13-5 stainless steel can be heavily cold worked to enhance its yield strength and remain non-magnetic. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM® 455 is a precipitation heat treatable martensitic Stainless Steel. The composition provides a good combination of corrosion resistance and heat treated strength favorable for fatigue applications. The material is well suited for demanding spring devices The alloy has reasonably good forming characteristics in the annealed temper considering that it has a hardness of RC30. A significant radius is useful when bending is necessary in a fabrication. Cold working prior to the precipitation hardening treatment can drive finish strength up to 270,000 PSI (0.2% offset yield strength). The alloy retains a good strength through 800°F (Approx. 70% of room temperature). Resistance to stress – corrosion cracking is optimized by heat treating at 950°F. The overall corrosion resistant to normal atmospheric is equal to SS 430 with no staining. The alloy can be welded by resistance and inert gas shielded techniques. It also is suitable for brazing using a flux when possible.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 17/4 PH® is a precipitation hardenable Martensitic stainless steel with high strength, and good corrosion resistance. This makes it perfect for use in metal diaphragms, for both aerospace sensors and burst discs. It is easily heat treated from the annealed temper. The corrosion resistance of the alloy is comparable to SS 302. It is heat treated at 900° F/1 Hour for highest strength. Other thermal treatments can be utilized to provide greater toughness and improved formability. Joining of the alloy is accomplished by the usual methods that are effective for stainless steel. Available Sizes: SS 17/4 PH® is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.050” (0.0254 mm to 1.27 mm) and widths up to 12.0” (304.8 mm). The material conforms to AMS 5604, ASTM A693 and UNS S17400.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 301 is an austenitic Chromium-Nickel stainless steel capable of attaining high strength with moderate cold working. The combination of high strength and good ductility makes it suitable for numerous mechanical switches as well as surgical instruments, metal stampings and electronic and computer spring components.. The alloy is readily formed in the annealed temper. Ductility decreases with increased cold rolled strength but not to the degree that would occur with SS 302. It is not recommended for deep drawing. SS 301 can be welded by all conventional processed except oxy-acetylene. The weld should not make contact with electrolytes to prevent intergranular corrosion. SS 301 is resistant to atmospheric corrosion and is additionally resistant to mildly corrosive mediums. The combination of narrow strength bands and close thickness tolerance provided by Hamilton Precision Metals is the key to repeatable response characteristic in spring and switch applications.

Request for a quote

3AS STAINLESS STEEL C.J.S.C.

Turkey

-COILS GRADE: AISI 303 / 304 / 304L / 316 / 316L / 316TI / 310 / 310S / 321 /430 MEASUREMENT: THICKNESS : 0.40 mm - 6 mm WIDTH: 350 mm - 1600 mm FINISH: 2B, BA, 3N, 4N, 5N, SCOTCH BRITE, HAIRLINE, DUPLO - NARROW COILS GRADE: AISI 303 / 304 / 304L / 316 / 316L / 316TI / 310 / 310S / 321 /430 MEASUREMENT: THICKNESS : 0.30 mm - 3 mm WIDTH: 210 mm - 900 mm FINISH: 2B, BA, 3N, 4N, 5N, SCOTCH BRITE, HAIRLINE, DUPLO - STRIP COILS GRADE: AISI 303 / 304 / 304L / 316 / 316L / 316TI / 310 / 310S / 321 / 430 MEASUREMENT: THICKNESS: 0.30 mm – 3 mm WIDTH: 10 mm - 210 mm FINISH: 2B, BA, 3N, 4N, 5N, SCOTCH BRITE, HAIRLINE, DUPLO

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 436 is a corrosion and heat resistant ferritic Chromium Steel. It can be polished to appear similar to Chromium plate. The material is magnetic in both annealed and cold rolled tempers. This grade of ferritic stainless steel has shown a greater resistance to ridging or roping defects as compared to type 430 stainless steel. The alloy can be readily blanked and formed. The material can be resistance welded, brazed, and soldered. SS 436 is resistant to atmospheric corrosion and fresh water, but it not resistant to most salts and seawater. It is resistant to scaling by oxidation up to about 1400°F. Available Sizes: SS 436 is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.050” (0.0254 mm to 1.27 mm) in widths up to 15.0” (381 mm). The material conforms to ASTM A240 and UNS S43600.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 430 is a corrosion and heat resistant ferritic Chromium Steel. It can be polished to appear similar to Chromium plate. The material is magnetic in both annealed and cold rolled tempers. The alloy can be readily blanked and formed. The material can be resistance welded, brazed, and soldered. SS 430 is resistant to atmospheric corrosion and fresh water, but it not resistant to most salts and sea water. It is resistant to scaling by oxidation up to about 1400°F. Available Sizes: SS 430 is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.050” (0.0254 mm to 1.27 mm) in widths up to 12.0” (304.8 mm). The material conforms to ASTM A240, FED QQS 766, and UNS S43000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 420 is a heat treatable martensitic chromium stainless steel. Melt practice is controlled to develop a surface nearly free from defects. It provides the best combination of wear resistance and corrosion resistance, and is used in demanding medical accessories, such as high quality surgical instruments. The alloy can be cold formed from the annealed temper.Welding should be accomplished by pre and post heating.Pre-heating at 450° F and post-heated at 1300° F will prevent cracking. The corrosion resistance is optimized in the heat treated temper and assured by passiviation. It is resistant to water and organic materials. Oxidation resistance remains favorable in most applications up through 1200°F.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 410 is a heat treatable martensitic chromium stainless steel. Melt practice is controlled to develop a surface nearly free from defects. It provides the best combination of wear resistance and corrosion resistance, and is used in demanding medical accessories. The alloy can be cold formed from the annealed temper. Welding should be accomplished by pre and post heating. Pre-heating at 450° F and post-heated at 1300°F will prevent cracking. The corrosion resistance is optimized in the heat-treated temper and assured by passivation. It is resistant to water and organic materials, making it a good material to use in applications such as, rotary dies. Oxidation resistance remains favorable in most applications up through 1200°F.

Request for a quoteResults for

Stainless-steel strip - Import exportNumber of results

87 ProductsCountries

Company type

Category

- Stainless steels (27)

- Pipe and tube fittings - ferrous metal (24)

- Steel & Metals (14)

- Cold rolled steel strips (6)

- Metal brushes (3)

- Steel sheets and strips (2)

- Pipes and tubes, stainless steel (2)

- Steel, carbon (1)

- Cosmetics (1)

- Fasteners, metal (1)

- Letter boxes (1)

- Petrochemical industry - installations and equipment (1)

- Pipes and tubes, aluminium (1)

- SMALL METAL PARTS (1)

- Seals (1)