- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welded pipes

Results for

Welded pipes - Import export

BASE GROUP SP Z O.O.

Poland

We manufacture constructions for energy in accordance with ISO 3834-2 and other certificates. The quality of our welded pipes is certified by the positive audit assessments. Certification body have qualified us as the supplier of the company which is the leader in the global energy market. We produce wide range of steel pipes for equipment of electric power production and transmission.

Request for a quote

COLORICIO.SRL

Romania

We supply round, square, hexagonal and flat barsteel in a broad range of dimensions and steel qualities, includes seamless and welded pipes and tubes according to EN, ASTM and API standards, in a wide variety of steel qualities. They are selected by construction, production and industrial companies due to their durability and multi-purpose use. Our extensive offer allows you to select the most optimal variant for your needs

Request for a quote

COLORICIO.SRL

Romania

Coloricio offers a wide range of flat and rolled products that prevents steel rust and corrosion through excellent surface finish related to zinc coating: cold-rolled steel/aluminum hot rolled (pickled and oiled) steel/aluminum hot dip galvanized steel/aluminum

Request for a quote

METAL IN LTD

Bulgaria

Metal In put into operation a machine for laser cutting of pipes with automatic loading and unloading. The size of the treated pipes is: Round pipes: 120 mm Rectangular tubes: 100x100mm The maximum length of the workplace is 6500mm. The machine is equipped with excellent software that allows different shapes in tubes for subsequent assembly and welding. Also, pipes can be cut so that one wall remains uncut, allowing it to bend easily and accurately and find a frame.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is a welded pipe made of stainless steel,mainly used for connect both of the two sides od the products.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel flanges are a crucial component in various piping systems, providing ease of assembly and strength in connecting pipes, valves, pumps, and other equipment. They serve as a plate for covering or closing the end of a pipe and are commonly used in plumbing, oil and gas, petrochemical, and food industries due to their durability and corrosion resistance. Types and Specifications Stainless steel flanges come in several types to suit different applications: Weld Neck Flanges: Designed to be welded to the pipe. Suitable for high-pressure applications. Slip-On Flanges: Easily slide over the pipe and are welded in place. Socket Weld Flanges: Used for smaller, high-pressure piping. Threaded Flanges: Attached without welding, ideal for low-pressure applications or pipes with a thin wall. Blind Flanges: Used to seal the end of piping systems or pressure vessel openings. Lap Joint Flanges: Used with stub end fittings for applications requiring frequent dismantling.

Request for a quote

COPIER MACHINERY

Netherlands

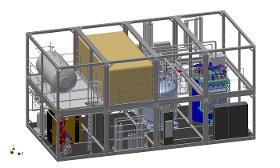

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

COPIER MACHINERY

Netherlands

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

ERATEC

France

Preheating of forging tools Preheating of tubes before welding Preheating before thermal spraying Preheating of moulds

Request for a quote

MAGNITO EU LTD.

Bulgaria

Steel legs in X shape, cross welded steel pipes, powder painted, produced from rectangular steel pipe 30 mm x 60 mm, 1 unit heavy-duty metal plate with 12 holes. The base is equipped with adjustable leg leveling glides for perfect adjustment on the floor. All our products are Made in Europe.

Request for a quote

MAGNITO EU LTD.

Bulgaria

Training room table legs in T or C shape, welded construction, powder painted, steel pipe with diameter 51 mm, 1 unit heavy-duty metal plate with 10 holes. The legs are equipped with adjustable leg leveling glides for perfect adjustment on the floor. Possible delivery with casters for easy position change. 2 units in one set. All our products are Made in Europe

Request for a quote

MAGNITO EU LTD.

Bulgaria

T legs for training rooms, steel welded construction, powder painted, steel pipe with diameter 51 mm, 1 unit heavy-duty metal plate with 10 holes. The legs are equipped with adjustable leg leveling glides for perfect adjustment on the floor. Possible delivery with casters for easy position change. 2 units in one set. All our products are Made in Europe.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

The advantages to you: no more deformation of roundness when cutting bends on site easier extension-pipe/tiered pipe bend construction appealing visually pickled surface All of our pipes and pipe bends (both unannealed and annealed) are made of the following material: stainless steel pipe, material no. 1.4301 (AISI 304) longitudinal seam welded pipes hot rolled & cold rolled coils, unannealed, with or without pickling (W1) Make: IltaInox and/or Marcegaglia

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1019 series are lightweight cylinders where weight is of crucial importance. They were designed for the areas of mobile hydraulics, crane and aerial work platform construction. All cylinders work with low friction and are characterized by a stick-slip-free run. Lift and piston rod overhang are variable selectable. The cylinder connection is via plain bearing bushes. Connections are provided on the valve plate or a control block, which are flanged to the cylinder via welded pipes, in accordance with DIN EN 280. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the...

Request for a quote

CMPLAST

Poland

Is the second most frequently used metal after iron. It has high corrosion resistance in marine and industrial environments. It is characterized by high fatigue strength, it is susceptible to welding and anodizing. Aluminum is used in many industries mainly in shipbuilding, chemical, food, household appliances, architecture, construction and the automotive industry. It is used for elements of transport, for welded constructions, pressure tanks, piping elements, pneumatic and hydraulic lines. Details made of aluminum can be anodized and powder coated at your request

Request for a quote

ANTHERMO GMBH

Germany

Swept outlet similar to ANSI B 16.19 / ANSI B 36.10 Swept outlets in pipeline construction A swept outlet is used in pipeline construction just like a welding outlet, a socket welded outlet or a threaded outlet for a 90 ° branch. A swept outlet is an alternative to the T-piece / red. In comparison to the T-piece / Red.Tee, the installation effort for a swept outlet is lower because only one hole has to be drilled into a pipe. The swept outlet can then be welded into this hole. A swept outlet differs from a welding outlet in the type of welding. While a welding outlet is only placed on the run pipe and then welded, a swept outlet is welded directly into the run pipe. Ideal stress distribution Swept outlets were developed in order to achieve the best possible stress distribution for internal pressure and pipe forces. Due to the favorable voltage level, swept outlets are often used in highly stressed pipes in the oil and gas industry.

Request for a quote

KASAG SWISS AG

Switzerland

We bring your ideas to life KASAG has a high level of competence, with many years of experience in design and construction of plants, apparatuses, pressure vessels, pipes and welded structures. Our engineers can assist you with the following: Strength calculation according to the global regulations, such as PED (EN13445 / AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) FEM-calculations (Finite element analysis) and providing proof for overpressure and underpressure, load alteration, earthquake, joint flanges, nozzle loads Consultancy for interpreting and analyses of computation results, material choice, regulatory authorities Constructive, design based on Autocad 2D and Inventor 3D Comprehensive plants engineering, such as compilation of technical specifications, P&I schemes, risk analyses, pipeline/piping planning

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANKARA BRONZ

Turkey

With a simple fusion, two parts can be combined. Large and heavy parts such as blocks and pipes can be welded using eutectic and tin-lead solder or melting alloys with low fusion points. CORROSION FEATURES Resistant to distilled, salty and fresh water. Affected by strong acids, alkalis and acid salts. Oxygen presence in solution increases response speed.

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

This extremely robust flat-panel detector was specially designed for mobile use and the harsh conditions of industrial radiography and can be used with X-ray and gamma sources. With its active area of 23.0 x 28.8 cm, excellent contrast and uniquely high resolution thanks to a pixel pitch of 75 µm, even the most demanding inspection tasks can be mastered. - Weld seam inspection - Pipe inspection, corrosion inspection, erosion inspection - Crack detection - Casting inspection

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in aluminum tube bending services more than 10 years, we have produced various types of aluminum tube bending fittings from different, include welded tube and seamless pipe, Elliptical tube and rectangular tube. we produce tube bending components from materials of stainless steel tube, aluminum tube, carbon steel tube, brass & copper tube. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge machine, precision pipe cutting machine, welding machine, drilling Machine, etc. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge mac

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Pipe / tube fabricating services more than 10 years, we have produced various types of aluminum pipe bending fittings from different, include welded pipe and seamless pipe, Elliptical tube and rectangular tube. we produce Pipe / tube bending components from materials of stainless steel tube, aluminum tube, carbon steel tube, brass & copper tube. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge machine, precision pipe cutting machine, welding machine, drilling Machine, etc. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge mac

Request for a quote

AVK REWAG

Netherlands

The Repico® SD – Slip type coupling two locks is designed to replace traditional pipe joining methods(welded, flanged, threaded etc.). Sealing against 10.7 bar (165psi) maximum and it has a progressive sealing. Max. angular deflection 5°. Completely made out of stainless steel 316. Green PTFE coated bolts. No special tools or skilled people are required to install the Repico® pipe couplings. Light weight appr. 30% in comparison with flanged connections. Quick to install (minutes). It requires limited space for installation, just a bit bigger than the pipe OD. Connects different materials. No transition couplings required, allows pipe section replacement. 60% noise reduction compared to rigid connections.

Request for a quote

AVK REWAG

Netherlands

The Repico repair couplings offer solutions to repair leaking pipes, elbows and welds. The pipe can be damaged or the integrity has degraded. This can be a temporary or permanent repair. All repair couplings have hinges or locks allowing the clamp to be “wrapped” around the damaged area. It requires less space than the traditional repair clamp, is able to resist higher pressures and is easier to install. A repair coupling offers a quicker solution than replacing a pipe section and much less cost is involved. Spills into the environment or loss of valuable products can be stopped faster than most other methods offering a high integrity solution. Having several of them in stock can resolve unwanted situations by just torqueing a few bolts. The RH type has 1 lock and 1 hinge, it opens as a shell and “wraps” around the pipe. Analogue to the Slip type we also offer a 2, 3 and 4 lock configuration in the repair version. To repair long radius elbows we offer a 1 bolt version of the...

Request for a quote

AVK REWAG

Netherlands

The Repico® Grip type coupling is designed to replace traditional pipe joining methods (welded, flanged, threaded, etc.). The Grip type pipe coupling offers a tensile or restraint connection between the pipes. This means that there is a leak free connection made and the pipes are held in position inside the coupling. A grip ring holds the pipe within the coupling. Of course any type of pipe material that can withstand the sealing pressure of the coupling can be connected. Note that there are different versions for metallic and plastic pipes. No special tools or skilled people are required to install the Repico® product program. The pipe ends only need to be deburred and cleaned. The bolts tightened evenly and torqued with a torque wrench ensures a secure and durable connection. The Repico® grip range has the following types: GLP, GMP, G, GF, please see their specifications in the separate sections.

Request for a quote

AVK REWAG

Netherlands

The Repico® slip type coupling is designed to replace traditional pipe joining methods (welded, flanged, threaded, etc.) The Repico Slip type pipe coupling offers a non-tensile or non-restraint connection between the pipes. This means that there is a leak free connection made and the pipes are not held in position inside the coupling. Contraction and/or expansion of the pipe material can be handled within the coupling. Any type of pipe material that can withstand the sealing pressure of the coupling can be connected. Material that is not strong enough or has the tendency to shrink should be supported by a support bush (insert or stiffener). No special tools or skilled people are required to install the Repico® product program. The pipe ends only need to be deburred and cleaned. The bolts tightened evenly and torqued with a torque wrench ensures a secure and durable connection. The Repico® slip range has the following types: S, SL, SF, SD, SDL, SDF, ST and SQ, please see their...

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in aluminum tube bending services more than 10 years, we have produced various types of aluminum tube frames, tube bent fittings, include welded tube and seamless pipe, Elliptical tube and rectangular tube. we produce tube bending components from materials of stainless steel tube, aluminum tube, carbon steel tube, brass & copper tube. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge machine, precision pipe cutting machine, welding machine, drilling Machine, etc. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge mac

Request for a quote

DELTAFLUID

France

The monoblock diaphragm and the ISA1932 monoblock nozzle are made from a solid round. The pressure taps are directly machined in the monoblock. They can be simply machined (pressure tapping holes) or supplied with nipples to connect directly to your installation. This type of diaphragm or nozzle has the advantage of being simple to install: simply mount it between single flanges or weld directly on the pipe for a version to be welded. All types of edges (sharp-edge, conical, quarter-circle, eccentric, segmental and multi-hole) can be made in a single-piece version. Flanged or corner pressure taps can be made in monoblock version.

Request for a quote

AHP PLASTIK MAKINA

Turkey

for guiding welder during weld process and recording welding data also printout of data to excel file and thermal printer included

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

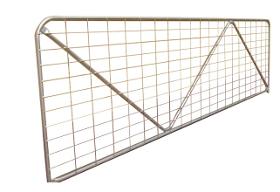

-Material:Hot-dip galvanized Steel Pipe or Square Tube -Finish:Galvanized or Powder coating -Height × Length:Customized -Frame Pipe:32mm OD / 40mm OD / 42mm OD -Infill Wire Rod:φ5mm / φ6mm -Length:Customized -Height:Customized -Welding:Fully welded -Connecting:Round pipe lugs & pins

Request for a quoteResults for

Welded pipes - Import exportNumber of results

81 ProductsCountries

Company type

Category

- Pipes and tubes, steel (9)

- Welding, electric - equipment and supplies (6)

- Pipes and tubes, stainless steel (4)

- Animal Production (3)

- Laser - cutting and welding machines (3)

- Metallurgy and iron and steel industry - machinery and installations (3)

- Monitoring and control equipment (2)

- Pipe and tube fittings - ferrous metal (2)

- Pipe and tube fittings - non-ferrous metal (2)

- Temperature sensing devices (2)

- Steels and metals - welding and brazing (1)

- Agricultural machines and accessories (1)

- Air-conditioning systems, vehicles (1)

- Aluminium and aluminium alloys (1)

- Aluminium coatings (1)

- Brushes and paint brushes (1)

- Burners, industrial (1)

- Car tuning equipment (1)

- Components and parts for small household appliances (1)

- Computer furniture (1)