- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel strip on rolls

Results for

Steel strip on rolls - Import export

HFP BANDSTAHL GMBH & CO KG

Germany

State-of-the-art technology and extensive knowledge in the processing of steel characterise our location in Bad Salzungen, Germany. For us, performance means a wide range of cold-rolled steels of the highest quality at competitive prices, flexibility and a high degree of readiness to deliver while adhering precisely to the specified chemical and mechanical values. Surface finishing by electrolytic galvanizing and/or subsequent customisation of your goods are possible for us. We offer all our customers spooled materials with volumes of over 200,000 metres of metal strip per spool. This further development means a considerable advantage for our customers. Personnel-intensive set-up times and machine downtimes are avoided.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

This material group comprises C-steel with low carbon content, good formability and fineblanking quality. Due to case hardening, the components have low-wear surface layers with high hardness and sufficient toughness in the core. They thus combine numerous properties and application possibilities in a wide variety of industries. To increase the wear resistance, you can also carburize or carbonitrate partial areas. C 10 E, C 15 E /➔ according to DIN EN 10132 - 2 Depending on the customer's requirements, we supply treatment states from soft annealed to high cold solidified.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Cold rolled strip is used in a variety of applications. It meets high demands on forming behaviour, dimensional tolerances and surface finish, which offers our customers decisive advantages! HFP cold rolled strip is ideally suited for all stamping, bending, drawing and deep drawing purposes. From ball bearing housings to roll cutting and punching strips, hose clamps, headlight reflectors, electrical equipment, office supplies and tubes to safety parts of all kinds, a wide variety of components can be manufactured for various industries. DC 01, DC 03, DC 04 according to DIN EN 10139 / mild steel - St 37/ special grades on request Depending on the customer's requirements, we supply treatment states from LG to C690.

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

ILK IHRACAT AS.

Turkey

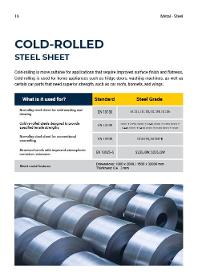

Hot rolled and acid cleaned sheet is enriched by special processes. It reaches the desired thickness by reversible or tandem rolling. At this stage, the sheet is hardened, but becomes formable by continuous annealing or batch annealing. Tempering is applied to improve its mechanical properties. Quality control is ensured through tests and the tempered sheet is shipped in accordance with customer requirements. Cold Rolled Steel Sheet, which is obtained by re-rolling hot rolled and pickled products, has precise dimensions and high surface quality. Product Specifications: DC01, DC03, DC04, DC05, DC06 DC01EK, DC04EK, DC01ED, DC04ED HC260LA, HC320LA, HC380LA, HC420LA Application Areas: Automotive, White Goods, Machinery Manufacturing, Building Industry, Industrial Warehouse Solutions, Panel/Radiator, Fasteners. As Steeling.net, we bring together quality and diversity in cold rolled sheet and offer the highest level of value to our customers.

Request for a quote

EUROPONTEX IMPORTAÇÂO & EXPORTAÇÂO

Portugal

- Wide range of steel grades: structural, cold forming, HSLA, etc. - In coils or cut-to-length - Standard os curtomized sizes

Request for a quote

STAINLESS BAND LTD

United Kingdom

Stainless Band has in house rolling facilities to produce temper rolled strip in various hardness or tensile to suit client requirements. Stainless Band Ltd has in-house rolling facilities to flatten and produce temper rolled stainless steel strip to suit client requirements. These are available in various hardness or tensiles to reduce cross camber or “D” Section. For higher tensile over 1000n/mm2 (330vpn) we can supply precision mill material. Our production capacity for stainless band temper rolled strip is 0.10mm up to 2.0mm with a hardness range of 0.1mm up to 2.0mm with VPN ranges TR 230, TR 280, TR330, TR380 and TR430 and tensile ranges of 800+ 1000+ 1200+ 1500+ and 1900+ n/mm2. Stock grades are 430, 301, 304 and 316. Our production capacity for stainless band flattening provides a gauge range: 1.00mm up to 3.0mm, with a width range: from 10mm to 110mm, stock grades: 430, 301, 304 and 316

Request for a quote

STAINLESS BAND LTD

United Kingdom

Stainless Band has in house rolling facilities to produce temper rolled strip in various hardness or tensile to suit client requirements. Stainless Band Ltd has in-house rolling facilities to flatten and produce temper rolled stainless steel strip to suit client requirements. These are available in various hardness or tensiles to reduce cross camber or “D” Section. For higher tensile over 1000n/mm2 (330vpn) we can supply precision mill material. Our production capacity for stainless band temper rolled strip is 0.10mm up to 2.0mm with a hardness range of 0.1mm up to 2.0mm with VPN ranges TR 230, TR 280, TR330, TR380 and TR430 and tensile ranges of 800+ 1000+ 1200+ 1500+ and 1900+ n/mm2. Stock grades are 430, 301, 304 and 316. Our production capacity for stainless band flattening provides a gauge range: 1.00mm up to 3.0mm, with a width range: from 10mm to 110mm, stock grades: 430, 301, 304 and 316.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

At AMETEK Specialty Metal Products we produce high purity nickel-iron alloy strips, which are primarily used for reed switch systems. These products are widely used in the automotive market for BMS (Battery Management Systems), improved safety in proximity sensors, and cable harness testing. Alloys Our strips are produced using nickel-iron compositions, making sure to use source metals with market leading low levels of trace elements. Alloys include: Nickel-Iron compositions from 36% to 65% Nickel. Sizes Strip thicknesses down to 0.002” (0.0508mm) and wire diameters as small as 0.005” (0.127mm). Applications Finished nickel-iron alloy reed switch systems are used within a multitude of products and devices, mainly being used in the Automotive and Electronics industries. Automotive: BMS (Battery Management Systems), automatic braking assists, door sensors and speedometers.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Automotive safety systems need to be reliable, accurate, and capable of saving lives. We work closely with automotive component suppliers worldwide to develop custom metal strip materials that enhance performance and safety. Precision Engineered Strip for the Automotive Industry You’ll find our strip products in many critical automotive systems in today’s vehicles including: Reed switch systems Nickel strip for EV battery connectors Electronic Connector Materials High Performance Automotive Alloys Nickel-iron compositions from 36% to 65% nickel High purity nickel Strip Spinodal alloys Safe and Efficient Automotive Material Solutions Our metallurgists engineer custom material solutions using the highest quality alloys to ensure maximum automotive performance, reliability and safety.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products has built a reputation for first class product quality and reliability. That’s why leading defense programs use our high-performance materials. Leadership in Defense Metals We have more than 50 years of experience developing precision strip and thermal management products for critical defense applications worldwide. Our defense portfolio includes: Thermal management materials for semiconductor heatsinks Nickel strip for battery connectors High Performance Defense Alloys Molybdenum Copper (AMC) and Tungsten Copper (AWC) High purity nickel strip Trusted for Critical Defense Applications Due to their excellent thermal conductivity and controlled thermal expansion, our Molybdenum-Copper and Tungsten-Copper composites are the preferred materials for Gallium Arsenide (GaAs) and Gallium Nitride (GaN) semiconductors for the defense industry. Our heat spreader materials are trusted in sensitive applications such

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products has built a reputation for first class product quality and reliability, and that’s why so many leading commercial and defense aviation programs use our high performance materials. 50 years Aerospace Expertise We have more than 50 years experience developing precision strip, wire and shaped component products for critical aerospace applications worldwide. Our aerospace portfolio includes: High Tolerance Custom Shaped Wire for Aircraft Push-Pull Controls Pfinodal® (C72900) Bearing Material for Landing Gear Bushings and Bearing Sleeves Specialty Shaped Wire for Lock Collar Tape used in Aerospace Rivets Highly Conductive Nickel Strip for Aerospace Electronic Connectors, Batteries, Heat Exchangers and Bellows. Lighter and Stronger Materials for Aircraft Performance At 35,000 feet, every detail matters. We’re dedicated to manufacturing precision, lightweight and high strength materials to enhance the performance and efficiency of aircraft worldwide.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Precision re-rolled stainless steel strip products can be engineered to specific customer requirements with exceptionally short lead times. Based on our longstanding expertise, we can manufacture stainless steel strip to precise custom sizes, ultra-thin gauges and tightly controlled mechanical properties with any surface finish. We also work closely with Hamilton Precision Metals, part of AMETEK Specialty Metal Products, to produce stainless steel foils down to 1.5 microns (.000060”) thickness. Standard Alloys We manufacture stainless steel strip in a variety of chemical and mechanical properties, expertly engineered to your exacting specifications. High performance stainless steel strip material includes: Austenitic: 300 series Martensitic: 400 series Ferritic: 400 series PH Grades 17-7PH®, 17-4PH® Additional options available on request

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products uses a wrought powder metallurgical process to ensure the highest purity finished products. Our main strengths lie in the processing of Nickel, Iron and Cobalt containing alloys amongst other available materials. The processing of these materials begins with the consolidation of powder through a roll compaction process and followed by a controlled atmosphere sintering. Further reduction of the material is performed solely under cold working temperatures to reduce the introduction of non-metallics and annealing is performed under controlled atmospheres. AMETEK Strip Products are produced in ranges between .002” (0.05mm) and .080” (2.03mm) thicknesses in a full range of tempers and widths to 22” (558.8mm) while maintaining special capabilities to produce materials outside of these ranges for special applications. This process lends itself to the production of small but easily reproducible lots of highly specialized alloys

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Unalloyed Tantalum is supplied to ASTM F560 – R05200 composition limits. Tantalum is selected for its corrosion resistance, thermal conductivity, high melting point, and ability to form a dielectric oxide film. Tantalum is very ductile and can be readily cold formed due to a low work hardening rate. Welding can be accomplished via resistance, TIG, or electron beam methods, with care taken to protect the weld and heat affected zone from air during welding. Because of the potential for hydrogen embrittlement, Tantalum can not be used for extended service in air or other oxidizing atmospheres above 260°C unless a protective inert atmosphere or vacuum is provided. Available Sizes: Tantalum is available from Hamilton Precision Metals as strip product from 0.0005” to 0.035” (0.0127 mm to 0.889 mm) in widths up to 12.0” (304.8 mm). The material conforms to UNS R05200 and meets the requirements of ASTM F560 and ASTM B708.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Constantan® is a copper-nickel alloy that contains specific minor amounts of additional elements to achieve precise values for the temperature coefficient of resistivity. Careful control of melting and conversion practices results in a very low level of pinholes at ultra-thin thicknesses. The alloy is used extensively for foil resistors and strain gauges. The TCR can be adjusted from the furnished cold rolled values by using a low temperature heat treatment to achieve compensation for all types of spring elements. The foil is normally supplied with 90% cold reduction and a smooth bright surface. The foil is reasonably flat at 4” wide and nearly free of pinholes. The cold rolled foil can be produced with a TCR between +10 to –35 PPM/°C. The heat treatment will shift the foil TCR to the desired value. A typical heat-treat curve for Constantan® shows decreasing resistivity but increasing TCR with increased heat-treating temperature.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Ti Grade 9 is a near alpha, alpha-beta alloy, sometimes referred to as “half-6-4.” It offers 20 to 50% higher tensile strength than the commercially pure titanium at room and elevated temperatures. It is much more amenable to cold working than Ti 6AI/4V alloy and can be cold worked 75 to 85% to result in moderately high strength and good ductility The alloy can be formed from the annealed temper. Severe forming may be aided by an intermediate stress relief. Stress relieving may be appropriate after severe cold forming to remove residual stresses. Weldability and corrosion resistance is very similar to commercially pure titanium. Welding should be performed with inert gas shielded arc or spot welding.Welding with active gases, coatings, or fluxes must be avoided to prevent embrittlement.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMETEK SPECIALTY METAL PRODUCTS

United States

Here at Hamilton Precision Metals, we’re passionate about cold rolling metal strip in a diverse range of specialty alloys to meet your exacting specifications. Our extensive precision strip product range include stainless steel strip, nickel strip, titanium strip, copper based strip, cobalt based strip and many more alloys. We have the expertise to roll light gauge strip from 1.5 mm (.060”) down to 0.127 mm (0.005”). Broadest Range of Alloys We offer an extensive portfolio of almost every high performance alloy made today. Additional alloys are available upon request, contact us today! Stainless Steels Nickel Based Alloys Copper Based Alloys Cobalt Based Alloys Commercially Pure Titaniums Strain Gage: Constantan®, Evanohm®,

Request for a quote

IMT MACHINERY

Turkey

Guard rails (Road Safety Barriers) and its auxiliary elements, for use in highways and special purposes, are manufactured at our lines.

Request for a quote

FRIEDR. GUSTAV THEIS KALTWALZWERKE GMBH

Germany

Our cold-rolled steel strip is mainly used where particularly high requirements have to be fulfilled: -Quality - Dimension tolerances - Mechanical technological properties - Structural compositions - High-quality surfaces As a long-standing partner of the automotive industry we have for decades provided a considerable amount of our cold-rolled steel strip to renowned international automotive manufacturers and their sub-suppliers. There our material is reshaped using punching, bending, drawing and deep-drawing processes. Another important sector of our clients are renowned manufacturers of safety components, electrical equipment, pipes, profiles, pressure vessels, nuclear plants and manufacturers of a wide variety of other industrial products. They all appreciate our comprehensive selection and combination of technical processes and working materials. We support our clients’ product development. With efficient manufacturing processes, the continuous further development of our technologies, broad range of services and comprehensive consulting expertise.

FRIEDR. GUSTAV THEIS KALTWALZWERKE GMBH

Germany

With our own plant at Hagen we finish the basic material for our clients. Electrolytically galvanized in matt or glossy finish and, if required, subsequently phosphated and/or chemically passivated. In addition we can chemically phosphate in accordance with the bonding process. The technological properties of the carrying strip are completely retained during this process. Hence the primary material and the surface finishing produce a high-quality material, which you can easily process and use for many purposes. Details of the properties: - High corrosion-resistance - Best painting capabilities - Decorative appearance - Uniform, homogenous layer thicknesses (1-15 my / side) - Low reject rates - No longer high unit finishing costs - Avoidance of environmental problems - Good deep-drawing behaviour

FRIEDR. GUSTAV THEIS KALTWALZWERKE GMBH

Germany

Stainless, acid-resistant, heat-resistant: no wonder that many clients rely on our THENOX® precision steel strips. The premium flat product made of corrosion-proof stainless steels is produced from hot-rolled steel strip in a cold rolling process. In detail: Through the main alloy element, chrome, a protective layer of chrome oxide is formed on the surface of the austenitic, ferritic and martensitic steels: this gives the material a permanent metallic appearance. Even in chemically aggressive substances. Other carefully alloyed elements, such as nickel, molybdenum and titanium, improve the corrosion resistance and – depending on the alloy – give the different types of steel the required technological properties: for instance good deep-drawing, bending or punching capabilities, or increased elasticity values. We roll steel in thicknesses from 0.05 to 1.50 mm with widths from 3 to 650 mm.

OREMUS S.R.O.

Czech Rep.

Our four-cylinder rolling machines offer a maximum width of 1900 mm, and pipe twisting up to a diameter of 220mm at max. 6mm gage. In smaller versions 1000mm, for diameter min. 125mm

Request for a quote

COLORICIO.SRL

Romania

Coloricio offers a wide range of flat and rolled products that prevents steel rust and corrosion through excellent surface finish related to zinc coating: cold-rolled steel/aluminum hot rolled (pickled and oiled) steel/aluminum hot dip galvanized steel/aluminum

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 436 is a corrosion and heat resistant ferritic Chromium Steel. It can be polished to appear similar to Chromium plate. The material is magnetic in both annealed and cold rolled tempers. This grade of ferritic stainless steel has shown a greater resistance to ridging or roping defects as compared to type 430 stainless steel. The alloy can be readily blanked and formed. The material can be resistance welded, brazed, and soldered. SS 436 is resistant to atmospheric corrosion and fresh water, but it not resistant to most salts and seawater. It is resistant to scaling by oxidation up to about 1400°F. Available Sizes: SS 436 is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.050” (0.0254 mm to 1.27 mm) in widths up to 15.0” (381 mm). The material conforms to ASTM A240 and UNS S43600.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 430 is a corrosion and heat resistant ferritic Chromium Steel. It can be polished to appear similar to Chromium plate. The material is magnetic in both annealed and cold rolled tempers. The alloy can be readily blanked and formed. The material can be resistance welded, brazed, and soldered. SS 430 is resistant to atmospheric corrosion and fresh water, but it not resistant to most salts and sea water. It is resistant to scaling by oxidation up to about 1400°F. Available Sizes: SS 430 is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.050” (0.0254 mm to 1.27 mm) in widths up to 12.0” (304.8 mm). The material conforms to ASTM A240, FED QQS 766, and UNS S43000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 420 is a heat treatable martensitic chromium stainless steel. Melt practice is controlled to develop a surface nearly free from defects. It provides the best combination of wear resistance and corrosion resistance, and is used in demanding medical accessories, such as high quality surgical instruments. The alloy can be cold formed from the annealed temper.Welding should be accomplished by pre and post heating.Pre-heating at 450° F and post-heated at 1300° F will prevent cracking. The corrosion resistance is optimized in the heat treated temper and assured by passiviation. It is resistant to water and organic materials. Oxidation resistance remains favorable in most applications up through 1200°F.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 410 is a heat treatable martensitic chromium stainless steel. Melt practice is controlled to develop a surface nearly free from defects. It provides the best combination of wear resistance and corrosion resistance, and is used in demanding medical accessories. The alloy can be cold formed from the annealed temper. Welding should be accomplished by pre and post heating. Pre-heating at 450° F and post-heated at 1300°F will prevent cracking. The corrosion resistance is optimized in the heat-treated temper and assured by passivation. It is resistant to water and organic materials, making it a good material to use in applications such as, rotary dies. Oxidation resistance remains favorable in most applications up through 1200°F.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 316L is an austenitic Chromium-Nickel stainless steel with superior corrosion resistance. The low carbon content reduces susceptibility to carbide precipitation during welding. This permits usage in severe corrosive environments such as isolator diaphragms, and metal diaphragms, for both aerospace sensors and burst discs. The alloy can be formed from the annealed temper by stamping and deep drawing. Joining is accomplished by brazing and welding. The Molybdenum is the alloy composition provides excellent strength up through 800° F in applications. Available Sizes: SS 316L is available from Hamilton Precision Metals as strip product from 0.0005” to 0.050” (0.0127 mm to 1.27 mm) in widths up to 12.0” (304.8 mm). It is also available in foil as thin as 0.000200” (0.00508 mm) in widths of 4.0” (101.6 mm) maximum. The material conforms to AMS 5507, ASTM A240, FED QQS766 and UNS S31603.

Request for a quoteResults for

Steel strip on rolls - Import exportNumber of results

39 ProductsCountries

Company type